The working conditions of sewage nullahs are characterized by large fluctuations in water quality, low ambient temperatures and foam accumulation on the water surface, etc. Due to the complex working conditions, it is not particularly easy to choose the right level meter. Today we will analyze the characteristics of several level meters to see which is the most suitable for measuring sewage nullahs.

Firstly, the ultrasonic level meter, which uses non-contact measurement, is suitable for the measurement of liquids, solids, and toxic media. The measurement principle is that the transmitter emits ultrasonic pulses, which reach the liquid surface to form a reflected wave, which is then received by the receiver.

The timing circuit measures the propagation time of the transmitted and reflected waves, as well as the propagation speed of the sound waves, and the level height is calculated.

Ultrasonic level meters have the characteristics of long measuring distance and high accuracy. However, due to the limitations of the measuring principle, the level meter is susceptible to the effects of temperature, humidity, and air pressure.

Under some working conditions, the fluid surface in the sewage nullah is prone to fogging, which can form a fog layer that absorbs and scatters ultrasonic waves and affects the measurement of the instrument; the water surface has dense foam and the ultrasonic level meter needs to have a good reflection of the liquid surface.

When there is foam on the surface of the sewage waiting for floating objects, the acoustic resistance increases and the intensity of the reflected wave weakens or even disappears, thus affecting the measurement results.

Therefore, the ultrasonic level meter is not suitable for this situation.

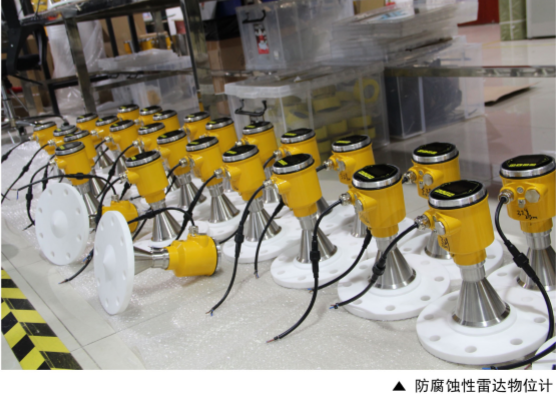

Again, the non-contact radar level meter can continuously measure liquids, slurries, sludges, and solid materials. The radar level meter emits ultra-high frequency electromagnetic waves from the antenna.

When the electromagnetic waves hit the surface of the liquid, they are reflected back and received by the antenna.

The instrument detects the time difference between the emitted wave and the return wave and calculates the level height. In contrast to ultrasonic level meters, electromagnetic waves do not need to travel through the air and the ambient and fluid temperatures do not affect the measurement.

However, due to the measuring principle of radar level meters, they need to receive the reflection of electromagnetic waves in order to complete the measurement. In some open channel projects, a large amount of dense foam has accumulated on the water surface.

Foam can be classified by its nature as dry foam, wet foam, neutral foam, and heavy foam. Dry and wet foams can reflect radar waves back and have little effect on the measurement, but neutral foams can absorb and diffuse radar waves, causing the reflection to be affected, or even absent.

When the media surface is dense foam, the meter cannot measure. A non-contact radar level meter cannot eliminate the effect of foam, so it is not suitable if this is the operating condition.

Finally, the guided wave radar level meter has the characteristics of a non-contact radar level meter, i.e. it is unaffected by temperature, medium density, dust, and vapor, and can also measure when the medium surface is foamy.

The principle of the guided wave radar level meter is that when the probe sends out a high-frequency pulse and propagates along the cable to reach the liquid level surface, the pulse is reflected to form an echo back to the pulse emitting device due to the sudden change in the dielectric constant, and the crossing time of the pulse wave is measured.

The level height can then be calculated. It is suitable for low temperatures, and foaming conditions.

In fact, ultrasonic level meters and radar level meters can generally measure sewage nullahs, but some of the special circumstances mentioned in this article, such as low temperature and the influence of complex foam are not so suitable, but the guided wave radar level meter is the most suitable.

This is also a reminder that the level meter must be selected according to the working conditions in order to ensure the accuracy of the measurement results.