In smelters, the oxygen-pressure leaching process is a relatively new process compared to the conventional and high-temperature, high-acid methods, and naturally, the technology is slightly superior. In this process, various storage tanks are used, of which autoclaves are essential. In order to reduce the labor intensity of the personnel involved, several smelters have installed radar level meters in the tanks.

However, the installation process can also lead to rework. In order to reduce the re-emergence of this situation, the smelter radar level meter installation points, I hope that if necessary, we have tips.

First, during operation, if the medium in the storage tank fluctuates and stirs, the radar level meter can try to lengthen the installation of the conduit, but the premise is that the diameter of the conduit must be larger than the radiation surface of the probe. This method is generally only suitable for small-range storage tanks.

Secondly, if the wall of the tank is smooth, there will be no hanging material when the level rises and falls, and the radar level meter can be closer to the tank wall. But if the tank wall is very rough, the radar level meter probe should be far away from the tank wall.

If the tank has a cone-shaped base, the radar level meter can be considered for installation above the apex of the cone, but when installing it, care must be taken to ensure that no obstacles exist within the radar wave range. If there are obstacles, pay attention to avoid them.

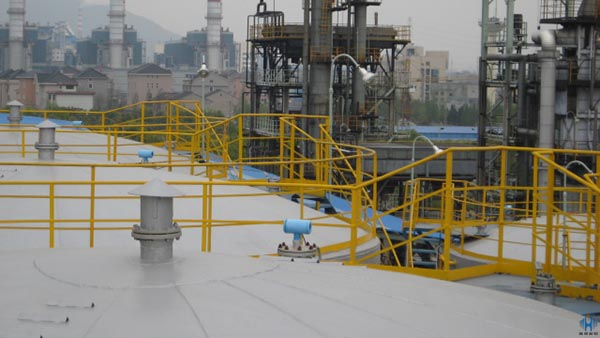

Thirdly, if the radar level meter is installed outdoors, attention should be paid to the installation of sun and rain protection equipment. In summer it rains a lot and the radar level meter head is prone to water ingress. Therefore, when installing, more attention must be paid to avoid affecting the measurement effect.

Fourth, the highest liquid level, can not exceed the measurement of the blind area, this point should be noted, otherwise, it can not be measured to the real liquid level.

Smelters, with many storage tanks, use a variety of level meter types, some enterprises use more ultrasonic level meters, some enterprises use more radar level meters, and some enterprises will also try radio frequency conductivity level meters. Regardless of the type of level meter used, attention should be drawn to the installation. In addition, in order to ensure the normal operation of the measurement, the level meter needs to be regularly maintained and overhauled, and when problems are found, they should be dealt with in a timely manner.