I often hear customers in consultation with the radar level meter, will ask a question, that is, the use of the radar level meter will go wrong in the process. This is often doubting in the minds of the majority of users, in fact, there is no need to worry too much about this issue. People can get sick, let alone instrumentation, the use of the process of problems is a normal phenomenon, the important thing is how to solve through debugging. I will be through the case, divided into two parts to analyze the causes of several radar-level meter failures and processing methods.

The first thing to know about radar level meters is that electromagnetic wave can penetrate the vacuum, does not need a transmission medium, and is not affected by the atmosphere, fog, foam, and hanging material. The measurement accuracy is high, the resolution can reach 1mm: the measurement range is large, and the maximum measurement range can reach 40m, especially suitable for the measurement of tall storage tanks.

Adopting non-contact measurement, it is not affected by various physical characteristics of the measured medium, especially in high temperature, high pressure, corrosive and large steam. It adopts an integrated design structure, no moving parts, no mechanical wear and tear, stable operation, and long service life.

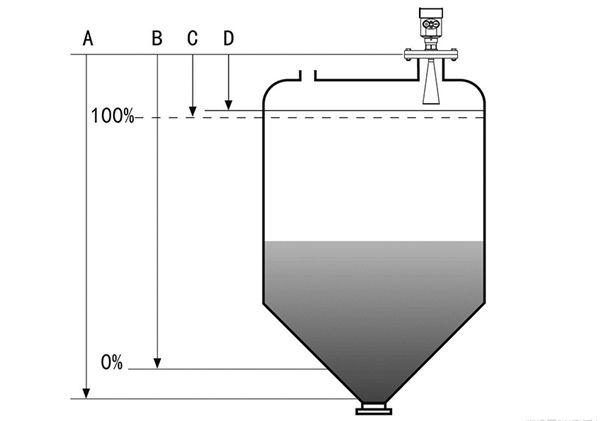

Secondly, the correct installation is also important, radar level meter installation precautions are, the axis of the radar level meter must be perpendicular to the liquid surface to enhance the strength of the reflected wave. A round or oval container should be installed on the top of the tank from the center 1, 2R to prevent the formation of strong interference waves after repeated reflections from the container wall, affecting the accurate measurement. If the liquid level fluctuates greatly, a bypass tube can be installed.

Let’s formally enter today’s topic. First, let’s take a look at the first case, a radar level meter, when in use, suddenly the level kept rising rapidly, and then it didn’t move beyond the range. After finding this problem, the user adjusted the parameters according to the manual and carried out empty tank detection, but without any effect. Later tried to replace it, and after replacement, there was no problem with the following water test.

After careful analysis, it was found that the reason why it could not be detected during use was mainly that the antenna itself was hung with media. The radar level meter is used to detect the level of the benzene tank, and when the temperature is below 6 degrees Celsius, benzene will crystallize and actually freeze. Benzene is also a volatile liquid.

To prevent benzene from freezing in the winter, the process is designed with circulating steam heating in the tank so that benzene will still evaporate in the tank during the winter.

The radar level meter was equipped with insulation and heat tracing, sometimes mounted on a nozzle at the top of the piping at a temperature much lower than the temperature inside the tank, so that in winter, the benzene vapor would condense when it touched the antenna of the level meter, affecting the use of the radar level meter.

When such a problem occurred again later, the plant took the approach of removing the meter and cleaning the antenna.

If the problem occurs in winter, the first thing to consider is insulation and heat tracing. To solve the problem fundamentally, you can consider changing the replacement type.

If you want to measure liquids with condensation, you can consider using a radar level meter with a blowing device, where the wind can blow the transmitting antenna directly from the inside, which can solve this problem.