This series of articles on radar level meter measurement cases can enrich our knowledge base and provide more references and references when facing some measurement problems. The same type or different types of radar level meter, the same or different measurement media, different specific working conditions, measurement in a variety of problems, and then solving the problem is a process of knowledge growth.

Today we share with you a case of a radar level meter measuring liquid alkali, to see what problems there will be in the measurement process and the solution of after-sales engineers.

Before looking at the case, let’s understand what is liquid soda, liquid soda is a kind of sodium hydroxide, that is, liquid sodium hydroxide, pure liquid caustic soda is called liquid soda, colorless and transparent liquid. Pure product is a colorless transparent liquid. Relative density 1.328-1.349, melting point 318.4℃, boiling point 1390℃. Pure liquid caustic soda, called liquid caustic soda, is a colorless and transparent liquid. Most industrial products contain impurities, mainly sodium chloride and sodium carbonate, and sometimes a small amount of iron oxide. After dissolving into the original liquid base, most of the impurities will float to the liquid surface and can be separated and removed. It is an important basic chemical raw material with a wide range of uses.

The chemical industry is used in the manufacture of formic acid, oxalic acid, borax, phenol, sodium cyanide and soap, synthetic fatty acids, synthetic detergents, etc. Textile printing and dyeing industry used as cotton desizing agent, cooking agent, mercerizing agent reduction dyestuff, and the solvent of Haichang blue dyestuff. Smelting industry is used for the manufacture of aluminum hydroxide, aluminum oxide, and metal surface treatment agents. Instrument industry used as an acid neutralizer, decolorizer, and deodorizer. The adhesive industry is used as a starch pasting agent and neutralizer. In addition, it is also widely used in enamel, medicine, cosmetics, leather, paint, pesticide, glass, and other industries.

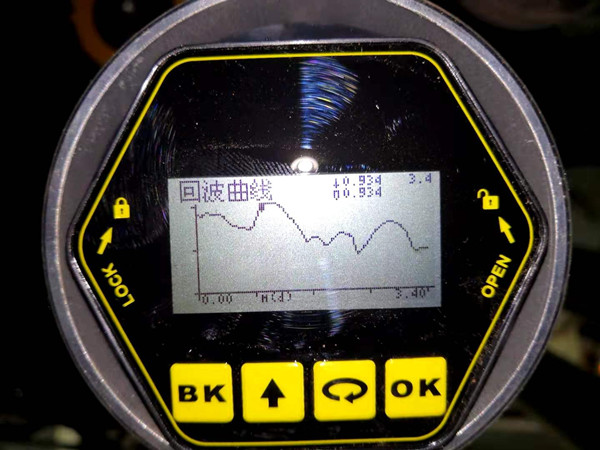

Through the above text, we probably have an understanding of this medium, the following to see the specific actual case. A company in Jiangsu installed and used our radar level meter, model RD902, to measure liquid alkali. The customer responded that the radar level meter had jumped, was unstable, and the a signal fluctuation.

In response to this situation, our technical personnel went to the site to investigate and found that the medium had crystallization and the vapor in the tank was particularly large, which is why the jumping and instability occurred. The technicians thought that the 902 radar level meter was not suitable for this kind of working condition and decisively replaced the RD906 with our company, which can reduce the influence of steam more effectively and thus solve the problem.

We usually in the purchase of a radar level meter will be their working conditions and related parameters to inform the manufacturers, and manufacturers through professional knowledge to determine whether to choose high-frequency radar level meter or guide wave radar level meter or FM radar level meter. But when the actual application, there will be some errors, because some conditions are also very variable, find the problem in time to communicate to solve is the right solution.