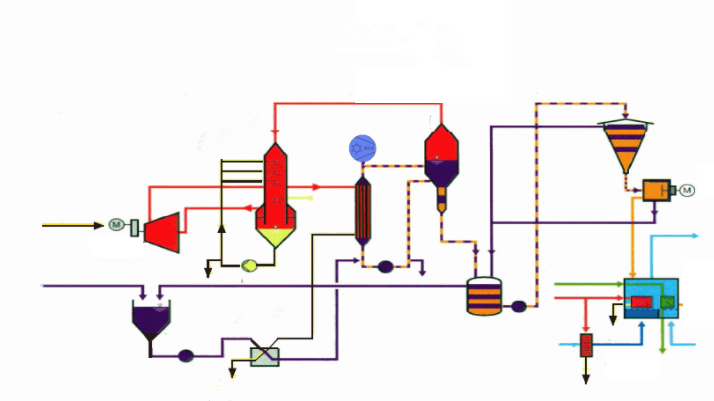

Both vacuum salt production systems and salt and nitrate co-production systems require brine as a raw material. In the vacuum salt system, the brine is evaporated and concentrated as raw material and then dried to become a finished product – salt. During the whole process, is a radar level meter used? Is there a need for a radar level meter?

To understand this problem, it is necessary to first understand an important link in the evaporation process of salt production – the level control of the evaporation tank.

During the operation of the evaporation tank, the brine medium will produce violent boiling under different conditions and is prone to crystallization and corrosion, and other characteristics. If the brine level is too low, the static pressure appears to be reduced, the brine boils in the heating tube, which will intensify the generation of salt scale, and the heating tube is easily blocked, causing production to slow down or even stop. If the brine level is too high, the circulation speed of the brine will not only slow down, the hydrostatic pressure will increase, affecting the evaporation intensity and production speed, and to a certain extent, the water quality of the condensate.

From these two aspects, level measurement is necessary and very critical in vacuum brine production systems. But why use radar level meters when another level measurement is not possible?

According to a survey, a salt plant used heavy hammer level meters, capacitance level meters, differential pressure level meters, and float level meters from 1992 to 2003. As a result, it was found that these measuring instruments, either required a large amount of maintenance or had poor measuring accuracy, and some even became stuck and blocked. Therefore, in vacuum salt systems, these are not ideal level measuring instruments. Radar level meters, on the other hand, have advantages that other level meters cannot match.

First of all, it is highly resistant to interference. A radar level meter almost can overcome the influence of corrosion, foam, and water vapor on the liquid level measurement.

Secondly, the product models are diverse and can be used in different working conditions. There are various antennas for the radar level meter, various process connections, various power connections, and even three types of housing material. To a certain extent, the person concerned can make the most suitable products according to the needs of customers and meet the needs of more people.

Finally, the measurement is accurate and stable. With the increase in frequency, the radar level meter has become more and more accurate and stable. For working conditions such as brine occasions, the accuracy of radar level meter is basically unaffected.

Radar level meters are used in vacuum salt production systems. In other areas, radar level meters are also used, but different conditions are suitable for different level meters. When choosing, choose the one most suitable for your working conditions.