The flow meter displays fast

● Whether the customer has set the parameters

● If the installation is in accordance with the requirements

● Is it within the flow range

● Is the temperature and pressure display normal, if abnormal check steps refer to 5 or 6

If the meter is connected to an external power supply or output, remove the cable and observe the operation with the battery power only

Consider the local atmospheric pressure. If the atmospheric pressure at the site is lower than the standard pressure, but the standard pressure is still used for the parameters in the instrument, the flow rate is fast. (except for adiabatic pressure changes)

Note: If the flow is fast, let the customer pay attention to the instantaneous flow rate to show that the upper limit does not exist.

Solution.

● Adjust the coefficient, which is inversely proportional to the flow rate

If the external power supply or output line interference is causing the flow rate to be fast, solve the problem by referring to 2

If there is no problem with the meter, and you cannot find the problem on-site, return to the factory to calibrate if the meter itself is fast

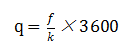

An approximate algorithm for calibration flow rate.

The f-frequency value can be seen on the secondary screen by pressing the SET key.

q — instantaneous flow rate at working conditions (m3/h)

f — frequency (HZ)

K — coefficient (times/m3)

Q — standard condition (Nm3/h)

Gauge pressure — field pipe pressure (kg)

1 — atmospheric pressure (kg)

Flow meter display too slow

● Whether the customer has moved the parameters

● Is the installation in accordance with the requirements

● Is it within the flow range

● Is the temperature and pressure display normal, if abnormal check steps refer to 5 or 6

● There are a lot of impurities on the strainer or filter at the front end, another phenomenon at this time is the pressure loss becomes bigger

● Long-term use, bearing wear and tear, return to the factory for repair

Solution:

● Adjust the coefficient, which is inversely proportional to the flow rate

● Return the instrument to the factory for testing and repair