INTRODUCTION

Liquid and gas flow meters are the two types of flowmeters. Liquids are normally measured in terms of volumetric flow rate, whereas gases are measured in terms of mass flow rate, due to the variations in properties between liquids and gases. While certain volumetric systems can track gas flow rates, totalized flow can be problematic. Mass-flow sensing technology is usually the best solution when measuring air or other gases, especially in critical applications.

Gaseous hydrochloric is produced as a byproduct of the manufacturing of the intermediate chemical MDI, which is crucial in the plastics sector.

It’s recycled and sent to the chlorine division of the Facility’s chemical plant in a 32 percent concentration. By introducing diluted acid to the HCI absorbers, the desired concentration can be achieved. The amount of HCI gas must be monitored at the absorber’s inlet in order to load them uniformly and supply the necessary amount of diluted acid.

The facility is currently unable to function without flow measurement. This has traditionally been done with a differential pressure meter due to the particular criterion for measurement dependability. Even this supposedly trustworthy measuring equipment, however, had a limited lifespan. The pressure transducer’s small tubes, in particular, proved to be extremely prone to wear. As a result, several leaks occurred. The process had to be shut down for maintenance, which took a lot of time and effort because the pipelines had to be emptied and cleaned under high pressure.

Thanks to the non-invasive electromagnetic gas flow meter, these annoyances are now a thing of the past. Small negative pressure of -20 mbar at the measurement position has no effect on the flow meter. The flow rates recorded are fed into the process control system, which subsequently regulates the amount of diluted acid injected.

UNIQUENESS OF AN ELECTROMAGNETIC FLOWMETER

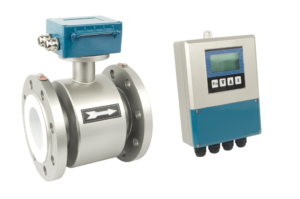

Electromagnetic flowmeters, also known as magnetic flowmeters or mag meters, are in high demand because they have fewer obstructions in the pipe, are cost-effective for very aggressive chemicals and slurries, and provide highly accurate volumetric flow measurements. Electromagnetic flowmeters come in a variety of liner materials, electrode configurations, and line diameters to suit a wide range of applications. They can also measure fluids and gases in both directions and are very good at measuring volumetric flows at both low and high flow rates.

The sensors within the electromagnetic flowmeters, which are positioned inline, measure the induced voltage caused by the passage of fluids and hostile gases through the pipe. It also features a transmitter that works in tandem with the sensor, translating the sensor’s voltage into flow measurements and then transferring the flow measurements to a control system.

FLOW AND CONCENTRATION MEASUREMENT OF AGGRESSIVE MEDIA

In the production of intermediates, fertilizers, polymers, and other specialty chemicals, sulfuric, nitric, hydrochloric, hydrofluoric, and other acids, as well as caustics, are widely used as base chemicals. As a result of the aggressive media, wetted measurement technologies are always vulnerable to corrosion, and they are prone to future failure and pipe leakage. The electromagnetic flowmeter is mounted on the outside of the pipe wall, eliminating these issues and providing the plant operator with precise and reliable mass flow rates that are also maintenance-free. Its ultrasonic process analyzers can monitor acid or caustic strength as well as provide real-time quality control.

FEATURES OF AN ELECTROMAGNETIC FLOWMETER

Electromagnetic flowmeters are distinguished from the competition by their distinctive traits or qualities, which are mostly based on their operating principles and mechanism. Because of these principles, the electromagnetic flowmeter is the most sought after by HCL processing plants globally;

- It has several electrodes that detect the density, viscosity, and matter constituents of liquids.

- It has sensors that can be attached on the go.

- Maintenance, installation, and cleanliness are simple to achieve since dealing with wastewater necessitate a flowmeter that is simple to use.

ADVANTAGES

- Flow measurement that is accurate and reliable without contacting the medium

- There is no loss of pressure, no wear and tear from the abrasive medium, and no possibility of leaks.

- Without the use of pipework, the measurement system can be installed, set up, and any necessary repairs or maintenance can be performed.

- There will be no interruptions to the process.

- Concentration regulation that is consistent and reliable

CONCLUSION

As shown above, for a plant to get accurate readings in the HCL measurements in its production process it is imperative for said plants to acquire an electromagnetic flowmeter. It is a safe way of measuring flows of the corrosive and aggressive medium as it eliminates the need for physical human intervention in the measurement process.

The electromagnetic flowmeter also has features such as a reading board, Wi-Fi access, and others that help make it give very accurate readings of the medium it is processing. It is a wise choice to use one in your plants.