INTRODUCTION

Numerous gas burners provide the requisite heat for the kiln in a quicklime production facility—which is our focus facility for this article. Every burner is connected to a natural gas circuit that is closed. Only by keeping the lime-burning process between +900…1100°C / +1652…2012°F can CO2 be freed from the limestone and the appropriate quicklime product be obtained. As a result, the customer’s ability to regulate the burning process and monitor burner performance is critical. This necessitates accurate and steady flow measurement under changing temperature and pressure circumstances.

Not until recently, the majority of quicklime production facilities have not employed any measuring devices to fix this problem. They on the other hand choose to install process instrumentation after experiencing recurrent issues with decreased burner performance owing to soot buildup. The majority of facilities required exact information on the amount of natural gas consumed in standard volume flow. Similarly, the measurement device was to offer additional information in order to continuously check the operating parameters as well as the burners’ performance. They also preferred a measurement instrument that could not only measure the flow rate but also determine other characteristics simultaneously. This device was supposed to be cost-effective and maintenance-free, as well as reliable and long-term steady.

MEDIUM NATURAL GAS

Operating density: 1.46 kg/m3;

Volume flow rate: 50 m3/h

Pressure: 17.400 psi / 1.2 bar

Temperature: 20°C (68°F)

Viscosity 0.01 mPas

THE SOLUTION

It was feasible to take precise measurements of the natural gas volumes supplied to the burners that heat the lime kiln using the Vortex flowmeters. The measuring instruments for this application include not only flow measurement, but also temperature and pressure measurement. Unlike other traditional flowmeters, the Vortex flowmeter may output the flow as a standard volume flow that is pressure and temperature corrected.

BENEFITS TO THE USER

The Vortex flowmeter allows the facilities to provide gas to their burners in such a way that the temperature within the kiln is always within an ideal range for the lime-burning process. The all-in-one gadget compensates for changing process conditions. When compared to Vortex flowmeters with external temperature and pressure sensors and an additional computer unit, the customer was able to save up to 45 percent on installation expenses by measuring flow, pressure, and temperature in one device. Because all measured values are taken at a single measurement point, the system’s overall accuracy is automatically boosted.

The Vortex flowmeter’s multi-parameter measurement allows for more than just determining natural gas consumption. The measuring equipment can also be used to determine the maintenance needs of gas burners, resulting in increased system availability. The pressure in the pipelines rises every time the burner nozzles start soothing, which the Vortex flowmeter instrument can accurately detect. The Vortex flowmeter also indicates when predictive maintenance of the burners should be performed in this manner. This adds value to the quicklime producer by preventing unplanned and costly process disruptions as well as gradually lowering burner performance.

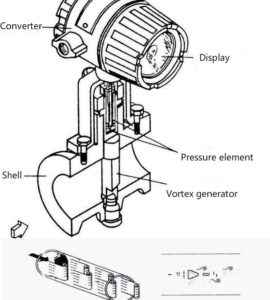

THE VORTEX FLOWMETER

The American Petroleum Institute published guidelines for custody transfer of natural gas in 2007, with modifications in 2010. Vortex meters are a latecomer to API approval for custody transfer of natural gas. Vortex meters have struggled to catch up to ultrasonic, differential pressure, and turbine meters due to this late approval. As a result, vortex meters have been unable to break into the natural gas custody transfer industry. The meters are largely utilized in industrial markets, with very little natural gas usage custody transfer.

PROS OF PURCHASING THE VORTEX FLOWMETER

The DP flowmeter is the only other meter that is as adaptable as the vortex flowmeter. The vortex meter can accurately measure gas, liquid, and steam flow, but it does so with more precision and less pressure drop than DP flow meters. Vortex meters can withstand the high temperatures associated with steam flow measurement. Multivariable vortex meters with mass flow measurement capabilities are available, and the meters have no mechanical components. As previously indicated, the meter is allowed for use in custody transfer petitions.

While it has been approved for natural gas fiscal billing, its late arrival into the market has slowed market penetration and product acceptability. Due of its bluff body, there may be some pressure decrease. The most significant challenge with vortex meters is that noise from pipe vibrations or other disturbances degrades the meter’s accuracy.

FEATURES OF THE VORTEX FLOWMETER

- There are no mechanical moving parts, they are not prone to corrosion, they are stable and trustworthy, they have a long-life span, and they do not require any particular care.

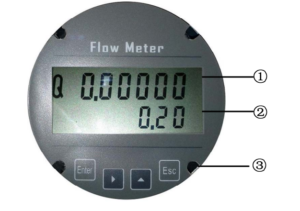

- 16-bit computer chip with great integration, small size, good performance, and a wide range of applications;

- The intelligent flowmeter combines a flow probe, a microprocessor, a pressure and temperature sensor, and uses a built-in combination to make the structure more compact, allowing it to directly measure the flow, pressure, and temperature of a fluid while automatically compensating for real-time tracking and compression factor correction.

- To considerably increase the signal strength, the sensor uses double probe detection technology, novel sensor processing technology, and a practical installation method. As a result, the sensor can properly detect the signal and reduce the interference produced by pipeline vibration.

- Adopt the most advanced intelligent anti-seismic technology in the country, which effectively suppresses the signal created by vibration and pressure fluctuations.