INTRODUCTION

The use of microorganisms and their products to accelerate the separation of metals from ores and waste materials is referred to as biomining. If you’ve read articles about biomining, you’ve probably come across two terms: ‘bioleaching’ and ‘bio-oxidation.’ You most likely assumed they meant the same thing and could be interchanged. Not at all! The two words are slightly different in terms of their biomining applications, but the essential concepts are the same. Gold biomining is an excellent illustration of how to fully comprehend these two phrases.

Let’s proceed to what you are aware of- that biomining is the blanket word for all biotechnological techniques that use microorganisms to remove metals from ores. Bio-oxidation is a biomining technique that utilizes microorganisms to pre-treat ore by disintegrating minerals that obstruct the leaching of your desired metal(s). Bioleaching is a biomining technique that uses microorganisms to liquefy your desired metal(s) [1]. As a result, you can also see that the difference is in what happens to your precious metal(s).

The right term to use is ‘bioleaching’ if your metal of interest is likely to be decomposed in solution by microbes. If microbes are employed to destroy impurities that obstruct your metal of interest, the term ‘bio-oxidation’ is fitting. In a subsequent operation, this metal of importance can be dissolved. Biomining of gold applies both bio-oxidation and bioleaching methods.

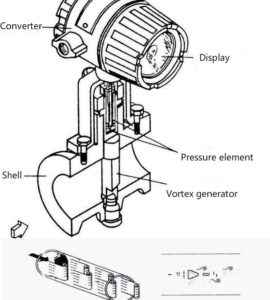

HOW DO VORTEX FLOWMETERS MEASURE AIRFLOW

The frequency of vortices formed by a “bluff body” or “shedder bar” is measured by vortex meters, which are simply frequency meters.

Vortices will only form at a specific velocity (Re-number); hence vortex meters will have an elevated zero called the “cut-off” point. The meter’s output will be cut to zero before the velocity reaches nil. Some vortex meters may give an output signal over a specific back-flow (cut-off point), resulting in an erroneous interpretation.

Vortex meters, like orifice meters, measure actual volume flow. Because certain meters are intrusive, such as orifice meters, the pressure will drop as the flow increases, resulting in a permanent loss. As a result, liquids nearing their boiling point may cause cavitation as the pressure across the meter falls below the liquid’s vapor pressure.

When the pressure rises over the vapor pressure, the bubbles obstruct cavitation, causing the meter to fail, which should be avoided at all costs.

When a stretched wire vibrates in airflow, the frequency is related to the air velocity, according to Strouhal. “Vortex shedding” is the term for the occurrence, and the vortex train is known as “Karman’s Vortex street.”

The frequency of vortex shedding is a pin-point linear function of fluid velocity, and the shape and face breadth of the bluff body has an impact on it. Because the width of the obstruction and the inner diameter of the pipe will be more or less constant, the frequency is specified by the expression.

AIRFLOW MEASUREMENTS REQUIREMENTS

The sulphide treatment plant has to be modified in this context. This will comprise a bio-oxidation plant that consists of numerous tank reactors with agitators where sulfphides in mined ore are oxidized. Bio-oxidation is a step in the carbon-in-leach (CIL) process that prepares the material for cyanidation. This is due to the fact that gold ore is naturally refractory and encased in sulphide minerals. It must first be made cyanide-leaching accessible. This is accomplished through bio-oxidation, in which bacteria oxidize insoluble metal sulphides and convert them to water-soluble sulphates.

Ideal circumstances for the bacteria must constantly exist for the intended bioreaction to occur. Temperature, pH, and air supply (oxygen and carbon dioxide) are the most important control parameters for achieving the best oxidation of sulphide gold ores feasible. The mine operator required strong and dependable flow instrumentation that was also cost-effective in order to continuously check the air supply.

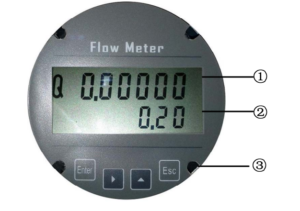

Vortex flowmeters should be installed for optimal performance. The measurement gadget is also available in a remote version with field housing. The flow sensors might be positioned up to 50 m / 164 ft away from the remote signal converters. Readings from difficult-to-reach installations can be simply taken where they are needed in this manner. You could utilize pipes with big nominal diameters to install them. Even with the supplied air pipe diameters, this ensures a considerable measurement span.

USER BENEFITS

The Vortex flow meter assists the mine operator in maintaining a high level of Sulphur oxidation in the ore. The supply of air is ensured, and bio-oxidation can be carried out in a controlled manner. This creates ideal circumstances for greatly enhancing gold extraction while lowering cyanide consumption in the succeeding carbon-in-leach circuit.

ADVANTAGE OF THE VORTEX FLOWMETER

Vortex flow meters have a number of advantages for flow measurement, including quick installation without the use of impulse lines, no moving parts to maintain or repair, lower leak possibility, and a large flow turndown range. Vortex meters consume extremely little power, making them ideal for usage in distant locations.

Vortex meters are also unique in that they can handle liquids, gases, steam, and corrosive liquids and gases. High process pressures and temperatures are also no match for vortex flowmeters.