Installation of Float Flowmeter

- Float flowmeter should be installed in a place where the environment is lower than 60℃ to prevent the meter from being directly exposed to rain and sun, and in a location that is convenient for installation, operation, adjustment, and safety.

- The float flowmeter must be installed vertically on a vibration-free pipe, and there should be no obvious tilt. If there is a tilt, it should be less than 2°. According to preliminary calculations, if the flowmeter is tilted 10°, an additional error of 0.8% will occur.

- In order to facilitate maintenance. When replacing the flow meter and cleaning the measuring pipeline, there should be enough space on-site, and necessary valves should be installed upstream and downstream of the flow meter. Under normal circumstances, the upstream valve should be equipped with a fully open valve, followed by a flow regulating valve, and a bypass pipeline should be installed at the position of the flowmeter, and a bypass valve should be installed.

- For dirty fluids, a filter should be installed upstream of the flowmeter. If the measured medium contains magnetic substances, a magnetic filter should be installed upstream of the flowmeter. When necessary, a washing pipe should be installed to regularly flush the flowmeter and measuring pipe. Otherwise, the cleanliness of the float will affect the measured value of the flowmeter.

- When installing a flowmeter on a pipeline that may cause fluid backflow, to avoid damage to the flowmeter due to fluid backflow or water hammer, a check valve should be installed downstream of the flowmeter.

- If the float of the float flowmeter fluctuates greatly and is unstable, one of the reasons may be that the fluid itself is pulsating, and the other reason is the oscillation of the flowmeter itself. If the former is the cause, the piping system should be improved, if the latter is the cause It should be eliminated in response to specific problems.

- When moving the float flowmeter, the float and pointer should be fixed to avoid the pointer and other parts from being impacted and damaged when the float moves up and down.

- When disassembling the metal tube flowmeter, pay attention to the exposed part of the float connecting rod. The user can connect a straight pipe section that protects the exposed part of the connecting rod, and it can be disassembled and assembled at the same time as the flowmeter during installation.

- For measuring the medium that is easy to vaporize, crystallize and solidify, the flowmeter can choose the metal tube float flowmeter with jacket. For the flowmeter with a jacket, the metal pipe and the stainless steel joint on the jacket can be welded.

- For the electric remote transmission metal tube float flowmeter, the power supply and output are connected to the outside with a four-core plug. After the installation and connection are completed, the power supply can be switched on and put into use after checking that it is correct.

Use of float flowmeter

- After the float flowmeter is correctly installed on the pipeline, slowly open the upstream valve to fully open when using it, and then adjust the flow with the downstream flow regulating valve. When the flow meter is out of use, slowly close the fully open valve, and then close the flow control valve.

- When using, it is necessary to prevent sudden changes in the pressure of the fluid to be measured and to prevent the float from damaging the glass cone.

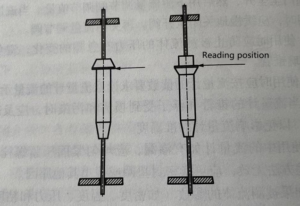

- When in use, the flow rate indication of the flow meter should be read according to the reading requirements of the flow meter.

- When the cone and float of the flow meter are damaged or contaminated, they should be replaced and cleaned in time to avoid affecting the accuracy of the flow meter

- If there is leakage in the flowmeter in use, the compression bolts or nuts should be evenly tightened. If the above method is invalid, the sealing gasket should be replaced or other reasons should be found.

- If the parameters of the measured fluid (such as density, temperature, pressure, viscosity, etc.) are different from the state when the flowmeter is scaled, the scale conversion of the flowmeter must be carried out.

- When the metal tube float flowmeter is used, when the shell has a ground terminal, it must be reliably grounded during installation and use.

- When the flowmeter is used as an intrinsically safe device, it should be used together with the associated equipment safety barrier. The installation of the flowmeter and the cable wiring environment should eliminate the influence of external electromagnetic interference as much as possible so that the distribution parameters of the cable are controlled within the parameters specified by the safety barrier. The installation limit of the safety barrier must follow the instruction manual of the safety barrier.

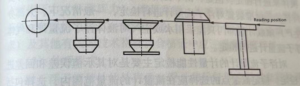

The reading position of the float flowmeter

- Figure 8-4 shows the reading position of the glass cone float flowmeter

2. Figure 8-5 shows the reading position of the metal tube float flowmeter