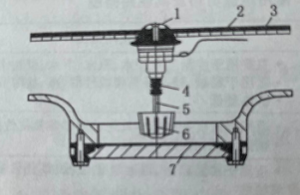

When measuring sewage, slurry, and other media, the inner wall of the pipe and the surface of the electrode are prone to fouling and adhesions. When the conductivity of the fouling substance is different from that of the measured medium, measurement errors will be brought about. The adhesion of sludge and oil to the electrode will also cause the instrument output swings and drifts. Therefore, maintenance treatment of the electrode is required in some cases. For example, cleaning the electrode and replacing the electrode. Figure 3-28 is a structure for replacing the electrode.

The commonly used methods for electrode cleaning are as follows:

(1) Electrochemical method

The gold surface electrode has an electrochemical phenomenon in the electrolyte fluid. According to the electrochemical principle, there is an interface electric field between the electrode and the fluid, and the interface electric field between the electrode and the fluid is caused by the electric double layer between the electrode/fluid phase. Research on the electric field at the interface between the electrode and the fluid

The research found that the molecules, atoms, or ions of the substances are in the boundary and have enriched or poor adsorption, and found that most inorganic anions are surface-active substances with typical ion adsorption laws, while the surface activity of inorganic cations is very small. Therefore, electrochemical cleaning

Only consider the case of anion adsorption. The adsorption of anions is closely related to the electrode potential. The adsorption mainly occurs in the potential range that is more positive than the zero charge potential, that is, on the electrode surface with a different charge. On the surface of the electrode with the same charge, when the residual charge density is slightly larger

When the electrostatic repulsion force is greater than the adsorption force, the anions are quickly desorbed. This is the principle of electrochemical cleaning.

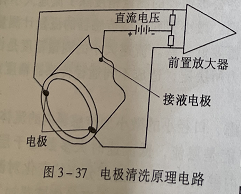

Figure 3-37 is a schematic diagram of electrochemical cleaning. Some companies add the voltage drop of two forward diodes to the signal return on the road, a negative voltage of about 1.2~1.4V is applied to the two electrodes in the form of a common mode. Because the added on the two electrodes

The voltage is a negative DC common-mode voltage, which will not cause the amplifier to saturate. DC common-mode voltage is superimposed on the tiny alternating flow signal above, the DC is isolated by the capacitor, and the common-mode voltage is suppressed by the preamplifier. The DC common-mode voltage will not affect the flow measurement. The DC negative voltage applied to the electrode forms a negative electric field that can repel the substances attached to the electrode and achieve the purpose of cleaning the electrode. This method can effectively, automatically, and continuously clean the electrodes in AC excitation. But for low-frequency rectangular wave excitation, due to the high polarization voltage amplitude, the effect may not be very good, so it is rarely seen recently.

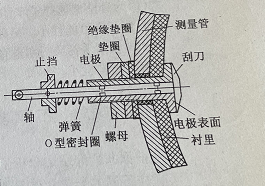

(2) Mechanical removal method

The mechanical removal method is to realize the electrode by installing a special mechanical structure on the electrode clear. There are currently two forms:

One is to use a mechanical scraper. A scraper with a thin shaft is made of stainless steel, and the scraper is drawn out through a hollow electrode. A mechanical seal is used between the thin shaft and the hollow electrode to prevent the medium from flowing out (see Figure 3-38), thus forming a mechanical scraper. When the thin shaft is rotated from the outside, the scraper rotates against the surface of the electrode end to scrape off the dirt. This kind of scraper can be manually or automatically scraped by a motor-driven thin shaft.

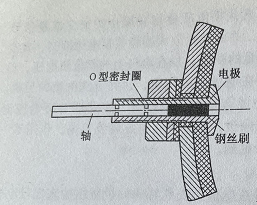

The other is to install a wire brush for removing dirt in the tubular electrode, and the shaft is wrapped in a sealed “O” ring to

Prevent fluid leakage (see Figure 3-39). This cleaning device requires someone to often pull the wire brush to clean the electrode.

(3) Ultrasonic cleaning method

Apply the ultrasonic voltage of 45~65kHz generated by the ultrasonic generator to the electrode, so that the energy of the ultrasonic is concentrated on the contact surface of the electrode and the medium, so as to use the energy of the ultrasonic to break the dirt and achieve the purpose of cleaning.

(4) Electric breakdown method

This method uses alternating current (50Hz or 60Hz) high voltage to be periodically added between the electrode and the medium, generally 30~100V. As the electrode is attached, its surface contact resistance becomes larger, and the applied voltage is almost concentrated on the attachment. High voltage will hit the attachment.

Wear it, and then be washed away by the fluid. From the perspective of safety, the use of electrical breakdown method must be to clean the AC (50Hz or 60Hz) high voltage directly on the sensor signal output terminal when the flowmeter interrupts the measurement, the signal line between the sensor and the converter is disconnected, or the power fails.

(5) Increasing the average flow rate in the measuring tube and using a pointed small-area electrode to measure the medium that is prone to fouling and adhesion, usually, a sensor smaller than the process tube diameter can be selected to increase the flow rate. Experience has shown that the average flow velocity in the pipe is higher than 2m/s, and the possibility of precipitation adhesion is generally small. It is also used to increase the flow velocity 3~5m/s (depending on the situation of the attached person) to flush the adhesion layer instantly. The electrode head protrudes into a pointed shape and is subject to high fluid scouring force (because the tube wall-flow rate is equal to zero, the tip leaves the tube wall boundary layer and enters the flow rate layer), so the possibility of adhesion pollution is small. In addition, since the small-area electrode itself has a large signal internal resistance, the influence of the change of the signal internal resistance caused by the electrode adhesion and contamination is small, so the impact on the meter measurement is also small.