How they work

Rotameter is a word said to have been coined in Germany early in this century, to denote what would otherwise have to be called an “a variable-aperture”(or variable area)flow rate meter employing a vertical tube and a “float”-hence the rapid worldwide acceptance of the name, which was subsequently adopted by a British company making this type of meter.

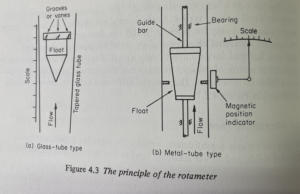

In the simplest type of rotameter, the body is a tapered transparent tube of glass or plastic with a scale engraved upon it, as shown schematically in Figure 4.3a. Inside the tube is a small solid body with a circular cross-section; this is known as a “float”, although “sinker” would be a more accurate description since it is always denser than the fluid being metered.

When there is no flow the float rests at the bottom of the tube. Flow causes it to lift off its seat, so as to maintain the pressure drop across the float in equilibrium with the effects of buoyancy and gravity upon it. Since the immersed weight of the float is a constant for any given fluid, the pressure drop must also remain constant. Consequently, as the flow increases the float will rise in the tapered tube to provide a wider annular aperture for the fluid to pass through. The height of the float is thus an indication of the flow rate passing, and the scale on the transparent tube can be graduated directly in units of the flow rate.

It is essential for the float to be maintained coaxial with the tube. This is normally achieved in the transparent-tube type of rotameter by the presence of inclined vanes on the float. The action of flow on these vanes imparts rotation to the float which provides the necessary stabilizing and centering effect. It is this visible rotation that gave rise to the name “rotameter”, of course.

The broadly similar device shown in Figure 4.3b is also generally called a rotameter, even though it does not usually rotate. In this case, the tube is made of metal and is not tapered, and the variable aperture is provided by the movement of a tapered float inside a fixed orifice. The position of the float is sensed by an electromagnetic device on the outside of the tube, and its reading is normally displayed on the dial, which may be either attached to the tube or remote from it.

On the transparent-tube type, the readout may be described as “more or less linear”, since the vertical movement of the float is usually not too far from being directly proportional to the flow rate. The metal-tube type allows scope for more subtle engineering, and these are usually designed to give a truly linear characteristic. Both types have a rangeability of about 10:1.

Advantages and disadvantages of the transparent-tube type

It is probably the handiest, cheapest type of flow rate meter on the market. Its construction is so simple that there is very little that can go wrong with it unless it is maltreated or used with unsuitable fluids; consequently, it will usually maintain its original performance for many years.

Against this must be set the fact that the performance of the cheaper versions is never spectacular. To keep their price down they are normally given only a rudimentary form of calibration, and their accuracy is then not better than ±2 or 3% at the full-scale reading. However, although they are not common, high precision glass rotameters can also be obtained at a price with an accuracy of about ±0.5%.

The rotameter has quite a high head loss, and because it can only be used in a vertical position it demands some contorted pipework if it is to be installed in a horizontal pipe, which causes an additional head loss. Its readings are affected by changes in viscosity or density, so that, for example, a meter intended for use with water will be seriously in error if used with gasoline. It takes up rather a lot of space, and although models with a rather higher capacity are obtainable, it is rarely used for flow rates above 1 liter of water per second or a few tens of liters of air per second.

Advantages and disadvantages of the metal-tube type

Because there no risk of the tube bursting, the metal-tube rotameter can be used over a very wide range of temperatures and pressures, and large meters that will handle much higher flow rates than the transparent-tube type are practicable. If necessary it can be made from materials that will withstand acids and highly corrosive fluids, and designs with “straight-through” connections are available which will handle viscous liquids and suspensions of solids. It can be supplied with either an electrical or pneumatic readout.

Needless to say, these advantages have to be paid for, and the metal-tube rotameter generally costs much more than the glass-tube type. It also shares the latter’s disadvantages of being rather bulky, of having a high head loss, and of being sensitive to changes in viscosity and density.

When to use them

The inexpensive type of glass-tube or plastic-tube rotameter is often the most economical flowmeter for use where moderate or low flow rates of water, air, or low-viscosity fuels have to be metered to within a few percent. It is widely used both as a “plumbed-in” flow meter in process plants and as a portable flow meter for odd jobs in laboratories and test houses. The more costly high-precision glass-tube rotameter is useful as a reference meter.

The metal-tube rotameter has an entirely different sphere of usefulness. Its forte is handling awkward fluids which cause trouble with many other types of flowmeter, including viscous suspensions of solids in liquids. Although it can also be used with such simple fluids as air and water, it is unlikely to be the most cost-effective type of meter in such circumstances.