Almost every commercial industry produces wastewater. For many, it is important to monitor the amount of wastewater being produced in order to comply with environmental regulations and/or disposal fees. Measuring the effluent—or discharge flow–is problematic. But as you will see below, there is a solution.

Types of Industries that Produce Wastewater

As previously mentioned, wastewater is a by-product of almost every commercial manufacturing enterprise. However, some types of industries are particularly heavy producers of wastewater. Such industries include (but are not limited to):

- Mining: Dealing with the tailings—or leftover rock—represents a major wastewater stream.

- Oil and Gas Drilling: The materials that come from the drill hole are often highly contaminated and are definitely considered wastewater.

- Chemical Companies and Refineries: While environmental regulations have cleaned up chemical companies and refineries considerably, the very nature of their business necessitates that they will produce wastewater streams.

- Wastewater Treatment Plants: It may seem counterintuitive to think that wastewater treatment plants produce wastewater, but the contaminants stripped out from the influent—incoming stream—must go somewhere; therefore, this too requires monitoring.

- Food Processing: Both vegetable and animal processing facilities have serious wastewater considerations. Pesticides from vegetables are washed off at processing facilities, and the waste from slaughterhouses represents a wastewater discharge.

The Solution for Measurement of Wastewater

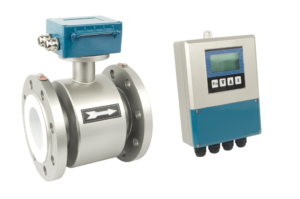

The best and most accurate measuring solution for industries that produce wastewater is an electromagnetic flowmeter. Electromagnetic flowmeters—or “mag meters” as they are often called—are the measuring tool of choice amongst many of the aforementioned leading industries.

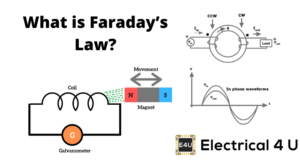

The way that mag meters work is that they rely on Faraday’s Law of Electromagnetic Flow Induction. In short, as fluid or slurry flows through a pipe in which there is a magnetic field, the conductive particles change the voltage in the field. The mag meter detects these changes and uses a microprocessor to compute the flow—and does so with amazing accuracy. However, the most important thing is not so much understanding how they work, but trusting that they do work.

With a base in solid physics, electromagnetic flowmeters are industry-proven and are used in processes around the globe as a trusted device in the measurement of flow. This is particularly the case when hard-to-measure materials require precise measurement.

- What does an electromagnetic flowmeter consist of?

The simplicity of design is what makes mag meters the flow-detection device of choice. Sensors on the pipe measure the flow and send a signal to a converter which relays the flow rate to operators. It really is that simple. Mag meters are extremely reliable and work consistently without the need for constant recalibration.

- What are the features and benefits of an electromagnetic flowmeter?

- They can be installed on very large pipes—up to 800mm.

- The flow measurement is not affected by changes in:

- Fluid density

- Viscosity

- Temperature

- Pressure

- Conductivity

- There is no obstruction component in the pipe that can cause pressure/flow loss.

- Mag meters are low maintenance.

- They are designed for superior corrosion and wear resistance.

- They can utilize a wide range of power supplies and have excellent Electromagnetic Interference (EMI) resistance.

- Mag meters use super-fast microprocessors that can self-test and self-diagnose.

- What are the specific applications of mag meters in wastewater measurement?

Electromagnetic flowmeters can be used in both aboveground and underground industrial piping installations. Furthermore, they can be employed in open channel situations.

The types of electromagnetic flowmeters that have excellent wastewater applications include:

- Remote

- Compact

- Insertion

So, when your wastewater-producing process demands a high degree of precision, consider an electromagnetic flowmeter to solve your flow measurement problem.

For more information on electromagnetic flowmeters, click here.