For those in the industrial level measurement field, selecting the 80G radar level meter can often feel overwhelming. Manufacturers provide a lot of technical details—such as range, blind spots, and explosion-proof ratings—and it can be confusing. Choosing a high-end model could lead to concerns about wasting money, while a cheaper model might not meet the requirements, especially for high-temperature or corrosive environments. However, selecting the right 80G radar level meter isn’t as complicated as it seems. The key is to understand your specific needs and match them with the features of the product. In this guide, we’ll cover everything from preparation to common pitfalls, so even beginners can make the right choice.

First, it’s important to understand that the 80G radar level meter is not a “one-size-fits-all” solution. While its higher frequency (80GHz) offers better accuracy and stronger anti-interference compared to traditional 24G radar meters, choosing the wrong model will still waste money. So, before diving into the technical details, ask yourself three simple questions: What substance are you measuring? In what environment will you measure it? Are there any special requirements for the site? If you can answer these three questions, you’re already halfway to making the right choice.

1. Preliminary Work: Understand Your Site’s Conditions

Many people jump straight into asking, “How much does the 80G radar cost?” This is a common mistake. Without understanding the site conditions, manufacturers will either quote a high price or recommend a model that doesn’t suit your needs. To make an informed choice, gather the following information. Whether you’re contacting a manufacturer or comparing models yourself, this will help you make a more targeted decision.

1.1 Measuring Medium

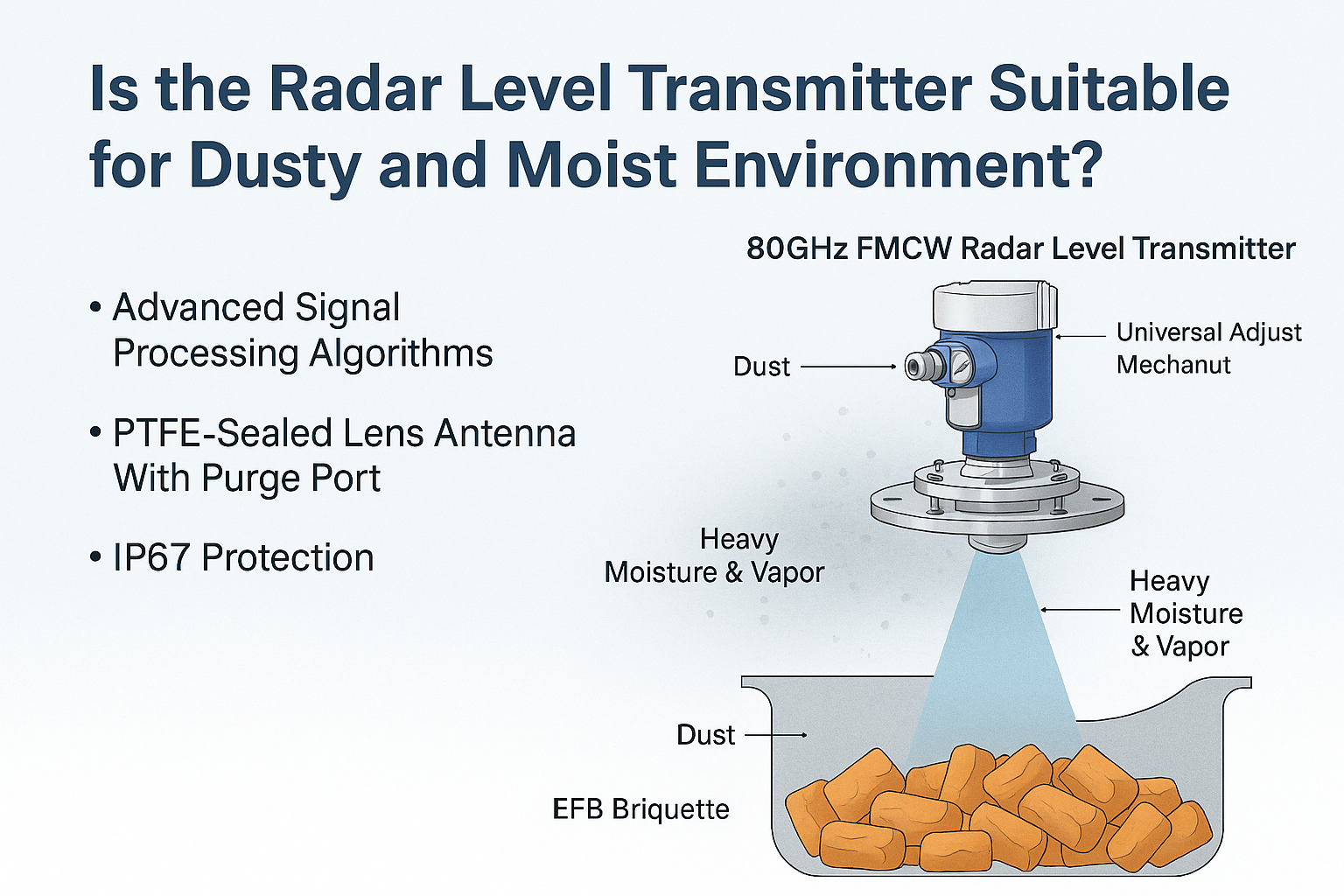

This is the core of the selection process. Different mediums have vastly different requirements for radar level meters. You need to know: Is it a liquid or a solid? If it’s a liquid, is it low-viscosity like water, or thick and viscous like oil or asphalt? Is it volatile? Will it crystallize or stick to the sensor? For example, when measuring hydrochloric acid in a chemical workshop, you need to consider corrosion resistance, and for measuring powdery materials like cement, dust interference with the antenna should be considered.

1.2 Working Conditions

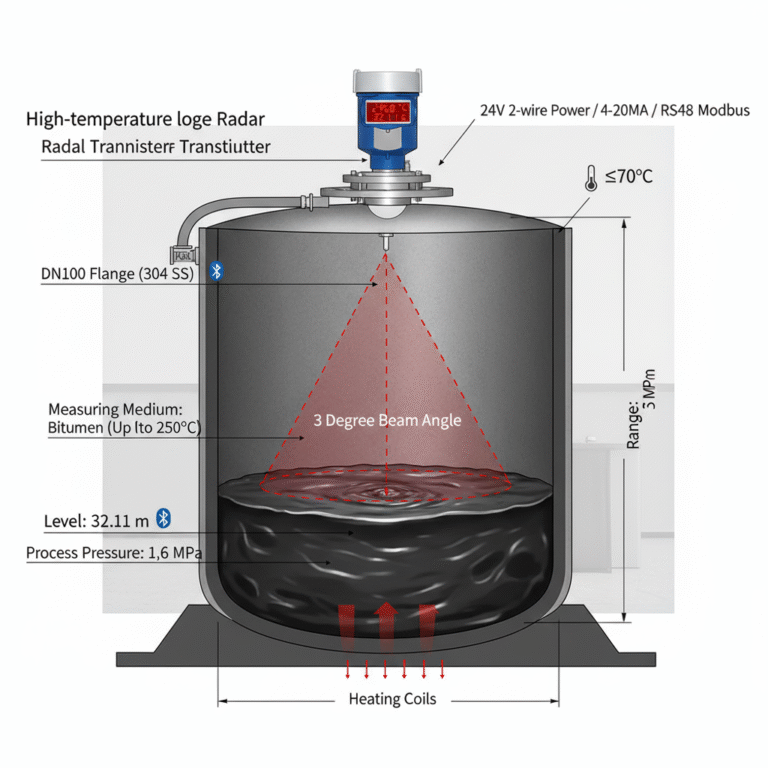

Several key factors need to be noted here: the tank height (which determines the range), whether the tank is under normal or pressurized conditions (which affects explosion-proof rating and sealing performance), and the working temperature (for high-temperature environments, a high-temperature resistant material is necessary). It’s also crucial to note any potential interference sources (such as large motors or inverters, which can affect signal stability). For example, in power plant desulfurization towers, which have high temperatures and corrosive environments, a standard radar won’t work. You’ll need one with anti-corrosion coatings and heat-resistant features.

1.3 User Requirements

Do you need precise level control, or just general monitoring? Will data need to be sent to the control room? Do you have specific power supply conditions (such as 24V DC or 220V AC)? Are there space constraints for installation (such as a small tank opening, which would require a compact antenna)? These seemingly trivial requirements directly influence the model selection— for instance, if remote monitoring is needed, you’ll need a model with 4G or RS485 communication; if space is limited, avoid large parabolic antennas.

2. Key Parameters to Focus on: Don’t Get Intimidated by Technical Jargon

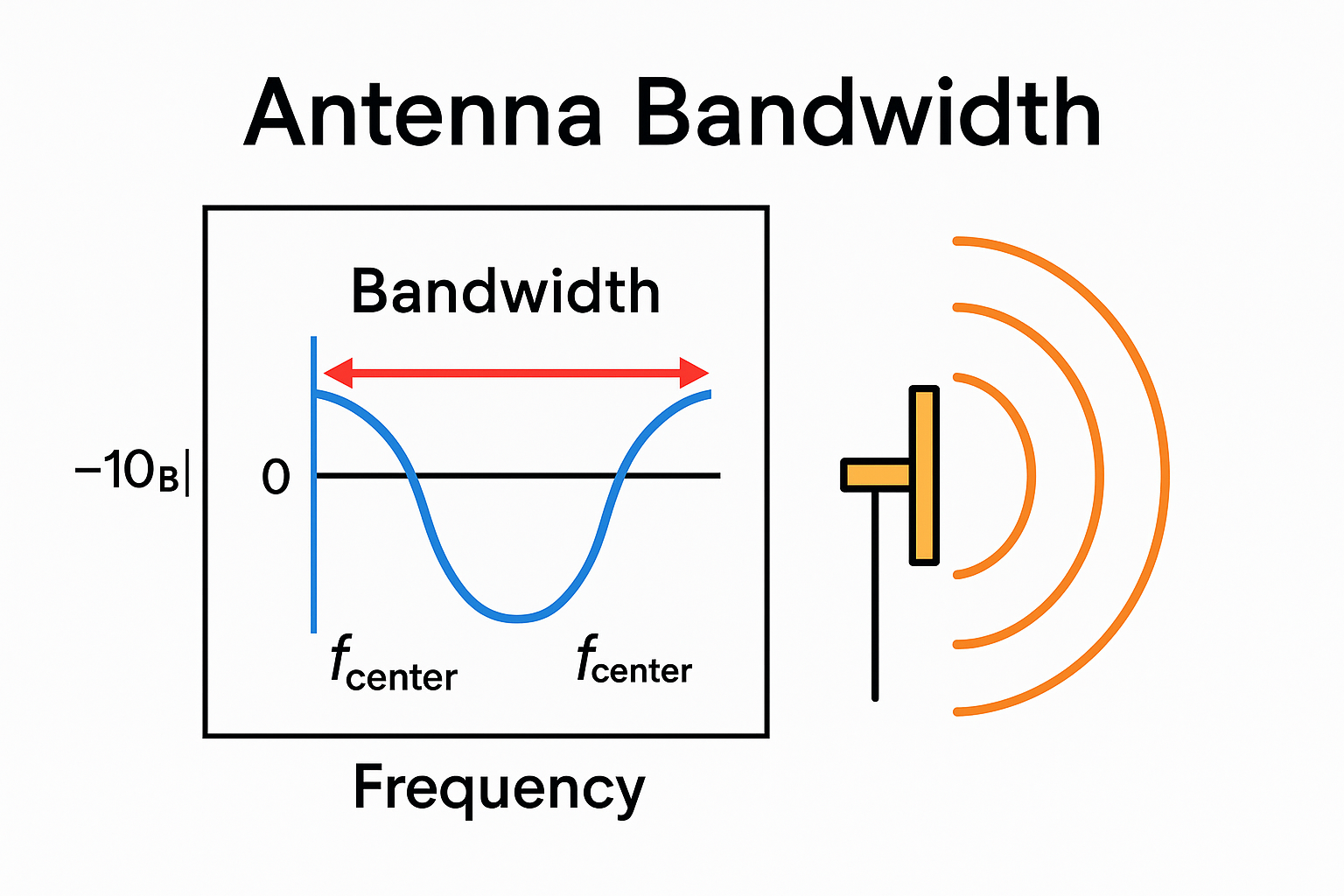

When you receive the manufacturer’s specifications, you don’t need to focus on all the data. Instead, focus on the following core parameters, while using the others for reference. Let’s break them down in simple terms.

2.1 Range

The range refers to the maximum height the radar level meter can measure. The rule of thumb is to “leave some room, but avoid wasting money.” For example, if your tank height is 15 meters and the maximum liquid level is 12 meters, a radar with a 15-20 meter range will suffice. There’s no need to opt for one with a 50-meter range, which will be more expensive and may reduce measurement accuracy. Be aware that some manufacturers report theoretical “maximum ranges,” so don’t forget to subtract the blind spot from the actual usable range (for example, if the range is 20 meters and the blind spot is 0.3 meters, the actual measurable range is 0.3 to 20 meters).

2.2 Accuracy

One of the key advantages of 80G radar is its high accuracy, typically within ±1mm, which is especially important in industries like chemicals and oil where precise level measurement is critical. However, accuracy isn’t always the highest priority. If you’re measuring a water tank, a ±5mm accuracy might be enough. But for measuring costly chemicals, even a 1mm deviation could cause significant losses, in which case high accuracy is necessary. Additionally, accuracy is affected by range— the larger the range, the more potential for slight inaccuracies, so confirm actual accuracy with the manufacturer based on your operating conditions.

2.3 Blind Spot

The blind spot refers to the area below the radar antenna that cannot be measured accurately. The smaller the blind spot, the better, right? Not necessarily—it depends on your tank. For small tanks where the medium often reaches near the top, you’ll need a smaller blind spot (e.g., 0.2-0.3 meters). For large tanks, a larger blind spot may not matter much. Here’s a tip: If your tank height is close to the radar’s measurement range, make sure to account for the blind spot to avoid “missing the highest liquid level.”

2.4 Antenna Type and Material

This is a crucial step in choosing the radar’s ability to adapt to your medium and working conditions. Currently, 80G radar antennas generally fall into three types: horn antennas, parabolic antennas, and rod antennas. Horn antennas are suitable for most liquids and solids with little dust; they are moderately priced. Parabolic antennas have better dust resistance, making them ideal for cement or fly ash silos. Rod antennas are compact and are best suited for narrow installation spaces, like small-diameter storage tanks.

Material choice is also vital. For common media, 304 stainless steel is fine. But for highly corrosive substances like hydrochloric acid or sulfuric acid, PTFE (Teflon) or Hastelloy materials are necessary. For the food industry, you’ll need materials that meet 3A sanitary standards to avoid contamination. One customer overlooked this and used a regular stainless steel antenna to measure hydrochloric acid, resulting in corrosion within a month—causing production delays and the need for costly replacements.

2.5 Explosion-proof and Protection Ratings

These are safety concerns and cannot be taken lightly. In places like chemical plants or gas stations, where flammable gases are present, explosion-proof models with at least Ex d IIB T4 Gb ratings are essential. In more hazardous environments, such as coal mines, choose explosion-proof models specific to those conditions. For protection ratings, check whether the site is exposed to water or dust. Generally, an IP67 rating is sufficient, but if the equipment is outdoors or frequently exposed to rain, opt for IP68 to prevent water damage.

2.6 Communication Methods

Choose according to your monitoring needs. If you only need local display, opt for models with local readout. If you need to transmit data to the control room, go for models with communication capabilities. Common communication options include RS485 (for connecting to PLC or DCS systems) and 4-20mA analog signals. Models with 4G or NB-IoT are also available for remote locations without wired networks. Make sure the communication method is compatible with your central control system to avoid connection issues later.

3. How to Choose for Different Applications: Tailored Solutions

It’s not enough to just look at parameters. The working conditions in various industries differ significantly, so let’s look at specific selection scenarios for common applications.

3.1 Chemical Industry — Corrosive and High-Temperature Environments

For measuring acid tanks (e.g., formic acid, acetic acid) at temperatures around 80°C and pressures of 0.3MPa, focus on “corrosion resistance, high temperature, and explosion-proof features.” Choose a PTFE-coated horn antenna with Hastelloy material, explosion-proof rating of Ex d IIB T4 Gb, and protection rating of IP67. The range should match the tank height (e.g., 15 meters for a 10-meter tank, with a 15-meter range). For communication, RS485 is recommended for integration with the central control system.

3.2 Oil Industry — Large Storage Tanks and Viscous Mediums

For crude oil storage tanks, which have high viscosity and potential for material buildup, with a tank height of 20 meters under normal pressure, focus on “material buildup interference and large range.” Choose a large-diameter horn antenna to minimize material buildup, with an accuracy of ±1mm to meet measurement requirements for oil. Set the range to 25 meters, subtracting the blind spot. For explosion-proof requirements, Ex d IIA T3 Gb is sufficient, and for outdoor tanks, opt for a sunshade and rain cover.

3.3 Food Industry — Sanitary and Easy-Cleaning Requirements

For measuring juice storage tanks with a temperature of 50°C, focus on “sanitary materials and ease of cleaning.” Choose a rod-type or small-diameter horn antenna, with a smooth surface and 316L stainless steel material that meets food-grade standards. The protection rating should be IP68 to prevent water ingress during cleaning. Since it is a non-corrosive, normal pressure environment, the explosion-proof rating can be lower—an intrinsically safe version will suffice.

3.4 Power Plant Desulfurization Tower — High Temperature, High Humidity, Corrosive Environments

In desulfurization towers with a temperature of 120°C, strong corrosive slurry, and high dust levels, select a “dust-resistant, high-temperature, and corrosion-resistant model.” Choose a parabolic antenna made of PTFE and Hastelloy, with an explosion-proof rating of Ex d IIB T5 Gb (T5 for higher temperature tolerance), and a protection rating of IP68. The range should match the tower height (e.g., 20 meters for a 15-meter tower). For high-interference environments, select a model with signal amplification to ensure stable measurement.

4. Pitfalls to Avoid: What to Watch Out For

Here are some common mistakes beginners make, so you can avoid them:

4.1 Only Looking at Price, Not Credentials

Some low-priced 80G radar models from smaller manufacturers may seem attractive, but be wary. The key component, the 80GHz radar chip, is expensive. If the price is too low, it could indicate poor-quality chips or subpar manufacturing—resulting in reduced accuracy and stability. Always check the manufacturer’s credentials, certifications (such as explosion-proof or ISO), and industry application experience.

4.2 Ignoring Installation Conditions

Many buyers realize after selecting a model that the tank opening is too small to fit a large antenna, or there are obstacles that block the radar’s signal. Be sure to confirm installation space and provide the manufacturer with tank dimensions, flange specifications, and even site photos.

4.3 Using a “One-Size-Fits-All” Approach

Don’t assume that if a certain model works for others, it will work for you too. Even within the same industry, conditions can differ— for example, the requirements for measuring hydrochloric acid are different from those for ethanol.

4.4 Not Considering After-Sales Support

Although 80G radars are generally stable, they still require periodic maintenance. Ask about maintenance methods, whether the antenna is easy to clean, if there are fault diagnostics, and how responsive the after-sales service is. Some manufacturers may have poor customer service, leading to long downtimes if issues arise.

5. The Final Step: A Selection Confirmation Checklist

To help you through the process, here’s a checklist you can use before finalizing your choice:

Measuring Medium: ______ (liquid/solid, viscosity, corrosiveness, crystallization)

Tank Height: ______ (meters), Measurable Range: ______ (meters)

Working Temperature: ______ (°C), Working Pressure: ______ (MPa)

Site Environment: ______ (explosion-proof, dust, interference sources)

Accuracy Requirements: ______ (e.g., ±1mm, ±5mm)

Installation Conditions: ______ (tank opening dimensions, installation method)

Communication Needs: ______ (local display/RS485/4-20mA/4G)

Special Requirements: ______ (sanitary, high-temperature, anti-material buildup, etc.)

Once you fill out this checklist, send it to the manufacturer, and they’ll be able to recommend the most suitable model. If you’re still unsure, it’s best to have the manufacturer send a technician for a site visit to ensure that the equipment meets your needs.