In industrial automation systems, control valves often appear bulky and are perceived as relatively simple devices. However, they operate under complex process conditions on pipelines, and any malfunction can result in operational delays, system instability, and even environmental issues. Given their critical role in ensuring process control quality, proactive measures to extend their service life are essential.

This article summarizes eight practical methods to improve the longevity of control valves, helping engineers minimize downtime and maintenance costs.

1. Operate at a Large Valve Opening

Start operating the control valve at the maximum possible opening (e.g., 90%). At large openings, cavitation and erosion occur primarily at the valve plug tip. As damage progresses, slightly close the valve to maintain flow control. This approach ensures the entire valve trim is gradually utilized until significant wear occurs on the plug root and sealing surfaces.

Benefits:

Reduces throttling erosion due to larger flow gaps.

Extends service life by 1–5 times compared to operation at small or mid-openings.

Example: A chemical plant doubled its control valve lifespan using this method.

2. Reduce System Pressure Drop Across the Valve

Minimize the pressure drop across the control valve by increasing resistance elsewhere in the system (e.g., installing an orifice plate downstream or partially closing a manual valve). This:

Forces the control valve to operate at a larger opening.

Reduces cavitation and erosion within the valve.

This method is particularly effective when oversized valves are installed and operating at small openings.

3. Downsize the Valve to Increase Operating Opening

Replace the existing valve with a smaller size (e.g., DN32 to DN25) or change to a smaller trim diameter.

Promotes larger operating openings.

Reduces throttling-induced wear.

Example: A chemical plant extended valve life by 100% after switching to a smaller trim size.

4. Shift the Damage Location

Redirect cavitation and erosion from critical areas such as the sealing surfaces to less critical parts of the valve body. This protects the valve plug and seat from premature damage.

5. Lengthen the Throttling Passage

Extend the valve seat to create a longer throttling channel. This:

Delays sudden flow expansion, moving the damage zone away from sealing surfaces.

Increases throttling resistance, reducing cavitation intensity.

Tip: Step-shaped or wave-shaped seat bores can further disrupt cavitation formation.

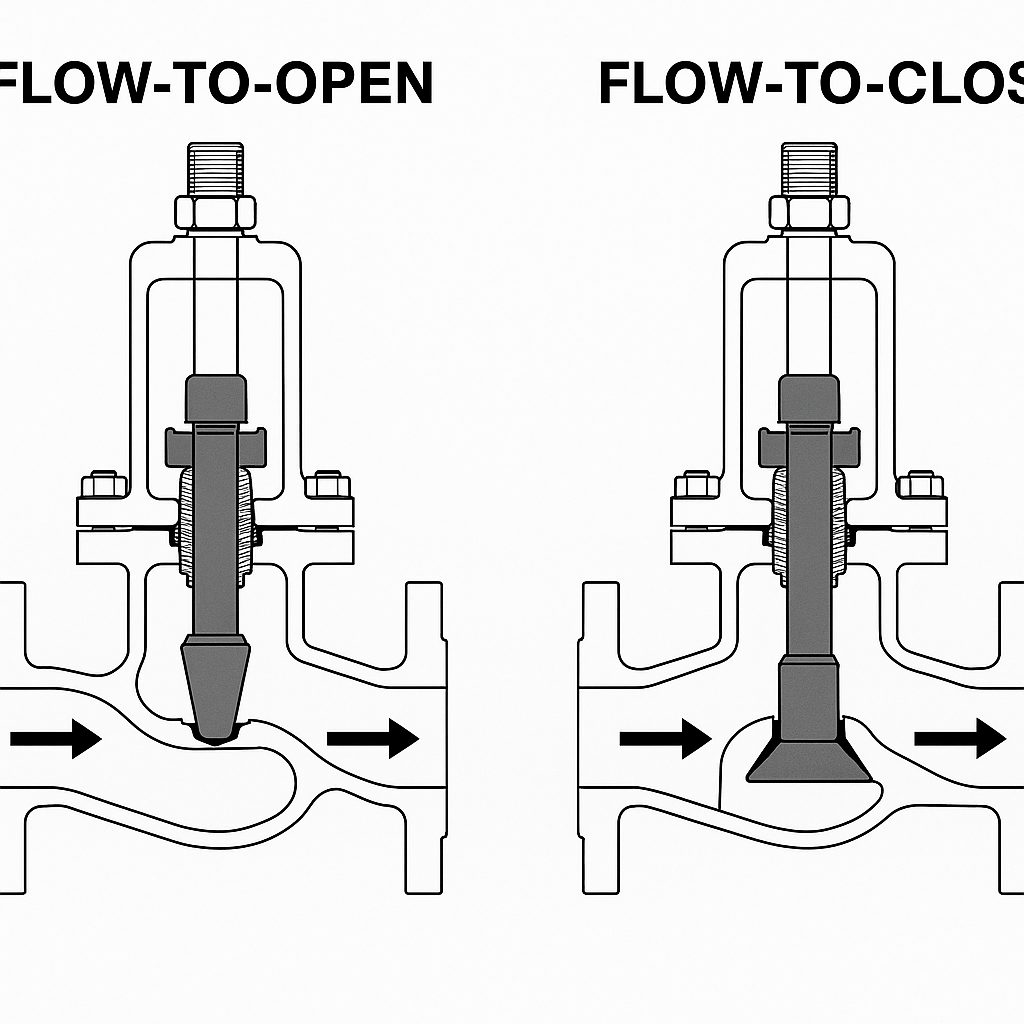

6. Reverse the Flow Direction

In “flow-to-open” configurations, cavitation and erosion often affect sealing surfaces. Changing to “flow-to-close” ensures these destructive forces act downstream of the sealing surfaces, significantly extending service life.

Impact: Extends valve life by 1–2 times.

7. Use Special Materials for Critical Parts

For cavitation and erosion resistance, use advanced materials for the trim:

Anti-cavitation and anti-erosion materials: Stellite, tungsten carbide, 6YC-1 alloy.

Anti-corrosion materials: PTFE, ceramics, Monel, Hastelloy.

Selecting materials with both mechanical and chemical resistance properties is key for aggressive media.

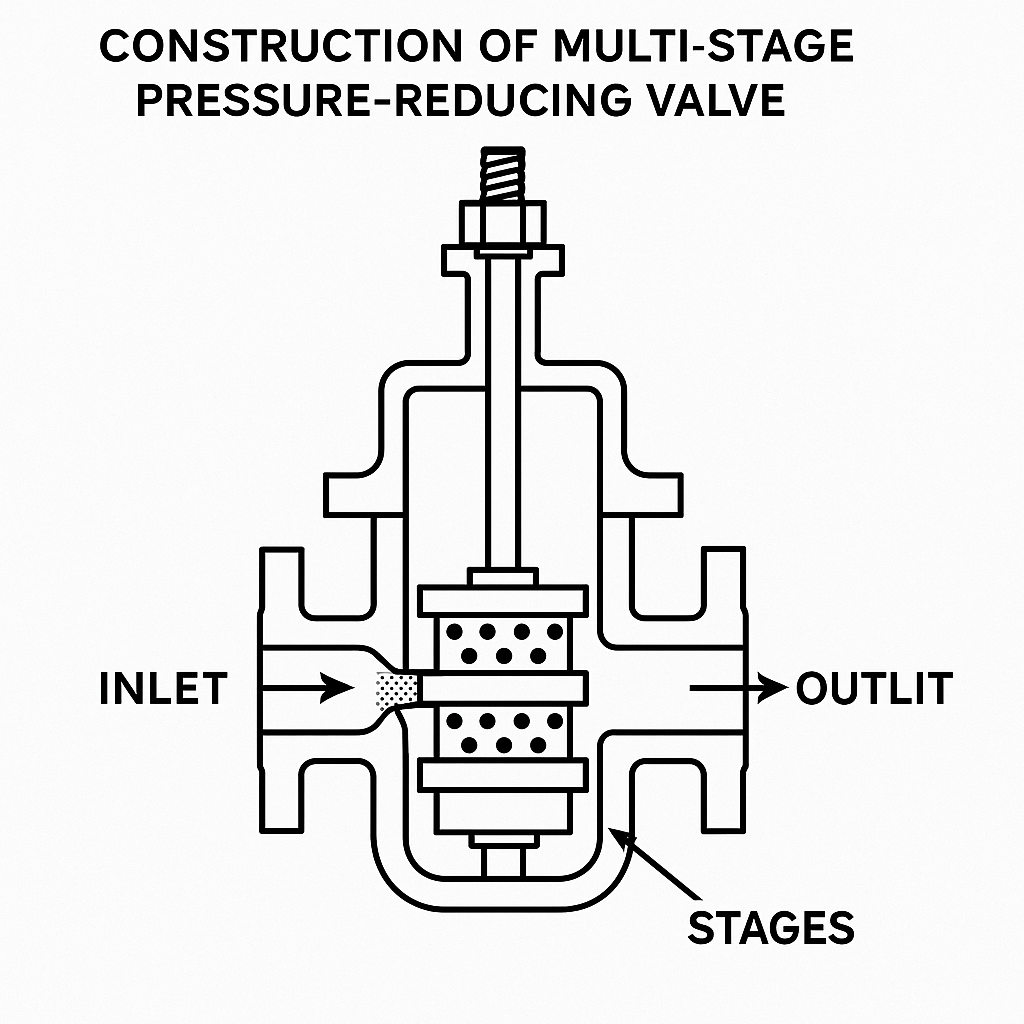

8. Upgrade Valve Design

Replace standard valves with designs optimized for challenging service:

Multi-stage pressure-reducing valves: To handle high pressure drops.

Anti-cavitation valves: To minimize vapor bubble formation.

Corrosion-resistant valves: For highly corrosive media.

✅ Conclusion

Applying these methods—either individually or in combination—can significantly enhance control valve reliability and service life. Careful selection of valve size, materials, and configuration during design and maintenance phases helps avoid premature failures and ensures smooth process operations.