Introduction

To select, operate, and maintain industrial instruments effectively, it is crucial to understand their key quality indicators. These parameters determine whether an instrument can perform reliably and accurately in demanding industrial environments. This guide outlines the six essential quality indicators: accuracy, hysteresis, sensitivity, dead zone, stability, and response time, helping engineers and decision-makers evaluate and select the right instruments for their applications.

1. Accuracy

Accuracy refers to the degree of conformity between the instrument’s reading and the true (or agreed) value of the measured parameter. It encompasses influences such as systematic errors, random errors, hysteresis, and dead zones.

Accuracy is often expressed as a percentage of span:

Accuracy (%) = (Absolute Error / Full Scale Range) x 100

Where:

Absolute Error (ΔC) = |Measured Value – True Value|

Full Scale Range = Upper Limit (Amax) – Lower Limit (Amin)

Instruments are classified into accuracy grades, e.g., 0.1%, 0.5%, 1.0%. The lower the grade number, the higher the accuracy.

Example: A temperature indicator with a range of 0-800°C and an accuracy grade of 0.5% will have a maximum permissible error of ±4°C.

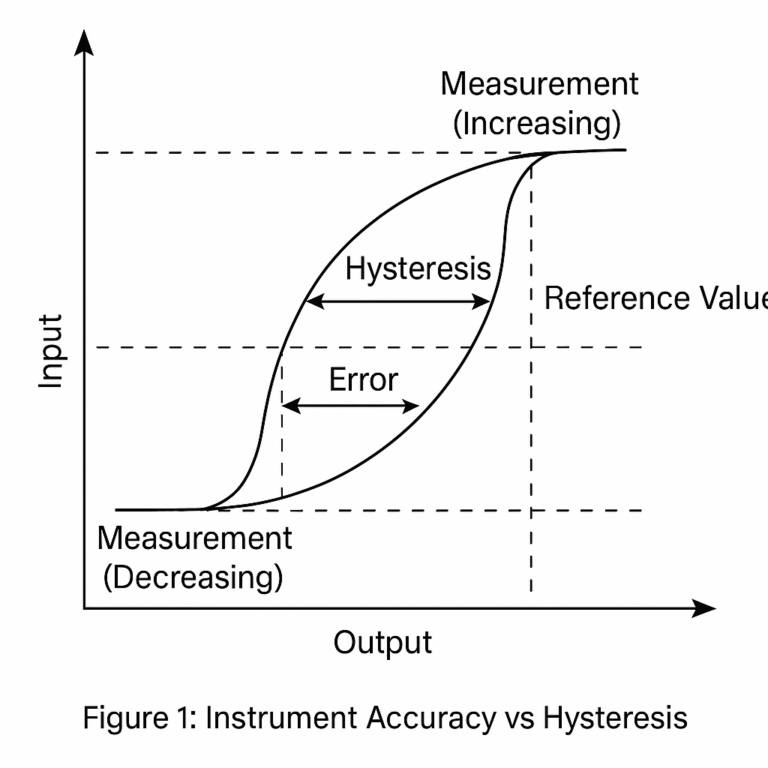

2. Hysteresis

Hysteresis represents the difference in output when the same input is approached from increasing and decreasing directions. It is expressed as:

Hysteresis (%) = (Maximum Difference / Full Scale Range) x 100

Key Point: During calibration, perform both upward and downward measurements to detect hysteresis. Instruments with high hysteresis may give inconsistent readings.

3. Sensitivity

Sensitivity defines the ratio of output signal change to the corresponding input signal change:

Sensitivity (S) = Output Change (Δα) / Input Change (ΔA)

A high sensitivity means the instrument can detect small changes in the measured parameter.

Instruments should ideally have linear sensitivity across their range.

Note: Excessive sensitivity can amplify noise in the signal.

4. Dead Zone (Dead Band)

The dead zone is the range of input signal variation where the instrument does not respond. It is critical for applications requiring fine resolution.

Example: A temperature sensor only reacts when the temperature increases by 0.2°C or decreases by 0.3°C. The dead zone at this point is 0.5°C.

Rule of Thumb: The dead zone should not exceed half of the permissible error for the instrument.

5. Stability

Stability refers to the ability of an instrument to maintain consistent performance over time and under varying environmental conditions.

Time Stability: Resistance to drift over prolonged operation.

Environmental Stability: Sensitivity to temperature, humidity, and vibration.

Tip: Choose instruments with excellent stability for long-term installations or critical processes.

6. Response Time

Response time is the delay between a change in the measured parameter and the instrument’s display of this change.

Fast response time is essential in processes where parameters fluctuate rapidly.

Slow instruments are unsuitable for dynamic processes but may be acceptable for steady-state monitoring.

Summary Table: Six Quality Indicators

| Indicator | Definition | Importance |

|---|---|---|

| Accuracy | Closeness of measurement to true value | Critical for precise control |

| Hysteresis | Difference between upward and downward readings | Impacts repeatability |

| Sensitivity | Output change per unit input change | Affects detection of small variations |

| Dead Zone | Range where no output change occurs despite input change | Limits resolution |

| Stability | Ability to maintain performance over time | Crucial for long-term reliability |

| Response Time | Time taken for instrument to react to input change | Essential for fast-changing processes |