Ore slag is an important industrial raw material, and the accurate monitoring of its storage volume plays an indispensable role in production scheduling and resource management.

With the advancement of science and technology, traditional measurement methods are gradually replaced by higher-precision and more intelligent instruments.

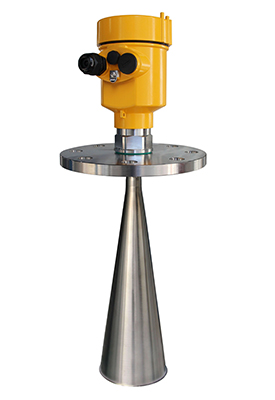

As a new type of level measurement equipment, radar level meter is widely used in level measurement of various materials due to its non-contact measurement and high precision characteristics.

This article will explore whether ore slag can be measured using radar level meters and analyze its feasibility.

Radar level meter is a device that uses microwave signals for level measurement. It calculates the level height by transmitting microwave signals and receiving the reflected signals.

The advantage of this technology is that it is not affected by changes in the medium and can penetrate harsh environments such as steam and dust to achieve accurate measurements. Ore slag is usually composed of solid waste generated during the refining process of metallic minerals and has certain electrical conductivity and dielectric constant.

These characteristics determine the reflection and attenuation of radar waves during propagation, thereby affecting the measurement effect of the radar level meter. In actual measurements, the performance of the radar level meter is affected by many factors, including the particle size, humidity, stacking angle of the slag, and the shape of the container.

For example, when the particle size of slag is large, it may cause scattering of microwave signals, thus affecting the accuracy of the measurement. In addition, changes in the humidity of the slag will also affect its dielectric constant, thereby changing the microwave propagation characteristics.

In order to ensure that the radar level meter can perform optimally in the measurement of ore and slag, the following aspects need to be considered:

1. Select a suitable radar level meter model. According to the specific characteristics of the ore slag, select a suitable radar level meter model to ensure that its operating frequency and power can meet the measurement needs.

2. Optimize the installation location and method. Reasonable installation position can reduce the impact of slag accumulation on measurement and improve measurement accuracy. At the same time, using appropriate installation methods can ensure the stability and reliability of the radar level meter.

3. Perform on-site calibration. Because the characteristics of ore slag may change over time and environment, regular on-site calibration is a critical step to ensure measurement accuracy.

4. Combine with other measurement techniques. In some special cases, the use of radar level meters alone may not meet the measurement requirements. At this time, you can consider using it in combination with other measurement technologies such as ultrasonic level meters to improve the reliability of measurement.

Ore slag can be measured using radar level meters, but it is necessary to select the appropriate equipment model according to the specific situation and optimize the installation and use process.

Through scientific methods and meticulous operation, radar level meters are fully capable of providing accurate data support for level measurement of ore and slag, ensuring the efficiency and safety of industrial production.