Many consider Advanced Process Control (APC) to be a superior alternative to the traditional Proportional-Integral-Derivative (PID) controller. However, the reality of industrial applications is that the selection of control strategies is not solely determined by whether an algorithm is labeled as “advanced,” “intelligent,” “adaptive,” or “optimal.” Instead, the primary concern of industry practitioners is cost-effectiveness. Industrial engineers prioritize the democratization of technology, ensuring that complex control solutions can be widely and affordably implemented without being overly dependent on specialist expertise.

PID controllers, despite not being the most efficient in every situation, remain widely used due to their simplicity and affordability. Conversely, many advanced control algorithms, while theoretically superior, fail to gain widespread adoption because of their high cost and implementation complexity.

The Enduring Legacy of PID in Process Control

A review of process control history reveals that every era of automation has been marked by claims of “advanced intelligence,” yet PID remains at the heart of control systems. Originally developed before modern control theory, PID has survived and adapted across different technological paradigms—from pneumatic and mechanical systems to electronic and digital controls.

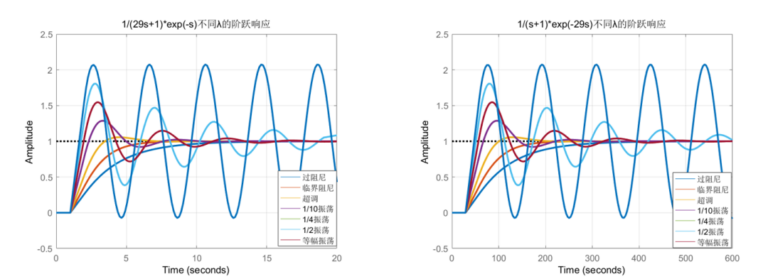

In single-variable control, PID is particularly effective for processes with large time constants and significant dead time. Recent studies indicate that PID, when properly tuned, can handle step response characteristics such as overdamping, critical damping, overshoot, and oscillatory behaviors (including 1/10, 1/4, 1/2, or sustained oscillations).

For first-order processes with dead time, a well-tuned PI controller often acts as an optimal controller. Many low-order linear controllers used in industry today are essentially simplified PID variations. Moreover, even when controlling complex high-order nonlinear processes, PID remains a standard engineering approach due to its robustness. Historically, attempts to replace PID with alternative algorithms in single-variable control have not been particularly successful. PID has remained a dominant force in process control, standing the test of time.

PID as a Model-Based Control Algorithm

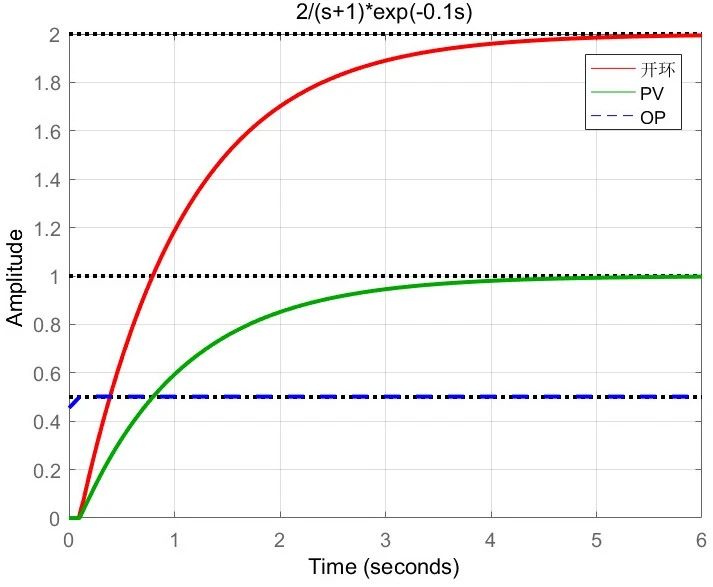

Both PID and APC are fundamentally model-based control strategies. From the Lambda tuning method, we can see that precisely tuned PID parameters depend on the process model. In systems with large time constants, selecting an appropriate Lambda parameter allows the controller to generate stable, near-optimal control responses, almost as if the system’s output had been predicted. Moreover, the closed-loop response speed of the process can be accurately defined. This demonstrates that PID is implicitly model-based, even if its implementation does not require an explicit process model.

One of the main reasons for PID’s resilience in process control is its robustness. Unlike model-predictive controllers, PID can maintain stability even when the process model is inaccurate, which is crucial in industrial environments where obtaining an exact process model is challenging due to dead time, uncertainties, and nonlinearities. Process control fundamentally involves achieving acceptable performance in uncertain and constrained environments, and PID has proven to be a reliable tool in this regard.

The Limitations of PID in Modern Industrial Applications

Despite its robustness and longevity, PID is not without its drawbacks. The rapid expansion of industrial systems post-World War II, combined with declining control hardware costs, has led to increasingly complex process control challenges, particularly in multi-variable environments.

While engineers have developed many PID-based strategies—such as cascade control, feedforward control, split-range control, and override control—to address multi-variable interactions, these approaches often introduce significant complexity. The design and tuning of such control schemes require deep system understanding, making them difficult for engineers to master. The effectiveness of PID-based solutions depends heavily on individual expertise, which is a significant hurdle in industrial practice where standardization and repeatability are highly valued.

The Role of APC in Multi-Variable Control

APC provides a structured and cost-effective approach to solving multi-variable control problems. By transforming multi-variable control challenges into optimization and control problems, APC enables systematic tuning and deployment. Although originally perceived as an advanced replacement for PID, predictive control methodologies such as Model Predictive Control (MPC) have existed alongside traditional techniques like Smith Predictors and Linear Quadratic Gaussian (LQG) control for decades.

The industrial adoption of APC has been driven by its ability to provide a flexible and low-cost alternative to complex PID-based strategies. The key to leveraging APC effectively is understanding that its primary advantage lies in standardizing multi-variable control, rather than merely replacing PID with a more complex algorithm.

Beyond Control: Optimization and Process Efficiency

Once stable control is achieved, further benefits can be realized through constraint optimization and setpoint adjustments. In this context, APC allows engineers to manage remaining degrees of freedom in a process, facilitating operational optimization. However, it is important to recognize that optimization efforts must be part of a broader strategy—APC alone cannot generate significant process improvements without complementary engineering efforts.

Conclusion: PID and APC as Complementary Tools

A well-tuned PID controller remains highly effective for single-variable control problems. However, as process complexity increases, PID-based multi-variable control schemes become cumbersome and difficult to implement effectively. In contrast, APC provides a structured, scalable, and cost-effective solution for managing multi-variable interactions.

Rather than viewing APC as a complete replacement for PID, engineers can benefit from studying APC methodologies to gain a deeper understanding of process control principles. Mastery of APC can enhance the ability to design and tune PID-based strategies, leading to more effective use of process control tools overall.

For industrial practitioners, the key takeaway is that PID and APC should be seen as complementary rather than competing approaches. The best results arise from integrating the strengths of both methodologies, ensuring optimal performance while maintaining cost-effectiveness and practical feasibility in real-world applications.