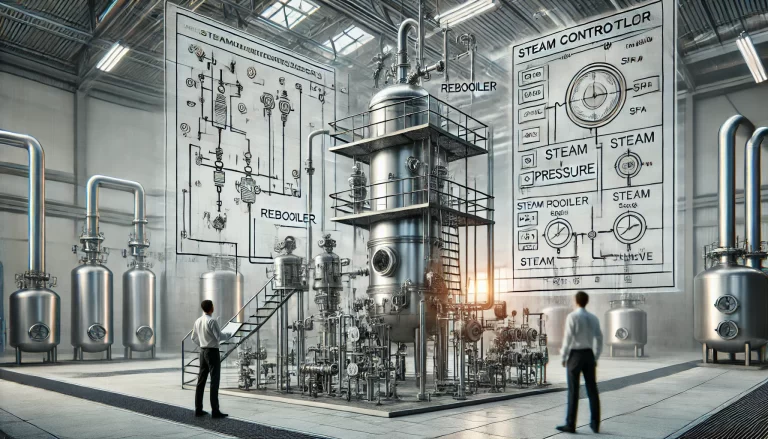

In a recent industrial installation, the reboilers of a distillation column were configured to use steam pressure control. However, concerns were raised regarding the stability of incoming steam pressure, leading to the suggestion of switching to flow control. This proposal included the addition of a steam flowmeter and updating the control scheme. Since this involves significant investment, a careful evaluation is necessary. It is essential to identify the root cause of the problem and achieve feasible control objectives within the constraints.

Current Scenarios in Similar Systems

In the same facility, another unit uses steam pressure control for a saponification column, while flow control is employed for the reboilers of a distillation column. Both control schemes have been in use for years without issues, and there are no plans for modifications.

The argument for switching from pressure control to flow control in the reboilers is based on the observation that fluctuations in the distillation process are linked to the instability of incoming steam pressure. While this may be a contributing factor, is it truly the root cause? Can switching to flow control effectively resolve the issue? At this stage, the answer is unclear. Given the investment involved, any recommendations for equipment changes should be approached with caution, prioritizing knowledge gained from operations.

Potential Solutions

Three practical approaches have been identified to address the problem:

Minimal Adjustment with Manual Intervention:

- If the reboiler valve operates with minimal opening, there may be no need to install a flowmeter. Under such constraints, manual valve adjustment has been shown to maintain acceptable control performance without significant energy consumption.

Optimizing PID Parameters:

- Conducting a thorough PID parameter tuning for the steam pressure and all related control loops can stabilize the distillation process. This method leverages existing equipment and has been successfully implemented in other setups without requiring additional investment.

Advanced Control Techniques:

- In some cases, automatic pressure control of reboiler steam has caused tower-wide fluctuations. Switching the pressure control valve to manual operation, coupled with advanced control strategies for the entire column, has achieved process stability.

These solutions reflect diverse problem-solving strategies. The first approach accommodates limitations to achieve acceptable performance. The second explores the full potential of existing systems, while the third redefines the problem by creatively using available resources.

Evaluating Instrumentation Upgrades

Will switching from pressure to flow control solve the issue? Generally, altering constraints to optimize control performance can be beneficial. However, the focus should remain on addressing problems within existing limitations before resorting to costly changes.

For example, in colder climates, issues with steam pressure may be exacerbated by inadequate insulation. Improving insulation could yield immediate benefits without the need for significant investment. In warmer regions, this might not be a concern, but each environment demands tailored solutions.

Insights from Related Systems

In similar control scenarios, such as furnace outlet temperature control, single-loop or cascade control is commonly used. The cascade control scheme often involves fuel gas pressure or flow as the secondary loop. Before implementing major changes, engineers typically fine-tune PID parameters and stabilize external conditions to meet control objectives. Only if these measures prove insufficient is it necessary to consider altering constraints or investing in new equipment.

Conclusion

A problem-solving mindset that incorporates structure, constraints, and trade-offs is essential for creative engineering solutions. Ignoring a problem or dismissing its proposer is not a solution—it simply indicates that a feasible method has yet to be found.

To effectively address the issue of steam control in reboilers, a systematic approach should be adopted:

- Identify the root cause of process instability.

- Optimize current control schemes through parameter tuning and operational adjustments.

- Consider equipment upgrades only after exhausting cost-effective alternatives.

The ability to innovate within constraints is what distinguishes successful engineering practices.