The idea that electrical and instrumentation (E&I), equipment, and safety are “three independent silos” is a perspective that may seem plausible but does not reflect reality in well-managed organizations. However, in situations where communication and management are lacking, such silos may indeed arise, leading to inefficiencies or even operational risks.

Understanding the Roles of E&I, Equipment, and Safety

Each domain has its unique focus, which can sometimes create a perception of isolation:

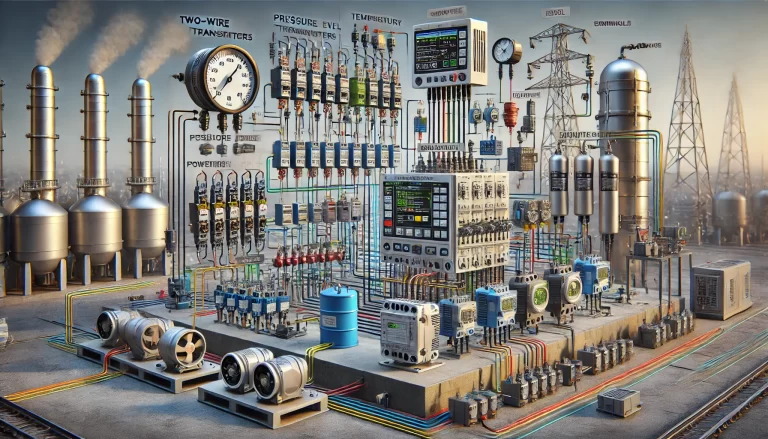

Electrical and Instrumentation (E&I):

E&I teams focus on the operation, maintenance, and calibration of electrical systems and instrumentation. Their primary responsibility is ensuring the accuracy of instrumentation signals and the stability of electrical systems. For example, they manage sensors that monitor parameters like temperature, pressure, and liquid levels, and control systems that regulate equipment operations.Equipment:

The equipment team emphasizes the mechanical aspects of operations, such as performance, efficiency, and lifespan. Their work revolves around maintaining machinery, minimizing wear and tear, and optimizing production capacity.Safety:

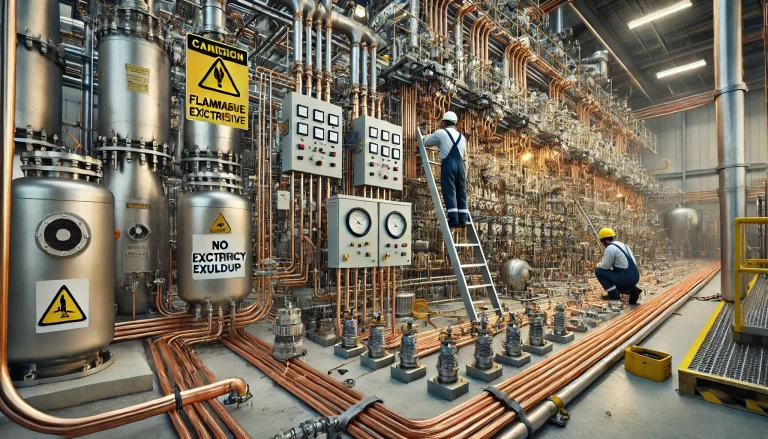

Safety teams are tasked with identifying, assessing, and mitigating risks to ensure the health and well-being of personnel and protect organizational assets. Their work includes creating safe operational procedures, implementing warning systems, and ensuring compliance with safety regulations.

The Risk of Silos

In some organizations, these three domains may be managed by separate departments, each with its own objectives, processes, and metrics. When communication and coordination are inadequate, this separation can result in information gaps and operational inefficiencies.

For example:

- A new piece of equipment is installed by the equipment team without notifying the E&I department. As a result, the necessary adjustments to instrumentation and electrical systems are delayed.

- Simultaneously, the safety team may not conduct a timely risk assessment, leaving potential hazards unaddressed.

These oversights create a cascading effect, where the lack of alignment impacts productivity, safety, and operational reliability.

The Interdependence of E&I, Equipment, and Safety

Despite their distinct responsibilities, E&I, equipment, and safety are inherently interconnected. In industrial environments, their collaboration is crucial for seamless operations:

E&I as a Support for Equipment:

Electrical and instrumentation systems are essential for monitoring and controlling equipment performance. For instance, in automated production lines, sensors (managed by E&I teams) continuously track key parameters like pressure and temperature. Any deviation triggers adjustments in the control system to maintain optimal equipment performance.Equipment’s Impact on Safety:

The mechanical state of equipment directly influences safety. Equipment failures—such as mechanical damage or prolonged overloading—can lead to accidents. For instance, an overheating motor due to overloading may catch fire, posing risks to personnel and infrastructure.Safety as a Guiding Framework:

Safety measures establish the standards and protocols for E&I and equipment operations. This includes ensuring proper system installation, regular inspections, and the implementation of safety mechanisms such as emergency stop buttons or protective barriers. These measures minimize risks during both normal and abnormal operating conditions.

Bridging the Gap: Enhancing Collaboration

To overcome the challenges of silos and fully leverage the synergy between E&I, equipment, and safety, organizations can adopt several strategies:

Cross-Functional Communication:

Regular meetings and shared communication channels between departments ensure that information flows freely. For example, an equipment upgrade plan should be discussed in advance with E&I and safety teams to align their contributions.Integrated Management Systems:

Adopting digital platforms for data sharing can improve transparency and efficiency. A centralized system can track equipment performance, E&I calibration schedules, and safety audits, enabling real-time collaboration.Joint Training Programs:

Conducting training sessions that include all three teams fosters mutual understanding of each other’s roles and responsibilities, creating a culture of cooperation.Early Involvement in Projects:

All three domains should be involved from the initial stages of any project. For example, before installing a new production line, E&I and safety teams should work alongside the equipment team to ensure smooth integration and risk mitigation.

Conclusion

E&I, equipment, and safety are not independent silos but interdependent pillars that support industrial operations. When these domains work in isolation, organizations risk inefficiency, safety incidents, and operational setbacks. However, by fostering communication, collaboration, and shared accountability, companies can align these domains to create a seamless, safe, and efficient working environment. Breaking down silos is not just about improving processes—it is about building a culture of teamwork that drives long-term success.