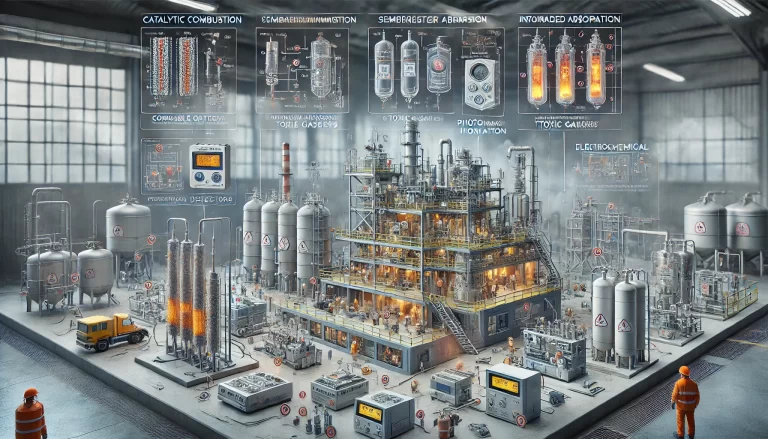

Gas detectors play a crucial role in ensuring safety by identifying potentially hazardous gases in various environments. This article explores the working principles and types of detectors for both combustible and toxic gases.

1. Combustible Gas Detectors

Combustible gas detectors are essential for monitoring environments prone to flammable gases. Common types include catalytic combustion, semiconductor, and infrared absorption detectors. Below are their principles and application details.

1.1 Catalytic Combustion Type

- Principle: Combustible gases react with oxygen on the surface of the catalytic sensor, causing flameless combustion. This reaction increases the temperature of the detection element.

- How It Works:

- The temperature rise changes the resistance of the detection element within a Wheatstone bridge circuit.

- This disrupts the circuit’s balance, generating an electrical signal proportional to the gas concentration.

- The signal is amplified and processed to trigger an alarm.

- Applications: Commonly used in industrial environments such as refineries, chemical plants, and gas storage facilities.

1.2 Semiconductor Type

- Principle: The gas-sensitive semiconductor element absorbs combustible gas molecules, altering its electronic properties.

- How It Works:

- Adsorption causes changes in the element’s resistance.

- The resistance change is converted into an electrical signal.

- Once the signal reaches a preset threshold, the alarm is activated.

- Applications: Widely deployed in home safety systems and small-scale industrial sites.

1.3 Infrared Absorption Type

- Principle: Different gases absorb specific wavelengths of infrared light. When infrared light passes through a gas, the intensity of the absorbed wavelength correlates to the gas concentration.

- How It Works:

- Using the Beer-Lambert Law, the light absorption intensity is measured.

- The system calculates the gas concentration and triggers an alarm when it exceeds the safety threshold.

- Applications: Used in environments where traditional sensors may be affected by poisoning, such as in high-purity chemical production or pharmaceutical facilities.

2. Toxic Gas Detectors

Toxic gas detectors are critical for identifying harmful gases in confined spaces. Common types include electrochemical, semiconductor, and photoionization detectors.

2.1 Electrochemical Type

- Principle: Toxic gases interact with electrodes in the presence of an electrolyte, causing oxidation or reduction reactions that generate a measurable current.

- How It Works:

- As gas molecules enter the sensor, they undergo a chemical reaction at the electrode surface.

- The resulting current is directly proportional to the gas concentration.

- The signal is processed to display the concentration and trigger alarms when necessary.

- Applications: Commonly used to detect gases like carbon monoxide, hydrogen sulfide, and ammonia in workplaces, parking garages, and mining operations.

2.2 Semiconductor Type

- Principle: Similar to combustible gas detectors, toxic gas molecules interact with a metal oxide semiconductor, changing its resistance.

- How It Works:

- The interaction alters the sensor’s resistance, which is converted into an electrical signal.

- Amplified signals trigger alarms if gas levels surpass safe limits.

- Applications: Often found in factories handling volatile organic compounds or toxic chemicals.

2.3 Photoionization Type

- Principle: High-energy ultraviolet (UV) light ionizes gas molecules, generating charged particles.

- How It Works:

- UV light ionizes toxic gas molecules, producing positive ions and electrons.

- These ions create a current proportional to the gas concentration.

- When the concentration exceeds the set threshold, an alarm is activated.

- Applications: Ideal for detecting volatile organic compounds (VOCs) in laboratories and industrial settings.

3. Practical Applications and Maintenance

To maximize the effectiveness of gas detectors, selecting the right type for the application is essential. For example:

- Catalytic combustion detectors are ideal for detecting methane or propane in industrial zones.

- Infrared detectors excel in high-purity or corrosive environments.

- Electrochemical detectors are best suited for confined spaces requiring toxic gas monitoring.

Maintenance and Safety Tips

- Calibration: Regularly calibrate detectors to ensure accuracy.

- Sensor Replacement: Replace sensors based on the manufacturer’s recommendations, as they may degrade over time.

- Environmental Factors: Consider environmental conditions like humidity, temperature, and potential sensor poisoning when deploying detectors.

4. Conclusion

Combustible and toxic gas detectors are indispensable tools for safeguarding lives and property. By understanding their principles and applications, users can make informed decisions about the most suitable detectors for their needs. Whether for industrial, commercial, or residential settings, regular maintenance and proper usage are critical to ensuring reliable performance and safety.