1. Background

In steam turbine operation, condenser hotwell water level is a critical parameter. A stable level ensures:

Reliable condensate pump operation without cavitation.

Adequate condenser cooling area to maintain vacuum efficiency.

If the hotwell level is too low, condensate pumps may cavitate. If it is too high, condenser vacuum deteriorates, leading to unsafe turbine operation.

2. Case Description

During start-up of a 25 MW condensing turbine unit, the hotwell level showed abnormal behavior:

When condenser vacuum reached –93 kPa, the indicated hotwell level suddenly surged from 650 mm to 1600 mm.

Condensate pump pressure fluctuated, accompanied by loud cavitation noise.

Inspection revealed that the impeller was damaged by cavitation.

However, when the water level gauge drain valve was opened, only a small amount of water was discharged — indicating a false water level rather than an actual high level.

3. Root Cause Analysis

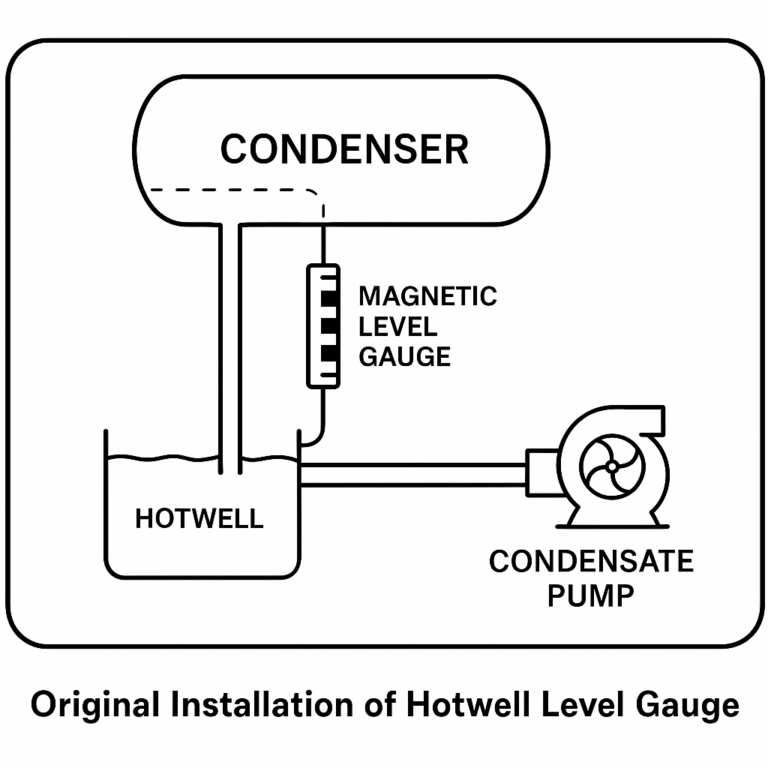

The original installation used a magnetic level gauge (range 0–1600 mm) with:

Lower connection at 65 mm above hotwell bottom.

Upper connection at condenser mid-section, linked by a DN32 pipe (1060 mm long).

Distance of only 500 mm from the condenser vacuum suction port.

When vacuum exceeded –93 kPa, the float inside the magnetic gauge was drawn to the top, giving a false high-level reading. This misleading indication caused improper pump operation and cavitation damage.

4. Corrective Action

The condenser manufacturer was consulted, and the installation was modified as follows:

A new DN25 port was opened at the top of the hotwell.

The gauge was replaced with a 0–1100 mm magnetic level gauge.

Lower connection remained unchanged; upper connection relocated to the new top port.

Result: After modification, the unit successfully synchronized without false level indications, and no cavitation reoccurred.

5. Preventive Measures

To further improve reliability:

An additional electric contact level gauge was installed opposite the magnetic gauge.

Both gauges were integrated into the DCS with a 2-out-of-2 voting logic.

Only when both gauges reported HH (high-high) or LL (low-low) alarms would the interlock trigger.

This redundancy ensured operational safety, allowing operators to cross-check readings and avoid unnecessary shutdowns.

6. Conclusion

This case highlights three key lessons:

Installation position matters — gauge connections should avoid areas near vacuum suction lines.

False level recognition — operators must be able to distinguish between true and false indications.

Dual instrumentation is essential — redundant level gauges with logical voting significantly enhance turbine reliability.