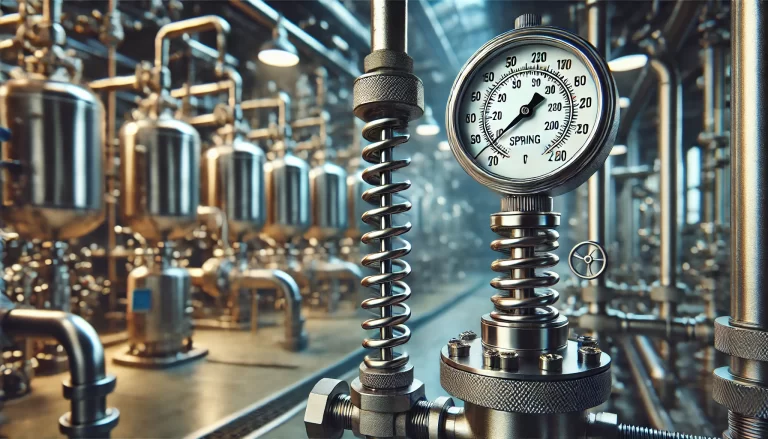

Industrial bimetallic thermometers are widely used for temperature measurement in various industrial applications, including manufacturing, chemical processing, and HVAC systems. These thermometers operate based on the principle of thermal expansion of two different metals, which causes the needle to move and display the temperature reading. However, in certain conditions, their performance can be affected by external factors such as vibration, moisture, and extreme temperatures. To enhance the durability and accuracy of bimetallic thermometers, a special liquid, often oil, is added inside the casing. But why is this necessary? Below are the key reasons why oil is added to industrial bimetallic thermometers.

1. Minimizing Needle Vibration and Ensuring Stable Readings

In industrial environments, machines and equipment often generate significant vibrations, which can cause the needle of a thermometer to oscillate rapidly. This results in an unstable reading, making it difficult for operators to obtain an accurate temperature measurement. By adding a damping fluid, such as silicone oil or glycerin, the internal movement of the needle is stabilized, reducing fluctuations and allowing for a more precise and easily readable temperature display.

2. Preventing Internal Condensation

Temperature fluctuations in industrial settings can lead to condensation forming inside the thermometer’s dial casing. This condensation can obscure the display and potentially cause corrosion of internal components. By filling the thermometer with oil, moisture is displaced, significantly reducing the chances of condensation forming. This ensures a clear and legible display, even in environments with high humidity or frequent temperature changes.

3. Enhancing Longevity and Durability

The internal components of a bimetallic thermometer, including the needle mechanism, are subject to wear and tear over time. The addition of oil acts as a lubricant, reducing friction between moving parts and minimizing mechanical degradation. This extends the lifespan of the thermometer and ensures reliable performance over an extended period.

4. Improving Performance in Extreme Temperatures

Bimetallic thermometers are used in environments with extreme temperature variations, from freezing cold to high heat. In cold temperatures, air inside the casing can freeze, affecting the responsiveness of the needle. In high-temperature environments, rapid temperature changes can cause internal stress. By using a specialized oil with suitable thermal properties, the thermometer remains functional and accurate across a wider temperature range.

5. Protection Against Corrosive Environments

In industries such as chemical processing and marine applications, thermometers may be exposed to corrosive substances that could damage internal components. Oil-filled thermometers provide an added layer of protection, reducing exposure to air and harmful chemicals that could lead to corrosion. This is particularly beneficial for applications involving aggressive gases, acids, or saline environments.

Types of Oil Used in Bimetallic Thermometers

Several types of damping liquids can be used inside bimetallic thermometers, each with specific properties suited for different applications:

Silicone Oil: Offers excellent temperature stability and is suitable for both high and low-temperature environments.

Glycerin: Commonly used in moderate-temperature applications due to its good viscosity and damping characteristics.

Mineral Oil: Sometimes used for cost-effective solutions, though it may not perform as well in extreme temperatures.

Conclusion

Adding oil to industrial bimetallic thermometers serves multiple functions, including stabilizing readings, preventing condensation, enhancing durability, and improving performance in harsh environments. This simple yet effective modification helps ensure accurate temperature monitoring, reduces maintenance needs, and extends the lifespan of the thermometer. Choosing the right type of oil based on operational conditions is crucial to maximizing the benefits of this technique. As industries continue to demand higher precision and reliability in temperature measurement, oil-filled bimetallic thermometers remain a vital solution for overcoming environmental challenges.