In industrial environments, especially those involving dusty, viscous, or condensable media, accurate and reliable measurement of pressure and temperature requires more than just selecting the right sensor. The design and installation orientation of the impulse line (short tapping pipe or stub) plays a critical role in ensuring consistent readings and preventing blockage or drift.

One frequently overlooked but highly effective practice is the inclined installation of impulse lines. This article outlines when and why this method is recommended, how it prevents common issues, and provides practical guidelines for implementation.

🔍 Why Consider an Inclined Impulse Line?

Impulse lines or tapping stubs are small-diameter pipes that connect the process medium to the pressure or temperature measuring instrument. In many installations, these lines are simply mounted vertically or horizontally. However, in certain process conditions, this can lead to measurement failures, including:

Blockage due to dust or solid particles

Condensation buildup or liquid pooling

Formation of solid deposits (e.g., crystallization, sludge)

Delayed or fluctuating pressure/temperature signals

Inclined installation helps mitigate these issues by promoting natural drainage or self-cleaning behavior, depending on the nature of the process fluid.

⚠️ When Is Inclined Installation Recommended?

| Application Scenario | Inclination Recommended? | Reason |

|---|---|---|

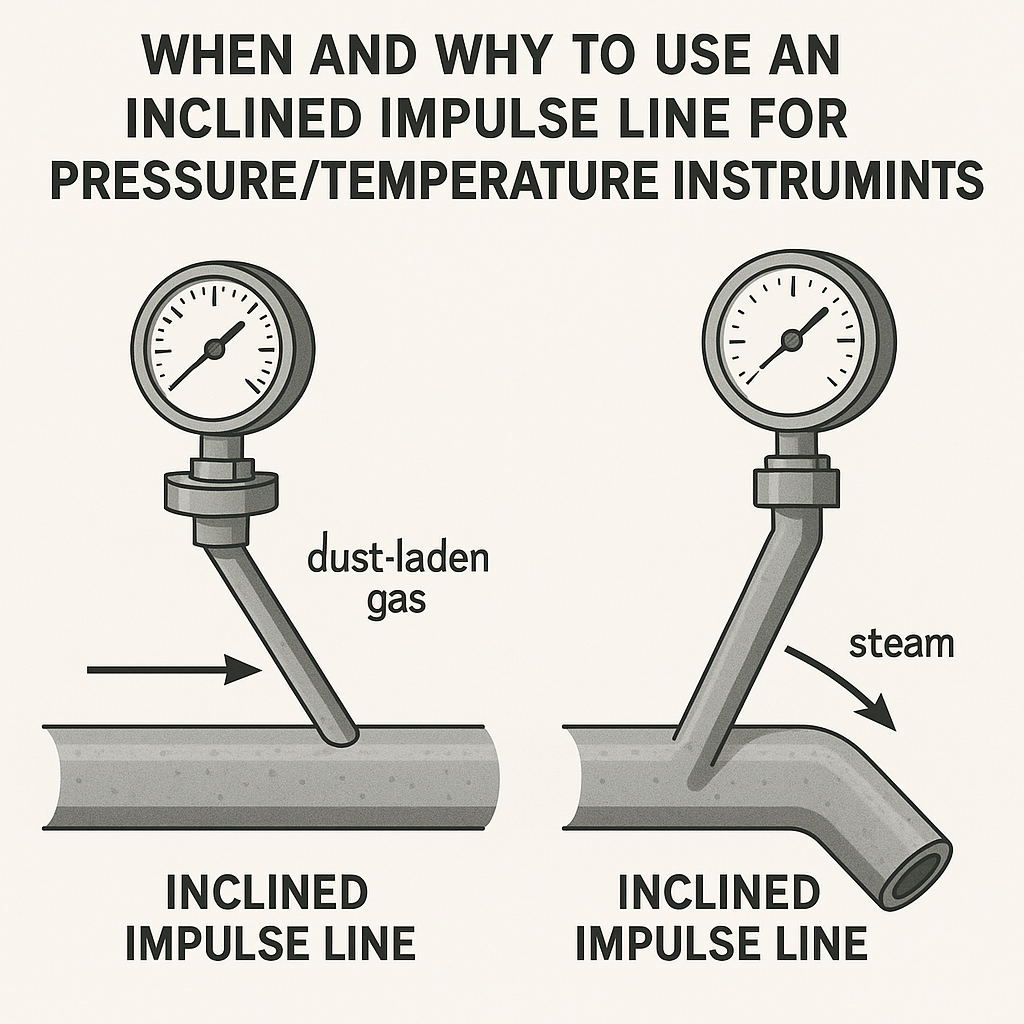

| Dust-laden gas (e.g., flue gas, gasification outlet) | ✅ Yes | Dust may accumulate in horizontal lines; upward inclination encourages particles to fall back into the process or flow through |

| Steam lines with condensate | ✅ Yes | Downward inclination allows condensed water to drain back, preventing “cold pockets” in temperature measurements |

| Liquids with crystallizing salts | ✅ Yes | Prevents stagnant zones where solids may accumulate and block the tap |

| Viscous fluids or heavy oils | ✅ Yes | Downward inclination allows better flow and avoids residual clogging |

| Clean, low-viscosity fluids or dry gases | ❌ Not necessary | Standard vertical/horizontal mounting usually suffices |

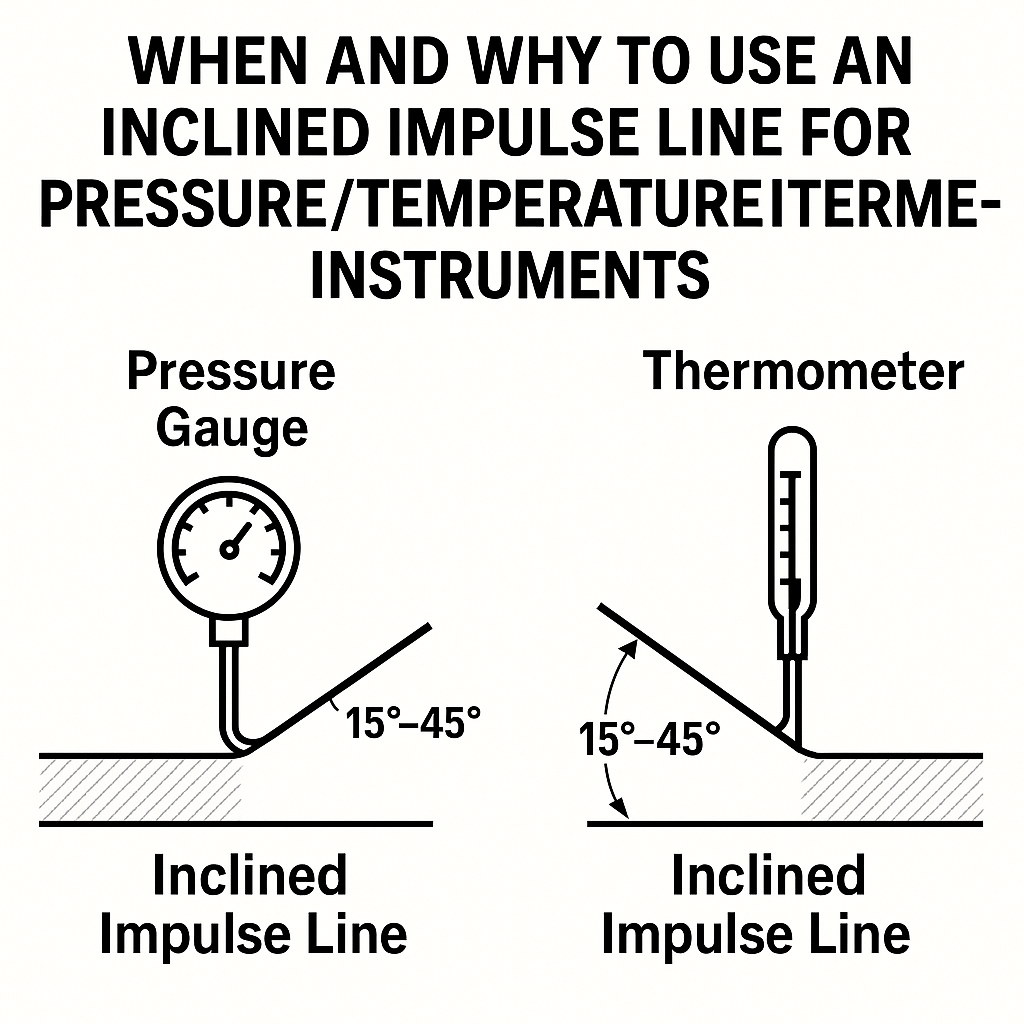

📐 Inclination Angle and Direction – Practical Guidelines

The optimal inclination angle and direction depend on the phase and characteristics of the process medium:

| Media Type | Inclination Direction | Suggested Angle | Purpose |

|---|---|---|---|

| Gas with particles | Upward from the tapping point | 15°–30° | Avoids particle settling in the line |

| Condensable vapor (e.g., steam) | Downward from the tapping point | 30°–45° | Facilitates condensate drainage back to process line |

| Crystallizing or sticky liquids | Downward | 20°–30° | Prevents deposit formation in dead zones |

| Standard clean fluid | Any direction | 0° | Not critical for clean, non-fouling services |

🧰 Other Installation Best Practices

Even with the proper inclination, additional precautions should be considered:

Use blowdown valves or flushing connections on impulse lines for periodic cleaning.

Minimize the length of the impulse line to reduce dead volume and improve response time.

Insulate or trace heat lines when measuring media prone to condensation or freezing.

Avoid sharp elbows or low points where media can stagnate or separate.

📌 Conclusion

In dusty, high-condensate, or fouling-prone applications, an inclined impulse line can drastically improve the performance and longevity of your pressure or temperature measurement instruments. This small design adjustment reduces maintenance, increases reliability, and ensures more accurate process control.

As a rule of thumb:

“If your process flows dirty, condensable, or sticky — incline your impulse line!”