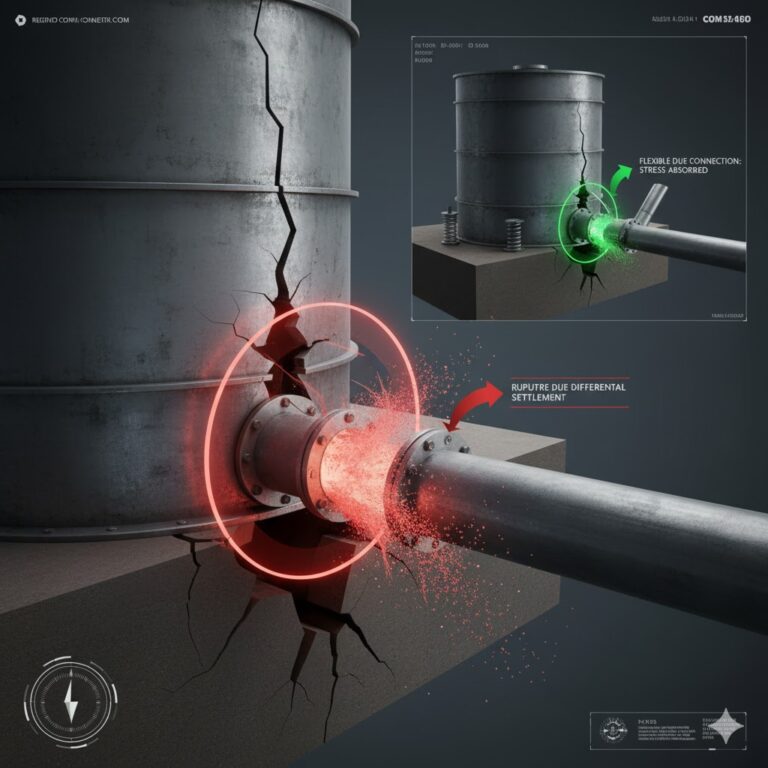

On October 17, 1989, the Loma Prieta Earthquake shocked the United States. Several oil refineries in the affected region saw their storage tanks torn apart, and the leaked oil ignited into a massive fire. Investigations revealed that the tanks were damaged primarily at the junction where the tank was connected to the outlet pipeline. This connection could not withstand the displacement caused by the earthquake.

What does this tell us?

In large petrochemical facilities, it’s not always the massive equipment that determines safety, but often an inconspicuous “flexible connection.” As a result, safety checks for hazardous chemical facilities frequently highlight this “key point”—the flexible connection at the tank outlet pipeline. It may sound complex, but its importance is undeniable because it determines whether a small deformation in the tank could lead to a major accident.

Why is it so Important?

Imagine a large water tank connected to a pipe at the bottom. If the ground sinks slightly, or temperature changes cause the pipe to expand or contract, or in the event of an earthquake, the connection between the tank and pipe may be forcibly torn apart. For storage tanks containing flammable and explosive substances, this is a ticking time bomb waiting to go off.

It’s like a person standing on the ground while holding a rope attached to a car that is shaking. When the forces aren’t synchronized, the “connection” will be torn apart. For storage tanks, this “connection” is the welds and nozzles. If they rupture, what leaks out isn’t just water, but possibly thousands of liters of flammable liquid.

What is a Flexible Connection?

Simply put, a flexible connection provides some “space to move” at the junction between the pipeline and the tank outlet. When foundation settlement, temperature changes, or external forces occur, these flexible designs act like a “shock absorber” to absorb and release stress, preventing the force from being directly transmitted to the welds or the tank wall.

In China, relevant standards have long mandated flexible designs for tank outlet pipelines:

The Petrochemical Storage and Transportation System Tank Area Design Code emphasizes that major inlet and outlet pipelines must use flexible connections to accommodate foundation settlement and seismic needs.

Sinopec’s rectification recommendations propose three common methods:

L-shaped, Z-shaped, or U-shaped pipeline arrangements: These utilize bending to naturally provide elasticity, which is simple and reliable, much like intentionally leaving slack when laying electrical cables to prevent them from breaking when stretched.

Metal hoses: These flexible “metal springs” can stretch and bend within a certain range and are ideal for limited spaces. The downside is that they require regular inspection to avoid fatigue damage.

Spring supports and hangers: These use springs to “bear” the weight and displacement of the pipeline, reducing stress at the connection points. These devices are especially effective in situations with significant thermal expansion, contraction, or settlement.

Additionally, the Petrochemical Pipeline Flexible Design Code also considers these requirements as basic design essentials.

In other words, this is not an “optional” feature, but a critical safety baseline.

Common Misconceptions and Warnings

In addition to the California earthquake, domestic accidents have also occurred due to foundation settlement, leading to tank leaks. In accident reports, the words “weld cracks,” “excessive nozzle stress,” and “lack of flexible connections” are frequently mentioned. These incidents often don’t occur because the risks weren’t recognized, but because:

Settlement monitoring was missing, and no one knew the tank was gradually sinking.

Cutting corners during installation, such as failing to remove locking mechanisms from spring supports.

Lack of maintenance, where metal hoses had become severely aged but weren’t replaced on time.

These small oversights, when combined, can trigger a disaster.

In actual projects, we often see two extremes:

Over-simplification: Some only add a single flexible hose at the tank opening, thinking this is enough, but the hose fails prematurely due to twisting and fatigue.

Blindly complicating the design: Some stack multiple compensators without directional or limiting devices, ultimately causing the pipeline to lose control.

The real challenge lies in:

Design engineers need to use stress analysis models to calculate force transmission.

Construction personnel must ensure installation accuracy.

Maintenance personnel must regularly inspect and review the system.

This forms a “full lifecycle” safety chain.

The Future of Flexible Connections

Today, with the rapid development of sensor and IoT technology, the maintenance of flexible connections no longer relies solely on human experience. More and more companies are using intelligent technologies, such as installing vibration and displacement monitoring devices on metal hoses to detect fatigue in real time, employing smart spring supports that automatically adjust load and upload operational data, and even building digital twin models to simulate the effects of foundation settlement or earthquakes on pipeline forces. This enables dynamic monitoring and predictive maintenance for flexible connections.

In the future, flexible connections may not just be “static structures,” but “living systems” that provide early warnings and even automatically adjust to ensure that tanks continue to operate within safe boundaries.

Conclusion: Details Determine Safety

Ultimately, the flexible connection at the tank outlet pipeline is a “safety buffer.” Its purpose is to provide a safe path that prevents the tank from tearing or leaking under inevitable conditions such as settlement, thermal expansion or contraction, or even an earthquake. In the world of industrial safety, there are no “insignificant problems.” Flexible connections are not just a “soft” solution, but a hard truth.