Instrument technicians play a crucial role in ensuring the proper functioning of industrial systems by maintaining, installing, and troubleshooting various instruments. A well-structured weekly study plan can help both beginners and experienced technicians enhance their knowledge and skills systematically. Below is a detailed plan designed for self-study.

Monday: Fundamentals of Instrumentation

- Objective: Understand the basic concepts and principles of instrumentation.

- Study Topics:

- Measurement Principles:

- Pressure: Types (gauge, absolute, differential) and measurement methods (bourdon tube, diaphragm).

- Temperature: Devices like thermocouples, RTDs, and thermistors.

- Flow: Measurement techniques such as electromagnetic, ultrasonic, and orifice plates.

- Level: Applications of float-based, radar, and ultrasonic level measurement.

- Overview of Instrumentation Types:

- Sensors, transmitters, controllers, and indicators.

- Typical usage in industries like oil & gas, pharmaceuticals, and manufacturing.

- Measurement Principles:

- Activities:

- Read introductory materials or watch tutorials.

- Identify and list different instruments in your workplace and their functions.

Tuesday: Electrical Fundamentals

- Objective: Develop a strong foundation in electrical concepts relevant to instrumentation.

- Study Topics:

- Basic Electrical Principles:

- Voltage, current, and resistance (Ohm’s Law).

- Understanding AC vs. DC circuits.

- Power calculations (P=VI).

- Circuit Components:

- Relays, switches, fuses, and contactors.

- Working with resistors, capacitors, and inductors.

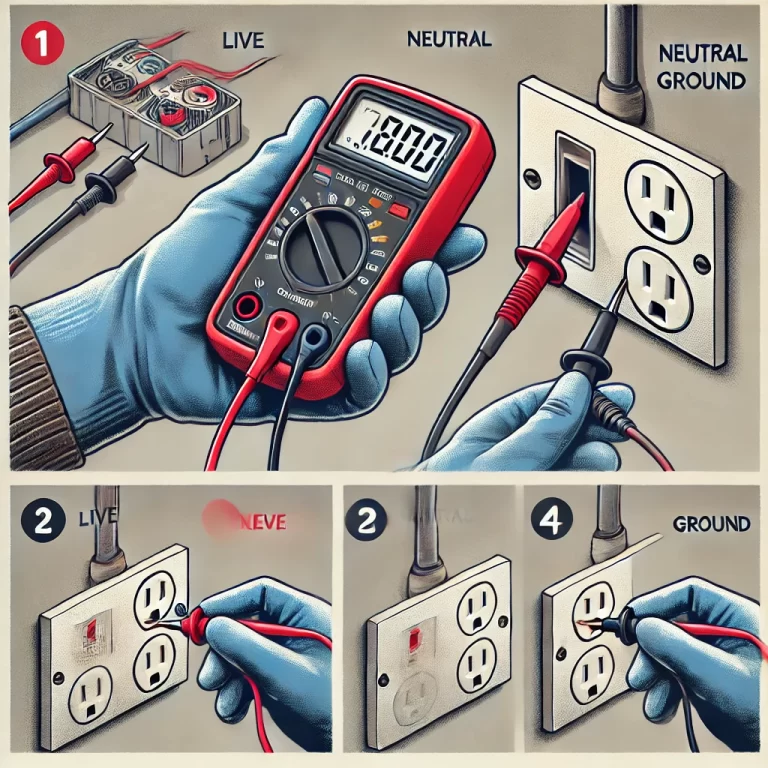

- Tools and Measurements:

- Using a multimeter to measure voltage, current, and resistance.

- Understanding how to use tools like an ammeter and clamp meter.

- Basic Electrical Principles:

- Activities:

- Perform simple electrical measurements.

- Build a basic circuit using resistors and a battery.

Wednesday: Instrument Installation and Maintenance

- Objective: Learn how to properly install, calibrate, and troubleshoot instruments.

- Study Topics:

- Installation Basics:

- Standard procedures for installing pressure and temperature transmitters.

- Pipe fittings, welding basics, and tubing layout.

- Calibration Techniques:

- Using a pressure calibrator or dead-weight tester.

- Calibrating a temperature transmitter with a dry block calibrator.

- Maintenance and Troubleshooting:

- Common issues: signal drift, sensor failure, communication errors.

- How to perform preventive maintenance and diagnostic tests.

- Installation Basics:

- Activities:

- Practice installing a simple sensor on a test setup.

- Simulate troubleshooting common issues.

Thursday: Automation and PLC Basics

- Objective: Explore the integration of instruments into automated systems.

- Study Topics:

- Programmable Logic Controllers (PLCs):

- PLC architecture: inputs, outputs, CPU, and programming interface.

- Basics of ladder logic programming.

- Introduction to HMI (Human-Machine Interface) systems.

- Communication Protocols:

- Analog signals: 4-20mA, 0-10V.

- Digital communication: Modbus, Profibus, and Ethernet/IP.

- Signal conditioning and noise reduction.

- Control Loops:

- Open vs. closed-loop control systems.

- PID control basics.

- Programmable Logic Controllers (PLCs):

- Activities:

- Write a simple PLC program (e.g., start/stop a motor with a push button).

- Connect an instrument to a PLC and observe data acquisition.

Friday: Case Studies and Application

- Objective: Apply knowledge to real-world scenarios and analyze practical applications.

- Study Topics:

- Industrial Case Studies:

- Analyze specific examples such as flow measurement in a chemical plant or temperature control in food processing.

- Instrument Selection:

- Criteria for selecting the right instruments based on application.

- Factors like accuracy, range, and environmental conditions.

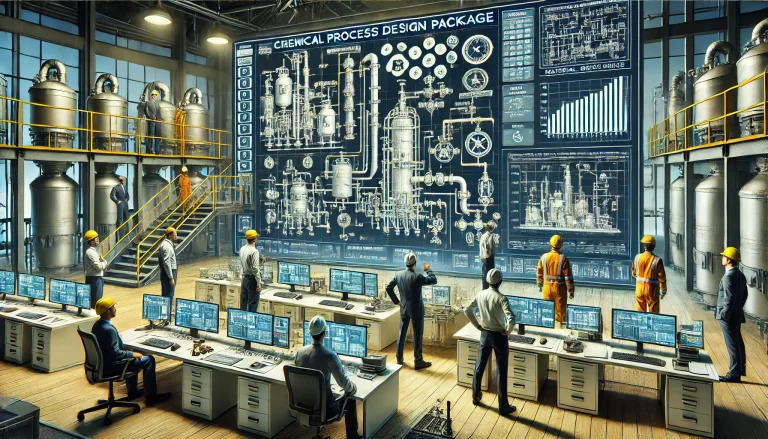

- Layout Design:

- Drawing a simple instrument loop diagram (ILD).

- Understanding Piping and Instrumentation Diagrams (P&ID).

- Industrial Case Studies:

- Activities:

- Study an industrial process flowchart and identify key instruments.

- Design a basic instrument setup for a given scenario.

Saturday: Safety and Standards

- Objective: Gain knowledge about safety practices and industry standards.

- Study Topics:

- Electrical Safety:

- Lockout-tagout (LOTO) procedures.

- Insulation testing and earthing requirements.

- Explosion-Proof Instruments:

- Intrinsically safe designs for hazardous environments.

- ATEX and IECEx certifications.

- Industry Standards:

- ANSI/ISA standards for instrument installations.

- Calibration and maintenance documentation.

- Personal Protective Equipment (PPE):

- Importance of PPE and its correct usage.

- Electrical Safety:

- Activities:

- Conduct a safety inspection of your work area.

- Familiarize yourself with safety regulations specific to your region.

Sunday: Review and Hands-On Practice

- Objective: Consolidate the week’s learning through review and practice.

- Activities:

- Review Notes:

- Revisit key concepts and notes from the week.

- Identify areas requiring more attention.

- Skill Testing:

- Practice installing, calibrating, or troubleshooting an instrument.

- Complete sample quizzes or certification-style questions.

- Plan Ahead:

- Set goals for the next week.

- Research additional resources like books or online courses.

- Review Notes:

Tips for Success:

- Use Reliable Resources:

- Books: Instrument Engineers’ Handbook by Béla G. Lipták, Process Control Instrumentation Technology by Curtis D. Johnson.

- Online courses from platforms like Coursera, Udemy, or LinkedIn Learning.

- Focus on Practice:

- Allocate at least 40% of your time to hands-on work. Theory without practice will not yield strong results.

- Track Your Progress:

- Maintain a log of the topics covered and practical tasks completed.

- Regularly evaluate your improvement through tests or real-world application.

By following this weekly plan consistently, you will build a strong foundation in instrumentation and automation, preparing you for complex tasks and career advancement in the field.