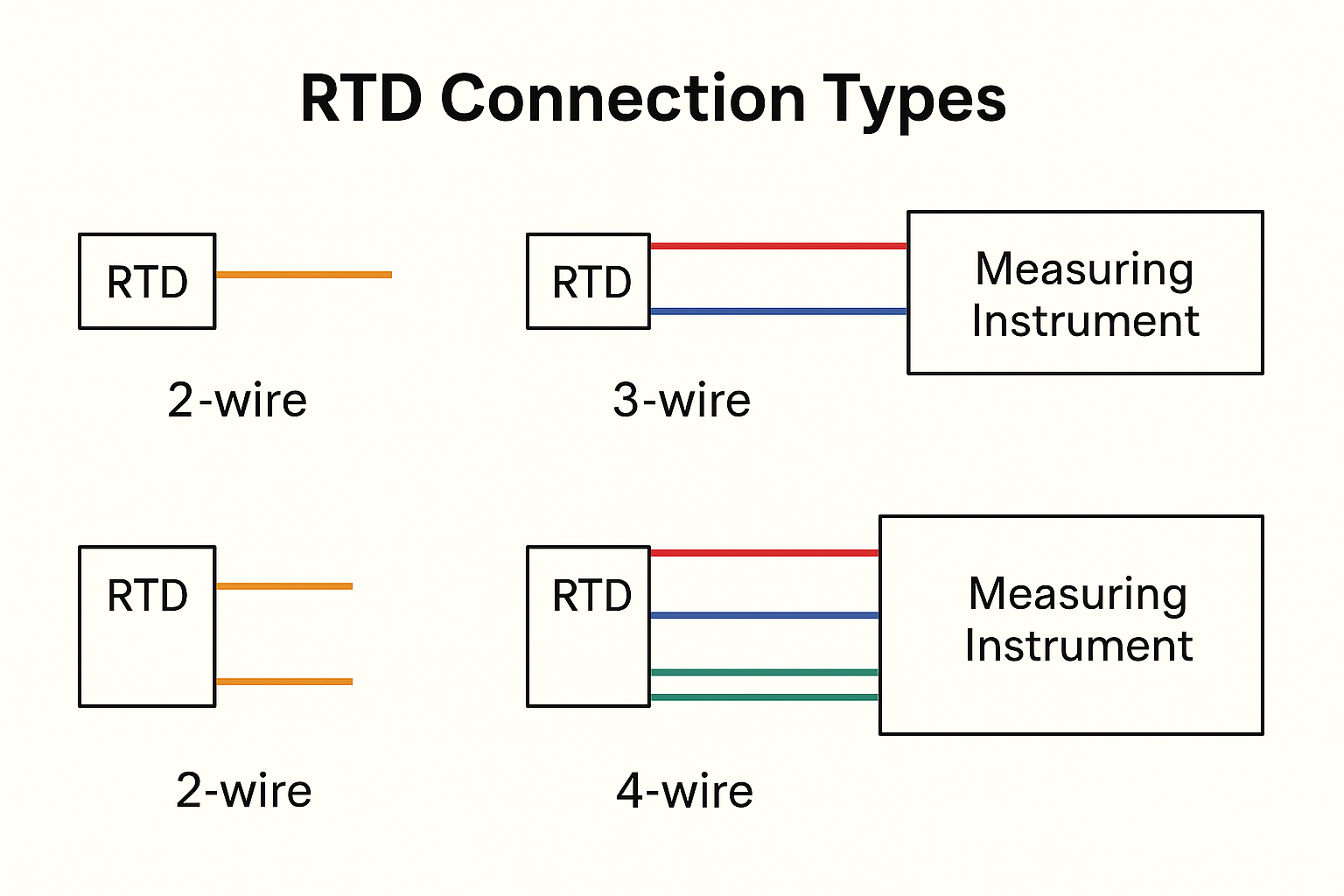

Resistance Temperature Detectors (RTDs) are widely used in industrial and laboratory environments for accurate temperature measurement. However, their wiring configuration plays a crucial role in ensuring measurement accuracy. The three main wiring types—2-wire, 3-wire, and 4-wire—differ in complexity, cost, and precision.

1. 2-Wire RTD Connection

In a 2-wire configuration, one lead wire is connected to each end of the RTD element.

Working principle: The total measured resistance equals the RTD resistance plus the resistance of both lead wires.

Pros:

Simple wiring

Lowest installation cost

Cons:No compensation for lead wire resistance

Measurement errors increase with cable length

Typical applications: Short-distance installations or systems where high accuracy is not critical.

2. 3-Wire RTD Connection

The 3-wire configuration is the most commonly used in industrial process control. Here, one end of the RTD is connected to two identical wires, and the other end to a single wire.

Working principle: The measuring instrument uses a Wheatstone bridge circuit to automatically compensate for the resistance of the lead wires, assuming the two same-end wires have equal resistance.

Pros:

Significantly reduces lead wire resistance errors

Widely supported by PLCs, DCS, and transmitters

Cons:Compensation accuracy depends on the uniformity of the wires

Typical applications: Industrial temperature measurement with moderate-to-high accuracy requirements.

3. 4-Wire RTD Connection

The 4-wire configuration offers the highest measurement accuracy. Two wires carry the measurement current, and the other two sense the voltage across the RTD element.

Working principle: The voltage-sensing wires do not carry current, so the measurement is unaffected by the resistance of the lead wires.

Pros:

Completely eliminates lead wire resistance influence

Ideal for long cable runs or high-precision measurement

Cons:Highest installation cost and wiring complexity

Typical applications: Laboratory calibration, high-precision process control, and quality inspection systems.

Comparison Table

| Wiring Type | No. of Wires | Lead Resistance Compensation | Accuracy | Cost | Common Usage |

|---|---|---|---|---|---|

| 2-wire | 2 | None | Low | Low | Short-distance, low-accuracy |

| 3-wire | 3 | Partial (bridge compensation) | Medium | Medium | Industrial standard |

| 4-wire | 4 | Full (Kelvin connection) | High | High | Laboratory, calibration |

How to Choose the Right RTD Wiring

For low-cost, short-run installations → 2-wire is acceptable.

For industrial automation → 3-wire is the most practical balance between cost and accuracy.

For laboratory or metrology work → 4-wire is the best choice.