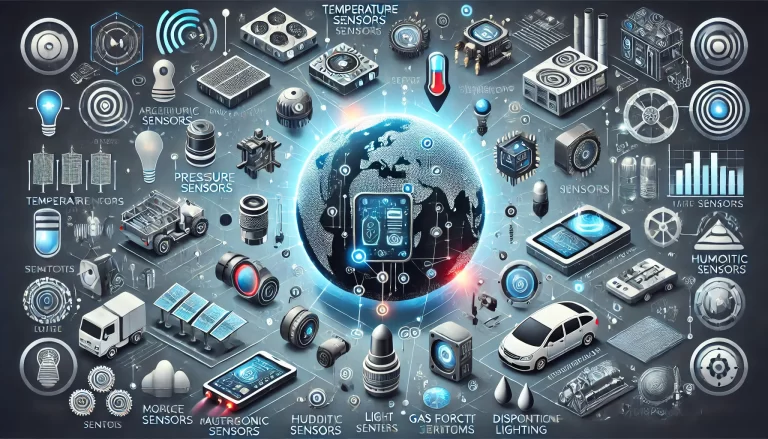

Sensors play an integral role in today’s world, providing essential data that enables various technologies to operate efficiently and intelligently. From your smartphone to industrial machinery, sensors detect and respond to different physical, chemical, and biological phenomena. In this article, we’ll delve into the ten most common types of sensors, explaining their functions, working principles, and real-world applications.

1. Temperature Sensors

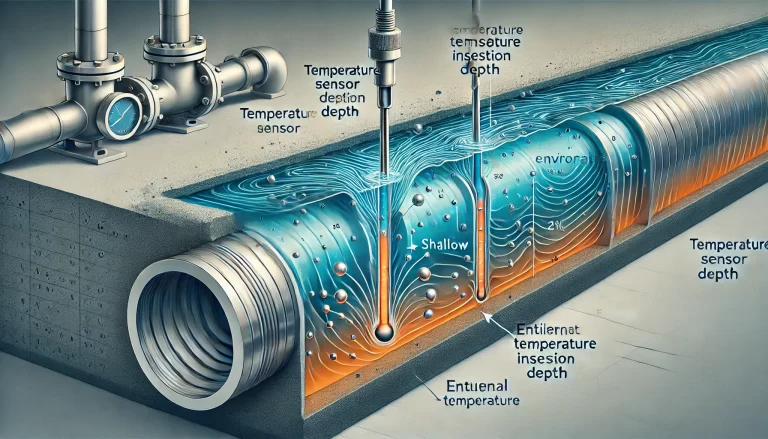

Temperature sensors are devices used to measure temperature, either of the environment or an object. There are several types of temperature sensors, including thermocouples, thermistors, resistance temperature detectors (RTDs), and infrared sensors.

- Thermocouples measure temperature through the voltage difference created when two different metals are joined together.

- Thermistors change resistance with temperature fluctuations.

- RTDs use the principle that the electrical resistance of a metal changes with temperature.

- Infrared sensors detect the thermal radiation emitted by objects.

Applications: Temperature sensors are used in a wide range of fields, such as HVAC systems, automotive engines, medical devices (thermometers), and industrial furnaces.

2. Pressure Sensors

Pressure sensors measure the force exerted by a fluid (liquid or gas) on a surface. These sensors typically convert pressure into an electrical signal for measurement. They can be capacitive, piezoresistive, or optical.

- Capacitive pressure sensors work by detecting changes in capacitance when pressure deforms a diaphragm.

- Piezoresistive sensors measure pressure through resistance changes in materials when they are subjected to pressure.

- Optical pressure sensors use light to detect pressure changes in materials.

Applications: Pressure sensors are commonly found in automotive systems (tire pressure monitoring, oil pressure measurement), aerospace, weather stations (barometers), and medical equipment (blood pressure monitors).

3. Accelerometers

Accelerometers measure acceleration forces, both static (like gravity) and dynamic (caused by movement or vibration). These sensors usually operate using piezoelectric materials or capacitive plates.

- Piezoelectric accelerometers generate an electric charge when subjected to acceleration forces.

- Capacitive accelerometers detect changes in the capacitance between two plates that move with acceleration.

Applications: Accelerometers are used in smartphones (to detect screen orientation), fitness trackers (to count steps), automotive airbags, gaming controllers, and industrial machinery for vibration monitoring.

4. Light Sensors

Light sensors detect the intensity or presence of light and convert it into an electrical signal. Common types include photodiodes, phototransistors, and light-dependent resistors (LDRs).

- Photodiodes convert light into a current based on the photoelectric effect.

- Phototransistors are similar but provide higher amplification.

- LDRs change their resistance depending on the light intensity.

Applications: Light sensors are widely used in automatic lighting systems, smartphones (to adjust screen brightness), cameras, and solar energy systems.

5. Humidity Sensors

Humidity sensors measure the moisture content in the air. These sensors often use capacitive or resistive sensing techniques.

- Capacitive humidity sensors measure the change in capacitance caused by moisture absorption in a dielectric material.

- Resistive humidity sensors detect changes in the electrical resistance of materials as they absorb water vapor.

Applications: Humidity sensors are essential in weather stations, HVAC systems, greenhouses, and devices for food storage and packaging.

6. Ultrasonic Sensors

Ultrasonic sensors measure distance or detect objects by emitting sound waves and detecting their reflection. They operate using piezoelectric materials to generate sound waves and listen for their return.

- Piezoelectric transducers convert electrical energy into sound waves and vice versa.

- Time-of-flight measurement calculates the time taken for the sound waves to return, determining the distance to an object.

Applications: Ultrasonic sensors are used in automotive parking systems, industrial robots for object detection, water level measurement, and medical imaging (ultrasound).

7. Gas Sensors

Gas sensors detect and measure the concentration of gases in the environment. Different sensors target specific gases, such as carbon dioxide (CO2), methane (CH4), or carbon monoxide (CO). These sensors often work based on chemical reactions that alter the electrical characteristics of a material.

- Electrochemical sensors detect gas through redox reactions that change electrical currents.

- Metal oxide semiconductors (MOS) detect gases by changing their conductivity when exposed to certain gases.

Applications: Gas sensors are crucial in industrial safety systems, air quality monitoring, gas leak detection, and household safety devices like carbon monoxide detectors.

8. Magnetic Sensors

Magnetic sensors measure magnetic fields, whether from permanent magnets or Earth’s magnetic field. Types include Hall effect sensors, magnetoresistive sensors, and fluxgate sensors.

- Hall effect sensors detect the voltage produced by a magnetic field perpendicular to an electric current.

- Magnetoresistive sensors measure changes in electrical resistance due to the presence of a magnetic field.

Applications: Magnetic sensors are used in compasses, automotive sensors (for ABS braking systems), smartphones (for orientation and navigation), and industrial machines to monitor rotating parts.

9. Force Sensors

Force sensors measure the magnitude of force applied to an object. These sensors are often based on strain gauges or piezoelectric materials.

- Strain gauges measure the deformation (strain) of a material when subjected to a force, converting it into a change in electrical resistance.

- Piezoelectric force sensors generate electrical signals in response to applied force.

Applications: Force sensors are widely used in weighing systems (scales), robotics (grip force detection), industrial machinery, and in medical devices to monitor patients’ physical exertion.

10. Displacement Sensors

Displacement sensors measure the distance moved by an object or its position relative to a reference point. These sensors can be optical, capacitive, or inductive.

- Optical displacement sensors use light to measure position changes.

- Capacitive displacement sensors measure changes in capacitance as the object moves.

- Inductive displacement sensors detect changes in inductance due to movement.

Applications: Displacement sensors are used in CNC machines, robotics, automotive systems (suspension systems), and industrial automation for precise positioning.

Conclusion

Sensors are the backbone of modern technological advancements, enabling devices to interact with the physical world in intelligent ways. Each type of sensor serves a specific purpose, whether it’s detecting motion, pressure, light, or other environmental factors. As sensor technology continues to evolve, we can expect even more sophisticated applications, driving innovations in fields ranging from healthcare to robotics and beyond.