In industrial production, the safe and stable operation of steam pipelines is crucial. A key component in ensuring proper system functionality is selecting the right pressure transmitter. With the variety of products available in the market, it is essential to choose a pressure transmitter that meets specific operational needs. This article provides an in-depth analysis of the factors to consider when selecting a pressure transmitter for steam pipelines and discusses the significance of choosing an appropriate capillary tube to ensure long-term, stable operation.

Key Considerations for Selecting a Steam Pipeline Pressure Transmitter

When selecting a pressure transmitter for steam pipelines, the following factors must be considered:

- Local Minimum Temperature: The temperature in the region where the pipeline is located.

- Steam Temperature: The operating temperature of the steam in the pipeline.

- Cost and Maintenance: Balancing the upfront cost with long-term maintenance requirements.

- Silicone Oil Temperature Resistance: Ensuring the silicone oil used in the pressure transmitter can withstand the high steam temperatures.

Specific guidelines include:

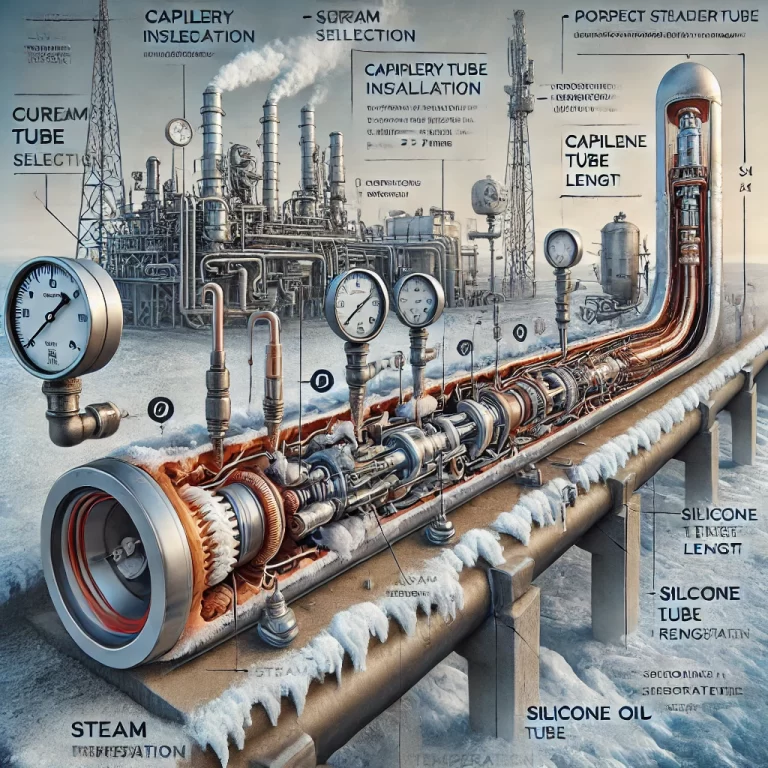

- For Steam Below 0.2 MPa (Saturated Steam Temperature of 133.5°C): A direct flange installation (usually with a transmitter rated for temperatures below 120°C) may be appropriate. For higher steam temperatures, using a capillary tube flange installation is recommended.

- For Higher Steam Temperatures: When the steam temperature exceeds what the silicone oil can tolerate, a pressure conduit installation should be considered.

- If Pressure Conduits Are Used: The design and installation should ensure the conduits are as short as possible to avoid the need for additional heating in cold climates. If condensation tanks are used with longer conduits and the local temperature drops below freezing, heating should be added.

When comparing capillary tubes to pressure conduits:

- For Low Pressures (e.g., 150 lb): The price difference between the two options is minimal. However, for higher pressures, capillary tubes tend to be more expensive but easier to maintain than pressure conduits, which require more complex maintenance.

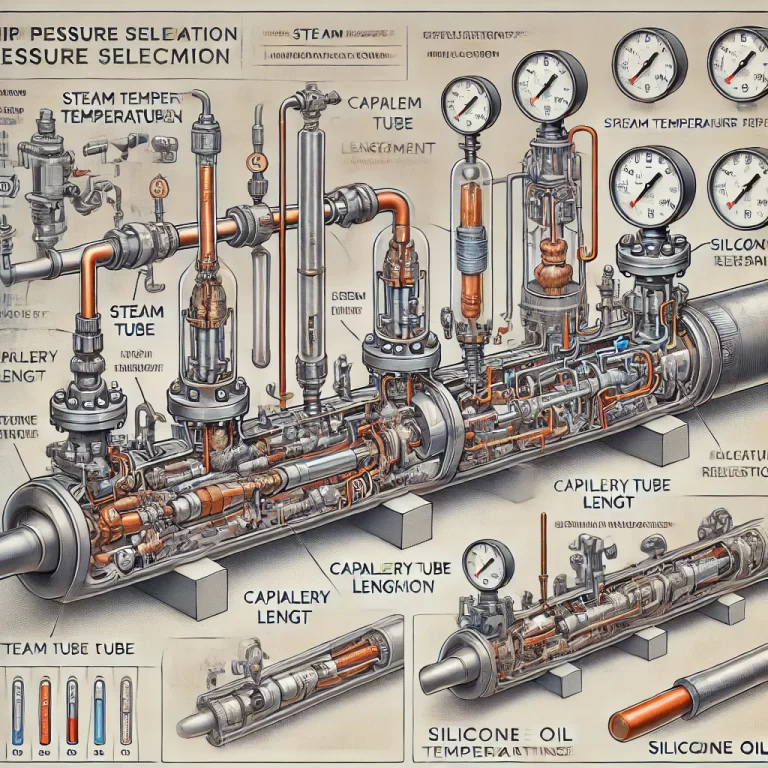

How to Select a Capillary Tube

Choosing a capillary tube involves following certain standards, such as SH/T 3005, HG/T 20507, HG/T 20515, and SH/T 3021:

- The silicone oil used should be suitable for the local minimum temperature.

- The length of the capillary tube should be kept as short as possible, considering the layout of the equipment and pipeline.

Selecting the Right Diaphragm/Capillary Tube Filling Fluid

Considerations for selecting filling fluid include:

- The local minimum temperature.

- Manufacturer specifications regarding suitable fluids.

Additional Considerations

According to SH/T 3104, capillary tubes used in pressure instruments should not exceed 15 meters in length. Additionally, the tubes should be secured with angle steel to prevent mechanical damage. In environments where the ambient temperature is lower than the freezing point of the filling oil, insulation and heating measures should be taken to avoid operational issues during winter.

Several past projects encountered problems due to the use of inappropriate silicone oil, excessively long capillary tubes, and insufficient insulation or heating during winter, leading to performance issues.

By carefully considering these factors, choosing the correct pressure transmitter and capillary tube for steam pipeline applications can significantly improve system stability and reduce maintenance challenges in cold environments.