Process control is a vital aspect of industrial operations, where the precise regulation of various parameters ensures safety, efficiency, and product quality. Among the many factors that can be monitored and adjusted, four parameters stand out as fundamental: flow, level, pressure, and temperature. These four are often referred to as the “big four” of process control because they directly influence the performance and outcome of nearly all manufacturing and production systems.

Let’s explore in greater detail why each of these parameters is critical in industrial processes and how they are controlled to maintain an efficient and safe operation.

1. Flow Control

Flow control refers to the regulation of the rate at which materials, typically fluids or gases, move through a system. It is essential in industries ranging from chemical processing and oil refining to food production and water treatment.

- Importance: Accurate flow control ensures that the correct volume of material is delivered to different parts of a process at the right time. Inconsistent flow rates can result in incomplete reactions, poor product quality, or even damage to equipment.

- Example: In a chemical plant, for instance, different reactants are often combined in specific proportions. A disruption in flow rate can lead to incorrect mixing ratios, which may compromise the quality of the final product or even create hazardous situations.

- Control Methods: Flow meters and valves are common devices used to measure and regulate flow. Technologies like electromagnetic, ultrasonic, or turbine flow meters provide real-time feedback, allowing operators to adjust the flow rate dynamically.

2. Level Control

Level control pertains to maintaining the desired height or volume of liquid within tanks, reservoirs, or reactors. It is an essential aspect of process control in industries such as chemical manufacturing, pharmaceuticals, and food production, where maintaining the correct liquid level is crucial for continuous operation and safety.

- Importance: If liquid levels are too high, there is a risk of overflow, which can lead to safety hazards such as spills, contamination, or equipment damage. Conversely, if levels are too low, processes may halt, leading to inefficiencies or equipment malfunctions due to “dry running.”

- Example: In a boiler system, water level control is critical to ensure there is enough water for heat exchange but not too much to prevent inefficiency or damage to the boiler.

- Control Methods: Level sensors (such as radar, ultrasonic, or float switches) continuously monitor liquid levels, and automated systems adjust valves or pumps to maintain the desired setpoints. Control systems also have safety alarms to prevent critical level deviations.

3. Pressure Control

Pressure control involves managing the force exerted by a fluid or gas within a system, which is particularly important in processes involving compressed gases, chemical reactions, or transportation of materials through pipelines.

- Importance: Maintaining the correct pressure ensures the safety of equipment and personnel. High pressure can cause pipelines, tanks, or vessels to burst, while low pressure may hinder the efficiency of the process, causing sluggish flow or system failures.

- Example: In oil refining, pressure control is crucial for maintaining the operational integrity of reactors and distillation columns. Overpressure in these systems could lead to catastrophic equipment failure, while under-pressure could slow production.

- Control Methods: Pressure sensors (such as piezoelectric or strain gauge sensors) provide real-time data, which is used to control pumps, compressors, or relief valves to maintain a stable pressure range. Safety valves are also installed to release excess pressure in case of system overloads.

4. Temperature Control

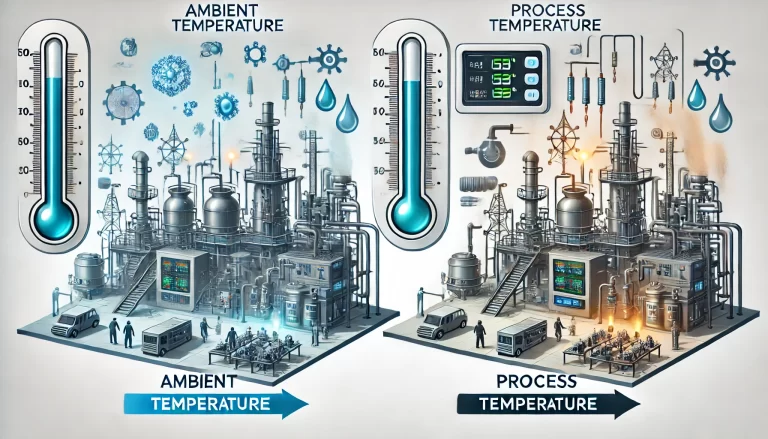

Temperature control is critical across a wide range of industries, including chemical manufacturing, metallurgy, food processing, and pharmaceuticals. Many processes are temperature-sensitive, requiring precise control to ensure product quality, reaction rates, or energy efficiency.

- Importance: Temperature affects the rate of chemical reactions, the viscosity of fluids, and the physical properties of materials. Even small deviations in temperature can lead to significant quality defects or energy losses. In some cases, such as in the handling of chemicals, improper temperature control can lead to dangerous reactions.

- Example: In chemical reactions, temperature directly influences the rate at which reactions occur. For example, in a polymerization reaction, if the temperature is too low, the reaction may proceed too slowly, resulting in low productivity. If too high, it can cause uncontrolled reactions or degradation of the product.

- Control Methods: Thermocouples, resistance temperature detectors (RTDs), and infrared sensors are commonly used to monitor temperature. Heating elements, cooling systems, and heat exchangers are then used to maintain the temperature within desired ranges. Modern control systems use feedback loops to dynamically adjust heating or cooling to match process needs.

The Interplay of Parameters

While each of these four parameters is essential on its own, they often interact in complex ways. For example, a change in flow rate can influence the pressure within a system. Similarly, variations in temperature can affect both the pressure and level in certain processes (such as in steam generation). Understanding the interplay between flow, level, pressure, and temperature is key to designing efficient and safe control systems.

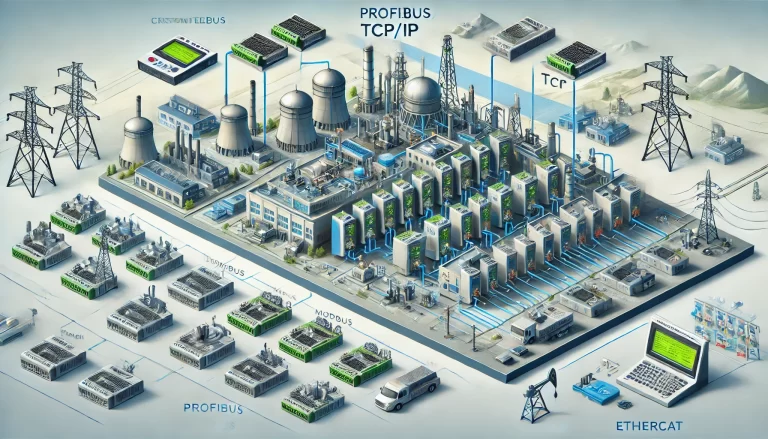

In modern industries, these parameters are typically controlled through sophisticated automation systems that use real-time data and feedback loops. Process control systems (such as Distributed Control Systems or DCS, and Programmable Logic Controllers or PLCs) continuously monitor these parameters and make adjustments as necessary to ensure the optimal functioning of the process. This ensures that operations are not only efficient but also safe and compliant with regulatory standards.

Conclusion

Flow, level, pressure, and temperature are the foundational pillars of process control in industrial operations. Their accurate monitoring and regulation are crucial for maintaining efficiency, safety, and product quality. As industries continue to adopt advanced technologies and automation, the ability to manage these parameters with precision is more important than ever. Understanding their importance and how they interact in various systems allows engineers and operators to optimize processes, prevent failures, and ensure smooth, continuous production.