In various industrial and scientific contexts, understanding the distinction between ambient temperature and process temperature is crucial. These two terms refer to different temperature measurements, each playing a distinct role in the operation, performance, and safety of equipment and processes. Here’s a detailed breakdown of the differences and their respective importance.

What is Ambient Temperature?

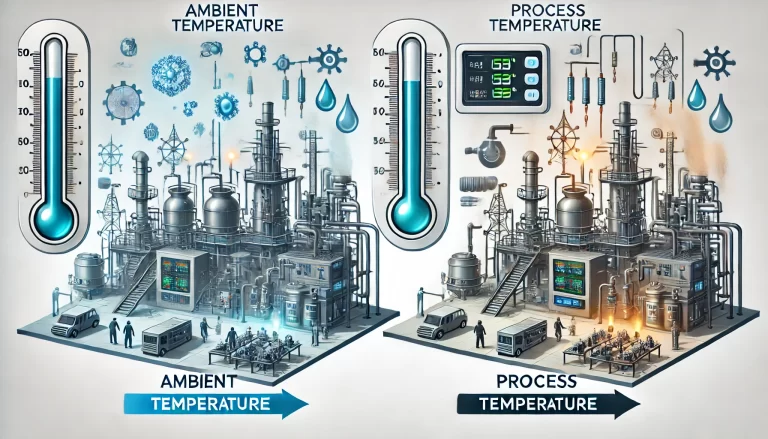

Ambient temperature refers to the temperature of the surrounding environment in which a device, system, or material operates. It’s essentially the air temperature around the object or within a specific area.

Natural vs. Controlled Environment: Ambient temperature can be measured in both outdoor and indoor settings. For instance, outdoor ambient temperature is affected by weather conditions such as sunlight, humidity, and wind. In indoor environments, ambient temperature may be controlled by air conditioning or heating systems to create a stable environment for machines or experiments.

Effects on Equipment: The ambient temperature can influence the performance and longevity of many devices. For example, electrical equipment might overheat if the ambient temperature is too high, especially in poorly ventilated spaces. Many devices are designed to operate within specific ambient temperature ranges, and exceeding these limits can result in failure or diminished performance.

Relevance in Scientific Experiments: In laboratory settings, ambient temperature needs to be monitored and controlled in sensitive experiments because fluctuations can introduce unwanted variability, affecting results.

Impact on Human Comfort and Safety: Ambient temperature is also significant in areas involving human activity. For instance, in workplaces, it is important for maintaining a comfortable environment for employees. In extreme conditions, improper control of ambient temperature can lead to health risks such as heatstroke or hypothermia.

What is Process Temperature?

Process temperature refers to the temperature of a material, fluid, or system within an operational or manufacturing process. This temperature is critical in a wide variety of industries, such as chemical engineering, food production, pharmaceuticals, and mechanical systems.

Defined by the Process: The process temperature is often dictated by the specific requirements of the operation. For example, in a chemical reactor, the temperature needs to be carefully controlled to ensure optimal reaction rates and avoid hazardous conditions. Similarly, in food processing, the temperature must be regulated to ensure proper cooking, sterilization, or preservation.

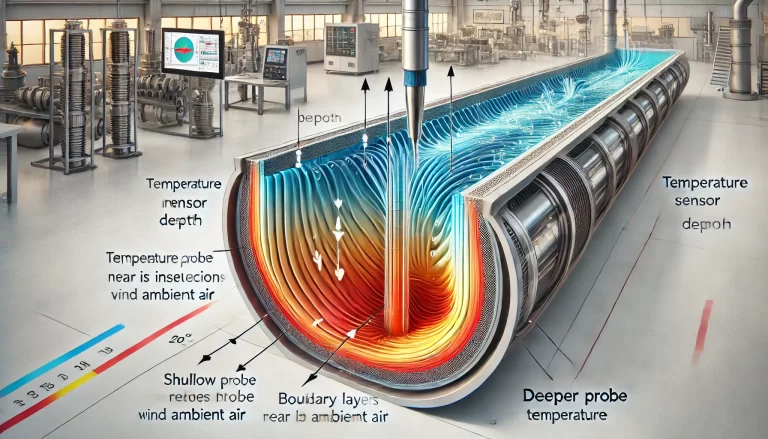

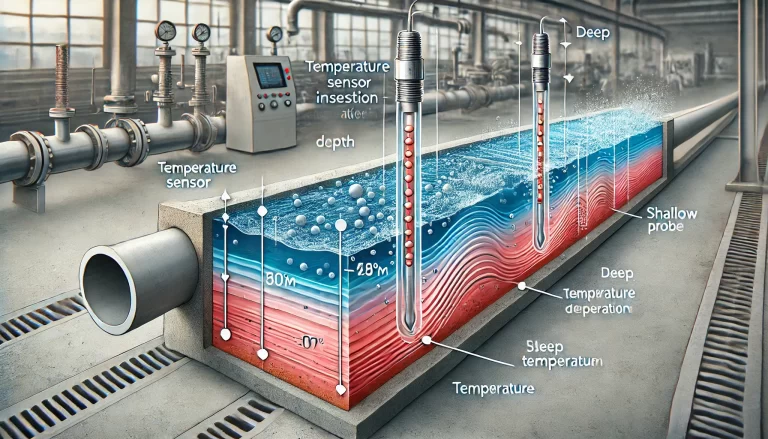

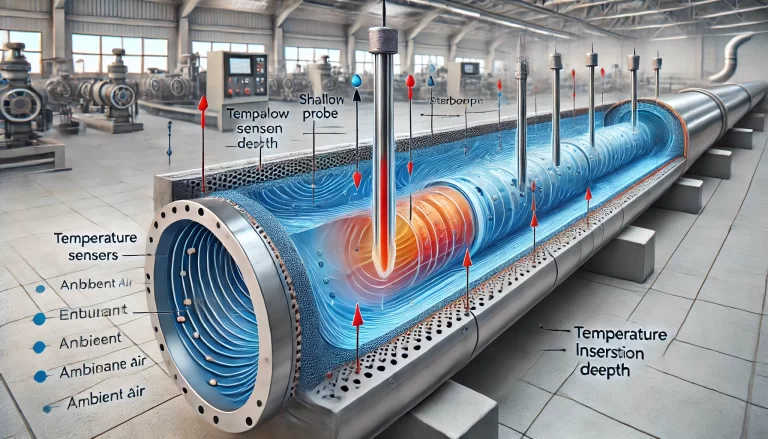

Active Monitoring and Control: Unlike ambient temperature, which is typically a passive environmental condition, process temperature is something that requires active monitoring and control. Industrial sensors and thermostats are commonly used to track process temperature, with automated systems making adjustments to keep the process within a desired range.

Importance in Quality and Safety: In many industrial operations, the process temperature is a critical factor in determining the quality of the final product. For example, in the pharmaceutical industry, specific drugs require precise temperature conditions during manufacturing to maintain efficacy and safety. In the petrochemical industry, the refining of crude oil into different products like gasoline or diesel involves multiple processes, each with its own ideal temperature range.

Energy Efficiency: Maintaining proper process temperature is also essential for energy efficiency. If a process is run at too high a temperature, it can waste energy and resources. Conversely, running at too low a temperature might slow down production or result in incomplete chemical reactions, further wasting time and energy.

Key Differences

Measurement Context: Ambient temperature is measured in the air surrounding equipment, whereas process temperature is measured within the operational medium (e.g., liquid, gas, or solid) that is undergoing the process.

Impact on Operations: Ambient temperature affects the environment in which machines and processes operate. In contrast, process temperature directly affects the operational efficiency and outcome of the process itself.

Control and Stability: While ambient temperature might be subject to natural fluctuations (especially in outdoor environments), process temperature is more rigorously controlled because it directly influences the functionality and safety of processes.

Why Both Temperatures Matter

In many cases, ambient temperature can indirectly influence process temperature. For example, if a machine is operating in a hot environment, the cooling systems or thermostats might need to work harder to maintain the desired process temperature. If the ambient temperature is too high, it can strain the cooling systems, resulting in overheating or reduced efficiency.

This relationship underscores the importance of balancing both temperatures. In industrial settings, it’s crucial to not only monitor the process temperature but also to maintain the ambient temperature within a suitable range to support the equipment’s optimal functioning.

Additionally, in some situations, special environments are created to maintain ideal ambient temperatures for delicate processes. For example, clean rooms in pharmaceutical production have tightly controlled air temperatures, humidity levels, and pressure to prevent contamination and ensure that process temperatures can be precisely regulated.

Conclusion

While ambient temperature and process temperature serve different purposes, both are vital in the design, operation, and maintenance of systems across various industries. Ambient temperature reflects the surrounding conditions in which a device or system operates, while process temperature is integral to the functioning and success of the process itself. By understanding and managing both, industries can ensure efficiency, safety, and the longevity of their equipment and products.