Addressing High Temperature, High Humidity, Heavy Rainfall, and Lightning Conditions

1. Environmental Protection: Coping with Summer Hazards

1.1 Heat Dissipation and Temperature Control

Inspect cooling components such as fans and ventilation grilles in control cabinets; clean dust, plant debris, or insects that may block airflow.

Avoid direct sunlight exposure on instruments; install sunshades or reflective insulation. For high-temperature zones (e.g., near furnaces or steam lines), use air conditioning or forced-air cooling to maintain device temperature within rated limits (typically -20°C to 60°C).

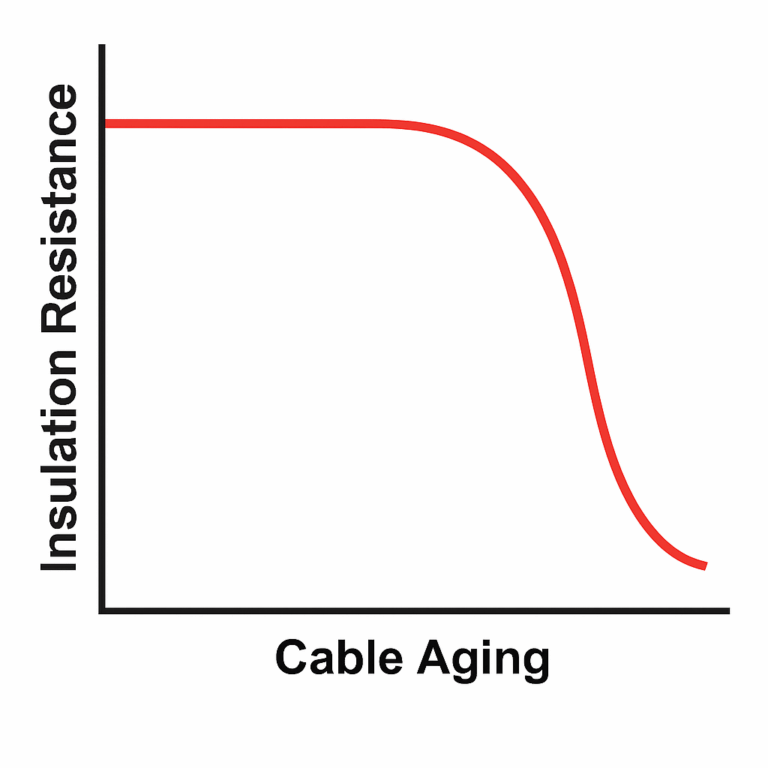

Monitor terminal blocks and cables: Check for insulation aging, discoloration, or loosening caused by heat. Consider adding heat sinks or isolating heat-sensitive wires.

1.2 Moisture and Water Ingress Protection

Inspect seals and enclosures: Replace aging O-rings or cracked gaskets in junction boxes and transmitters. Ensure rain hoods and waterproof connectors are in good condition.

Install desiccants and dehumidifiers inside cabinets; in humid environments, use heating plates to prevent condensation.

Maintain drainage systems near installation areas to avoid ponding or immersion. Instruments in low-lying areas should be elevated or protected with waterproof barriers.

1.3 Lightning and Surge Protection

Check lightning protection systems: Verify condition of lightning rods and Surge Protective Devices (SPD). Test ground resistance (typically ≤4Ω); clean rust from grounding terminals.

Protect signal transmission lines: Shield and ground all outdoor signal cables properly. Use signal isolators or lightning arrestors as needed.

2. Device Maintenance: Focused Inspection and Servicing

2.1 Key Component Checks

Sensors and transmitters: Clean dust or scale from sensor probes. For transmitters, verify 4–20mA outputs are stable and not drifting due to heat.

Actuators and valves: Check for aging of seals and lubricant breakdown. Use high-temp grease where necessary.

Display and communication: Inspect HMI screens for blackouts or flickering; verify RS485/Profibus connectivity is intact.

2.2 Electrical System Reliability

Power stability: Measure supply voltage; ensure within ±10% of rated value. Test UPS and backup battery life (which degrades in heat).

Insulation resistance: Use insulation testers (≥50MΩ is ideal); tighten terminal screws to prevent false alarms due to loose contacts.

2.3 Calibration and Precision Assurance

Seasonal calibration plan: Increase calibration frequency in summer (e.g., monthly). For temperature and pressure sensors, reverify accuracy and recalibrate if error exceeds ±0.5% FS.

Function test: Run manual/auto switching checks for control valves and flowmeters to detect mechanical sticking or signal delays.

3. Inspection and Emergency Management

3.1 Routine Patrol and Monitoring

Use daily inspection checklists: Include external temperature (≤50°C), display accuracy, alarm records, power status, ambient humidity.

Tag key instruments in high-risk zones (e.g., reactor thermometers, vessel pressure transmitters) for increased inspection frequency.

3.2 Spare Parts and Response Preparedness

Stock essential parts (sensors, O-rings, fuses) in dry, ventilated areas. Periodically power on spare instruments to ensure readiness.

Establish emergency procedures for common faults (e.g., thermal shutdown, lightning damage) with clear steps: power cut, instrument switchover, temporary calibration.

4. Safe Work Practices and Personnel Management

4.1 Safe Maintenance in Hot Environments

Provide breathable PPE, cooling kits, and hydration supplies to technicians. Avoid peak heat hours during outdoor work.

For confined spaces (e.g., instrument pits), pre-ventilate and monitor O₂ concentration (≥19.5%).

For electrical work, ensure insulated tools are used; pre-depressurize high-pressure instruments before servicing.

4.2 Training and Documentation

Train staff on effects of heat and humidity on devices, including desiccant replacement and lightning protection checks.

Maintain detailed maintenance logs for traceability, planning, and fault root cause tracking.

5. Common Scenarios and Solutions

| Scenario | Recommended Measures |

|---|---|

| Outdoor instruments | Install sun/rain shields, fill junction boxes with waterproof gel, remove dust or nests that block airflow. |

| Humid environments | Use thermostatic heater plates (>70% RH triggers), seal cable inlets with weatherproof putty. |

| High-temperature furnace zones | Verify cooling systems (e.g., air blowers); ensure sensors (e.g., ceramic thermocouples) are rated for high heat. |

| High-lightning areas | Encase signal cables in grounded metal conduits; establish dedicated grounding for instrument systems. |

Conclusion

By integrating seasonal adaptations, routine maintenance, and emergency readiness, industries can greatly reduce the risk of summer-related instrument failures. Emphasis should be placed on preventive maintenance and responsibility management, ensuring safe and accurate instrument operation during harsh summer conditions.