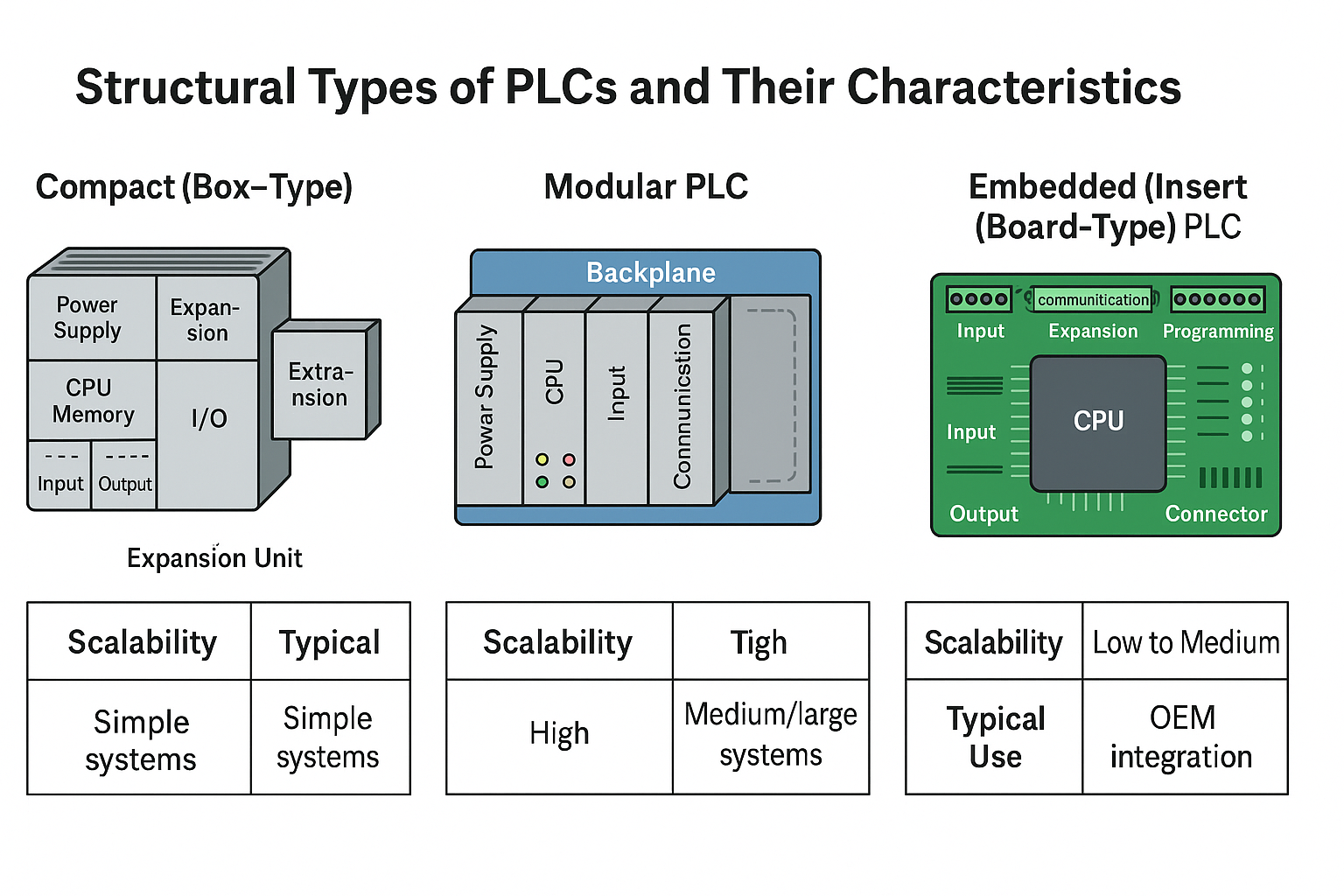

Programmable Logic Controllers (PLCs) are widely used in industrial automation for their flexibility, reliability, and scalability. Based on their physical structure and configuration, PLCs can be generally classified into three types:

Compact (Box-Type)

Modular

Embedded (Insert Board-Type)

Each type has distinct design features, advantages, and typical applications, which are outlined below.

1. Compact (Box-Type) PLC

A compact PLC integrates the essential components—power supply, CPU, memory, and I/O system—into a single enclosure. This structure is commonly used for micro and small-scale automation systems.

🔹 Key Features:

Self-contained and ready to use as a standalone control unit.

Some models support optional plug-in boards for communication, memory expansion, or analog input/output.

Expansion units can be added to increase I/O capacity if required.

🔹 Advantages:

Space-saving and cost-effective

Quick installation and easy setup

Ideal for simple or dedicated applications

🔹 Applications:

Packaging machines

Small production lines

HVAC systems

2. Modular PLC

Modular PLCs consist of separate function-specific modules that are combined to build a complete system. Typical modules include:

CPU module

Input modules

Output modules

Power supply module

Communication module

Backplane or rack

This type is commonly used in medium to large-scale industrial control systems.

🔹 Common Structural Variants:

2.1 Without Backplane (Direct Interface)

Modules connect directly through side interfaces and are mounted on a DIN rail.

Examples: OMRON CJ1, Siemens S7-300

2.2 With Fixed-Slot Backplane

All modules plug into a backplane with a fixed number of slots (e.g., 3, 5, 8, or 10).

Note: Empty slots may result in wasted space or require dummy covers.

2.3 Rack-Based Configuration

Modules are mounted into a rack, providing stronger mechanical stability. These systems may omit module enclosures but include front panels for sealing and display.

🔹 Advantages:

High scalability and flexibility

Easy to maintain and expand

Suitable for complex automation tasks

🔹 Applications:

Process automation

Large-scale production lines

Distributed control systems (DCS)

3. Embedded (Insert Board-Type) PLC

This type of PLC is designed to be embedded directly into other systems, such as CNC controllers or special machinery. It appears as a control board rather than a separate unit.

🔹 Key Features:

Includes digital input/output terminals

Provides communication, expansion, and programming ports

Offers full PLC functionality in a compact PCB format

🔹 Advantages:

Seamless integration into host devices

Compact and lightweight

Cost-effective for OEMs

🔹 Applications:

CNC machines

Smart terminals

Compact automation modules

✅ Conclusion

Understanding the structural types of PLCs is essential for selecting the right control system architecture. Here’s a quick comparison:

| Type | Structure | Scalability | Typical Use |

|---|---|---|---|

| Box-Type | All-in-one | Limited | Simple systems |

| Modular | Flexible modules | High | Medium/large systems |

| Insert Board | Embedded PCB | Low to Medium | OEM integration |

By matching the PLC structure to the specific application needs, engineers can optimize control performance, reduce costs, and enhance system reliability.