The Recurring Problem That Keeps Getting “Corrected” Year After Year

“Seal the drain holes!”

“No, open them!”

For many industrial plants, this back-and-forth has become a frustrating ritual during every inspection.

Despite repeated rectifications and compliance efforts, this “small issue” surrounding instrumentation conduit drainage continues to resurface. Why is this happening? Do the standards really say nothing definitive? Or are we misunderstanding their intent?

Let’s explore the real reasons behind this industry-wide dilemma—and how to solve it once and for all.

🔍 The Core Conflict: Water Must Be Blocked, But Also Must Be Drained

Instrument conduits are used to protect signal cables running between field devices and control systems. However, they are vulnerable to two conflicting risks:

Ingress Risk: Rainwater, condensation, or washdowns can enter open conduits, causing moisture damage and signal faults.

Trapped Water Risk: If the drain holes are sealed, any moisture that does get inside (e.g. from condensation or minor leaks) can’t escape, leading to long-term corrosion and insulation degradation.

So, should we seal them to prevent water ingress? Or leave them open to let water drain?

The real solution lies somewhere in between.

📘 What Do Standards Say?

Contrary to popular belief, this is not a gray area. Multiple global and national standards do offer clear guidance, typically recommending controlled drainage rather than permanent sealing or full exposure.

| Standard | Recommendation |

|---|---|

| GB 50093 (China) – Code for Installation of Industrial Automation Systems | Drain holes should be installed at the lowest point and must not be permanently sealed. |

| SH/T 3004 – Petrochemical Instrument Design Spec | Conduits must include drainage features to avoid water accumulation. |

| API RP 552 (USA) – Instrument Installation Guidelines | Drain points should be accessible and serviceable, ideally using removable plugs or traps. |

In short:

Drainage should be allowed—but with protection against external water ingress.

🛠 Recommended Practice: Controlled Drainage with Protection

Modern best practices suggest a balanced approach, ensuring both moisture egress and ingress protection. Here’s how:

✅ Install Downward-Facing Drain Holes

At the lowest point of the conduit, usually near junction boxes or field enclosures.

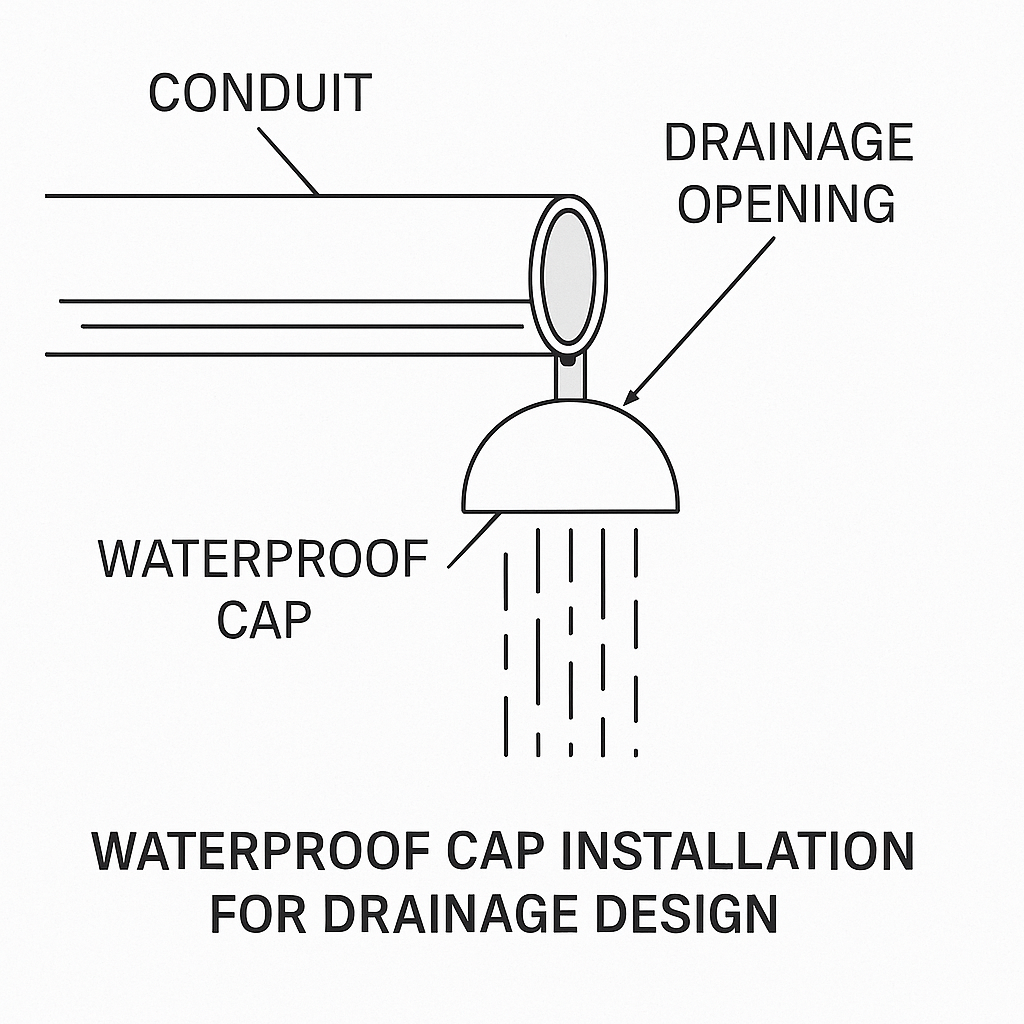

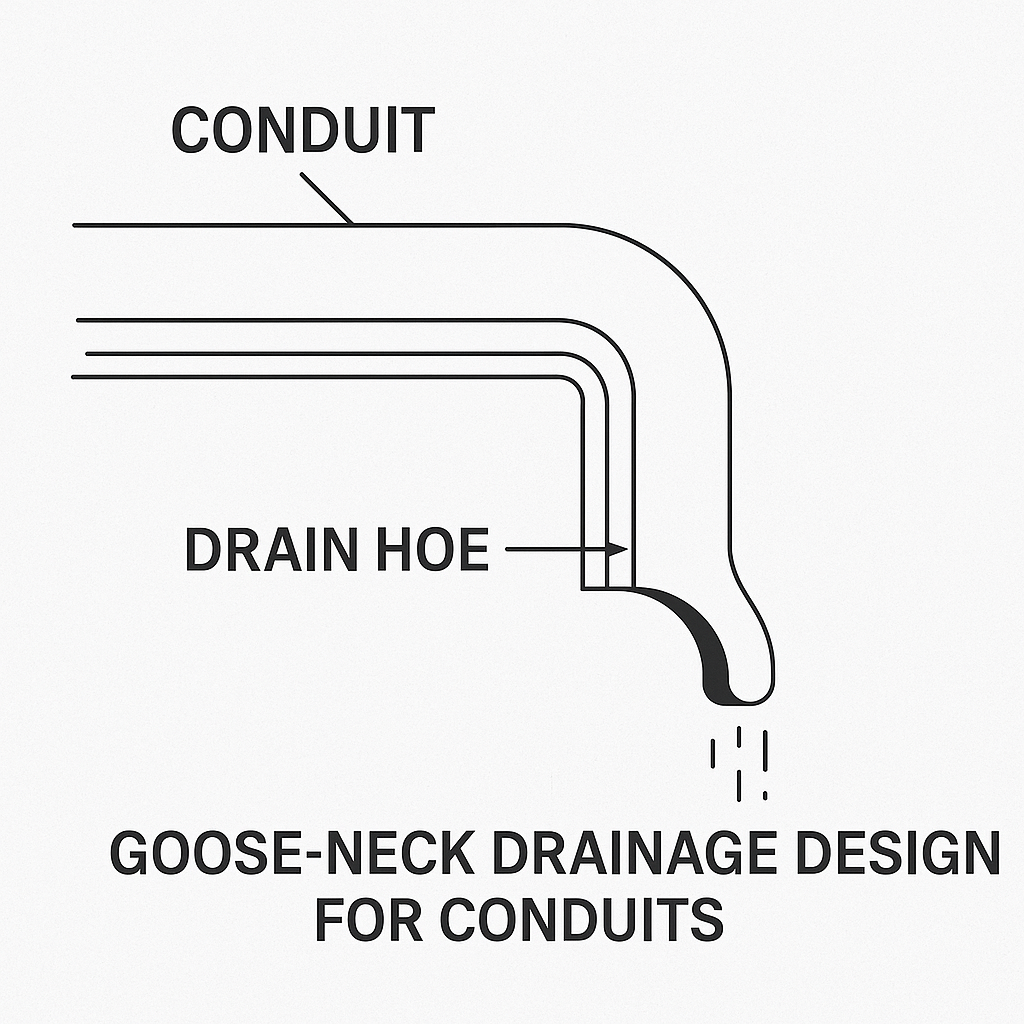

✅ Add Drip Covers or Goose-Neck Bends

These physically block external water from entering, while allowing internal moisture to escape.

✅ Use Removable Plugs or Screens

To facilitate periodic inspection and maintenance without permanent sealing.

✅ Include in Routine Inspection Plans

All drain holes should be checked, cleaned, and recorded on a regular basis.

❓ Why Does This Issue Keep Coming Back?

Despite clear technical recommendations, many sites still face recurring issues due to:

Inconsistent Interpretations

Different inspectors or contractors may offer contradictory guidance, especially in multi-phase projects.Poor Communication Between Design and Construction Teams

Drainage details are often overlooked or undocumented in drawings.No Preventive Maintenance Culture

Without regular inspection, open drain holes can become clogged—or sealed as a quick fix.Changing Personnel, Same Mistake

Knowledge gaps are passed down, and the “fix” becomes a recurring cycle.

✅ Final Takeaway: Don’t Choose Between “Open” and “Closed” — Choose “Protected”

This issue isn’t about a binary choice. The real question is:

How can we allow safe drainage while blocking hazardous ingress?

The answer lies in smart design, visual documentation, and regular maintenance.

Once you treat it as part of your system reliability—not just a compliance checkbox—you’ll stop seeing it as a headache.