In industrial safety and control systems, emergency stop (E-stop) buttons play a critical role in protecting personnel and equipment from harm in the event of an urgent situation. E-stop buttons, often featuring protective covers, are designed to halt machinery immediately when pressed. Whether or not these protective covers should be locked or sealed is a nuanced question, depending on the specific needs, environment, and risk assessment of each installation. This article discusses factors to consider regarding the decision to lock or seal emergency stop button covers.

Purpose of the Emergency Stop Button and Its Protective Cover

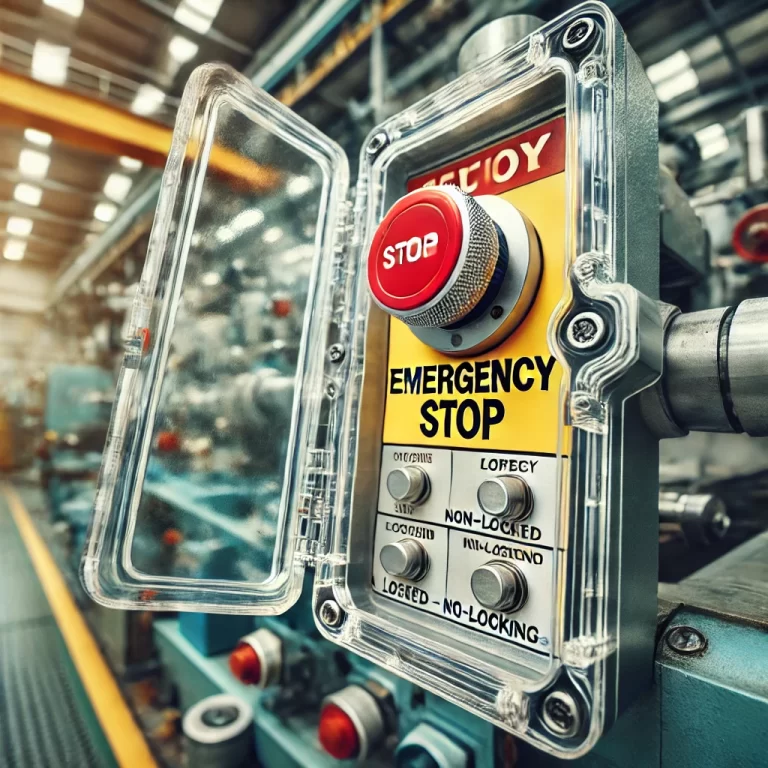

An E-stop button serves as an immediate shutdown device, typically positioned in accessible locations on machinery or in high-traffic areas where quick access is essential. The protective cover, generally a transparent or hinged shield, is intended to reduce the likelihood of accidental activation, yet still allow for easy and rapid access when necessary. In safety-critical environments, covers add a layer of protection against accidental bumps or unintended operation while ensuring the button is visible and accessible in an emergency.

Considerations for Locking or Sealing E-Stop Button Covers

Whether or not to lock or seal an E-stop button cover depends on several key considerations, including the specific risks associated with the equipment, location, frequency of use, and operational environment. Below are some factors that can guide this decision.

1. Risk of Unauthorized or Accidental Activation

- High-Risk Areas: In environments where an accidental or unauthorized press of an E-stop button could disrupt critical operations or compromise safety, it may be advisable to lock or seal the cover. Locking the cover provides an added level of control, ensuring that only trained personnel with access to the key can operate the E-stop in non-emergency situations.

- Frequent Use and Accessibility: In cases where E-stop buttons are frequently used or need to be readily accessible for authorized personnel, a locked or sealed cover may be counterproductive, as it could slow down the response time in an emergency. In such cases, a simple hinged cover without a lock may suffice.

2. Regulatory and Industry Standards

- Compliance Requirements: Certain regulatory standards may dictate whether E-stop button covers should be locked or sealed. In some industries, particularly in high-risk environments (e.g., chemical plants, heavy manufacturing), guidelines may require sealed covers to prevent tampering or accidental activation.

- Company Policies: In addition to regulatory standards, company-specific safety policies may require additional security for E-stop buttons. Consulting the company’s health and safety guidelines can provide clarity on whether a lock or seal is necessary for compliance.

3. Impact of Delayed Access During Emergencies

- Response Time: Locking or sealing a cover could introduce a slight delay in activating the E-stop button. In critical environments where immediate shutdown is necessary to prevent harm or damage, this delay could pose a safety risk. In these cases, companies often opt for covers that do not require keys or seals, allowing personnel to press the button instantly in an emergency.

- Emergency Preparedness: In environments where personnel are trained to respond quickly to emergencies, a locked cover could hinder their ability to act swiftly. An E-stop button should always be designed to provide immediate access for authorized personnel in an emergency.

4. Protective Cover Options

- Non-Locking Flip Covers: These covers provide basic protection by reducing the chance of accidental contact but do not impede access. They are a common choice for situations where quick access is crucial, but where minor accidental activation risks are acceptable.

- Lockable Covers: These are often used in environments where unauthorized access poses a significant risk. The cover can be locked during non-operational hours or in restricted areas but left unlocked during active use if rapid emergency access is required.

- Sealed Covers with Tamper-Evident Seals: In some cases, using tamper-evident seals (such as wire or plastic ties) on E-stop covers can provide a balance between security and accessibility. Seals can deter accidental activation without requiring keys to remove, and they can be broken easily during emergencies if necessary.

Best Practices for Using Locked or Sealed E-Stop Covers

Assess the Risk and Environment: Conduct a risk assessment of the machinery and location to determine the need for locking or sealing. If the machine is in a public or accessible area, or if unauthorized access is a concern, locking may be appropriate.

Consider Personnel Training: Ensure that all relevant personnel are trained on the proper use of E-stop buttons and understand how to access them in case of an emergency. Training should also cover procedures for unlocking the cover if it is locked.

Regular Safety Audits: Periodically audit the E-stop buttons and covers to confirm they are in proper working condition and that any locks or seals are functioning as intended. Regular checks ensure that safety is not compromised by inaccessible E-stop buttons due to faulty locks or seals.

Consult Industry Standards: Adhering to industry standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the International Electrotechnical Commission (IEC), ensures that E-stop buttons and covers meet recommended safety criteria.

Conclusion

The decision to lock or seal an E-stop button cover should be based on a careful evaluation of safety requirements, accessibility needs, and regulatory standards. While locked covers can prevent unauthorized use, they can also delay response times during emergencies, which may be counterproductive in certain settings. In most scenarios, ensuring that emergency stop buttons are both accessible and protected from accidental activation is the ultimate goal. Through a balanced approach that considers both safety and accessibility, companies can create a secure environment that allows personnel to respond quickly and effectively in emergency situations.