Introduction

No matter how advanced or expensive your sensor is, its performance will degrade over time.

To maintain measurement accuracy, system reliability, and compliance, regular calibration is essential.

This guide explains what sensor calibration is, why it matters, and how to build a calibration strategy that keeps your instrumentation sharp and dependable.

1. What Is Sensor Calibration?

Calibration is the process of comparing a sensor’s output with a known, traceable standard to detect and correct deviations.

In simple terms:

You apply a known input → check the output → adjust the system if needed.

Calibration ensures that what your sensor “thinks” is 100 N, 1 bar, or 50 °C… actually is.

2. Why Is Calibration Necessary?

Sensors drift over time due to:

Mechanical fatigue (strain in load cells)

Aging of electronics or components

Environmental effects (temperature, moisture)

Installation or handling errors

Shock or overload events

Without calibration, drift accumulates—causing poor product quality, failed inspections, or even unsafe conditions.

3. Key Calibration Terms

| Term | Meaning |

|---|---|

| Zero | Output with no input applied |

| Span or Gain | The relationship between input change and output change |

| Linearity | How closely the output follows a straight line across the range |

| Drift | Change in output over time without change in input |

| Traceability | Connection to a national or international standard (e.g., NIST) |

4. How Often Should You Calibrate a Sensor?

| Use Case | Recommended Frequency |

|---|---|

| Critical safety or compliance | Every 6–12 months |

| High-cycle industrial usage | Every 6 months or quarterly |

| General process monitoring | Annually |

| After impact, overload, or repair | Immediately |

👉 Always follow the sensor manufacturer’s calibration guidelines.

5. Calibration Methods

🧪 Standard Weight / Deadweight Calibration (Load Cells)

Apply known weights and record output across multiple points.

🔧 Simulated Signal Injection

Use a voltage or current simulator to check the output signal chain.

🔁 Shunt Calibration

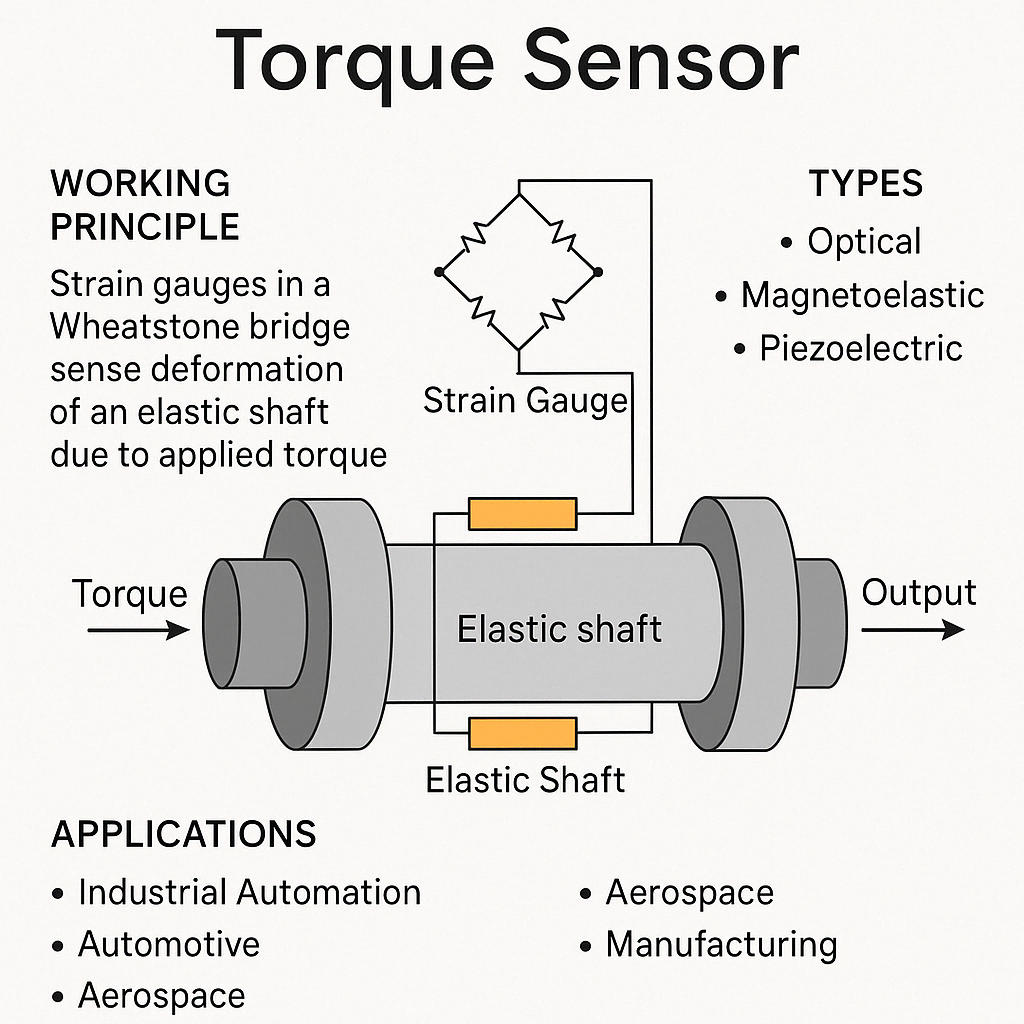

Use an electrical resistor across the Wheatstone bridge to simulate strain (for strain gauge sensors).

💻 Software Calibration (Digital Sensors)

Use manufacturer-provided tools or software to adjust digital sensors via USB, RS485, or CAN.

6. Calibration Equipment You May Need

Certified reference standards (e.g., weights, pressure gauges)

Precision multimeter or signal conditioner

Calibration fixture (jig, bracket, or test frame)

Calibration certificate templates

Environmental chamber (for temperature influence testing)

7. Best Practices for Long-Term Accuracy

✅ Use traceable standards (e.g., ISO 17025 certified weights)

✅ Calibrate under real-world conditions (same temp, load path, etc.)

✅ Allow warm-up time for sensors and electronics

✅ Record “as-found” and “as-left” data for documentation

✅ Label all calibrated sensors with date and due date

8. What Happens If You Don’t Calibrate?

Gradual loss of measurement confidence

Failed audits or certification lapses

Faulty products, wasted materials

In extreme cases: equipment damage or safety incidents

Calibration is preventive maintenance for your data.

Conclusion

Sensor calibration isn’t just a checkbox—it’s a core practice for ensuring quality, consistency, and trust in your measurements. Whether you’re operating in a high-stakes industrial plant or a precision lab, calibrating your sensors regularly pays off with better performance and fewer surprises.

Accuracy doesn’t last forever—but with calibration, it can last a lot longer.