Abstract

Real-Time Optimization (RTO), Advanced Process Control (APC), and Self-Optimizing Control (SOC) are complementary approaches in hierarchical control structures. While RTO aims to deliver economically optimal setpoints, APC translates them into feasible tactical targets, and PID controllers execute the actions. This paper reviews their interrelationship, practical boundaries, and economic feasibility, with examples from process industries.

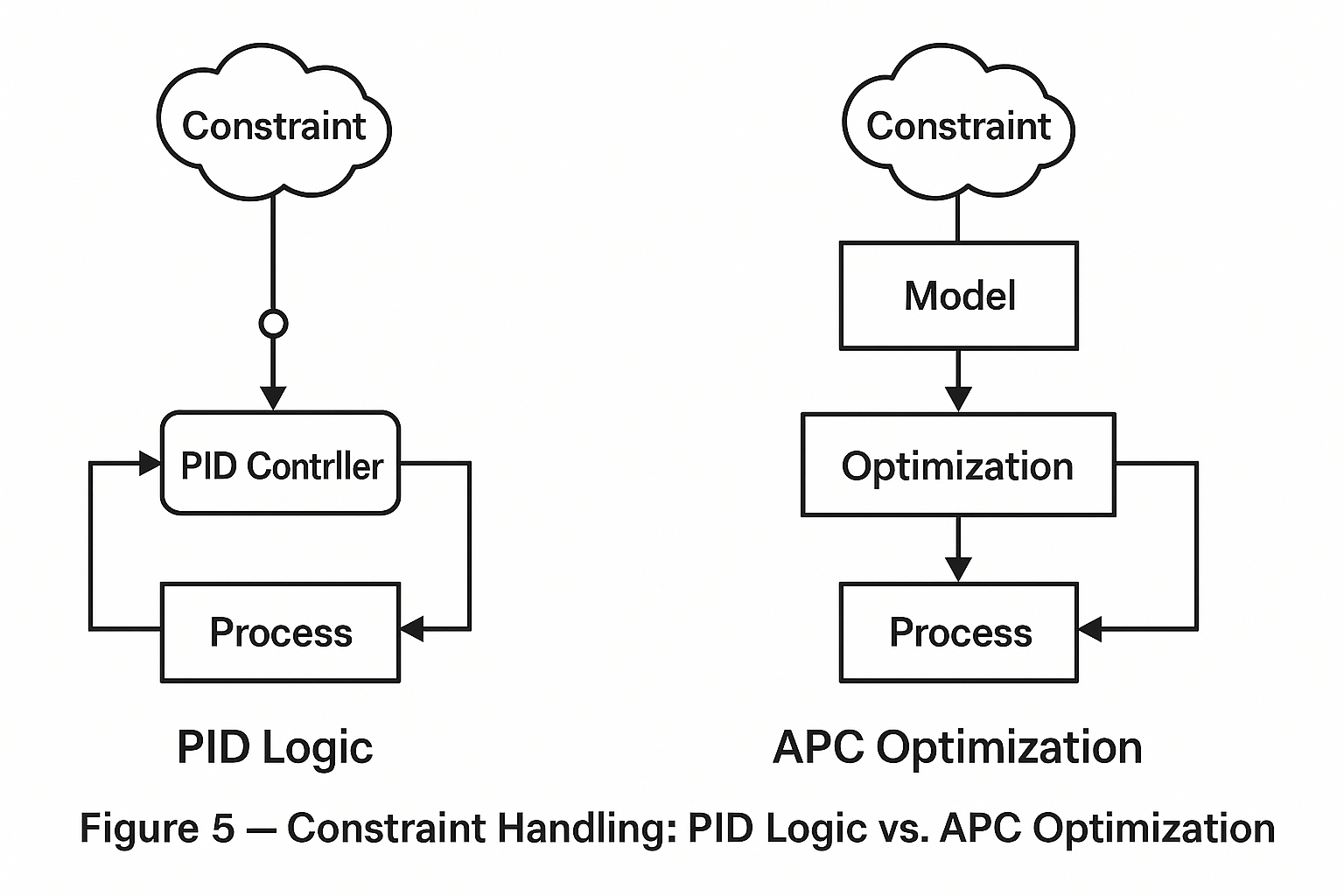

1. From PID to Logic-Based Optimization

PID controllers remain the foundation of process automation. With proper structures, PID loops can achieve certain forms of optimization through logical strategies:

Valve Position Control (VPC): Coordinates multiple manipulated variables and exploits valve degrees of freedom.

Override Control: Typical of dynamic constraint handling, ensuring safety under disturbances.

Split-Range Control: Sequential use of manipulated variables for cost or operational optimization.

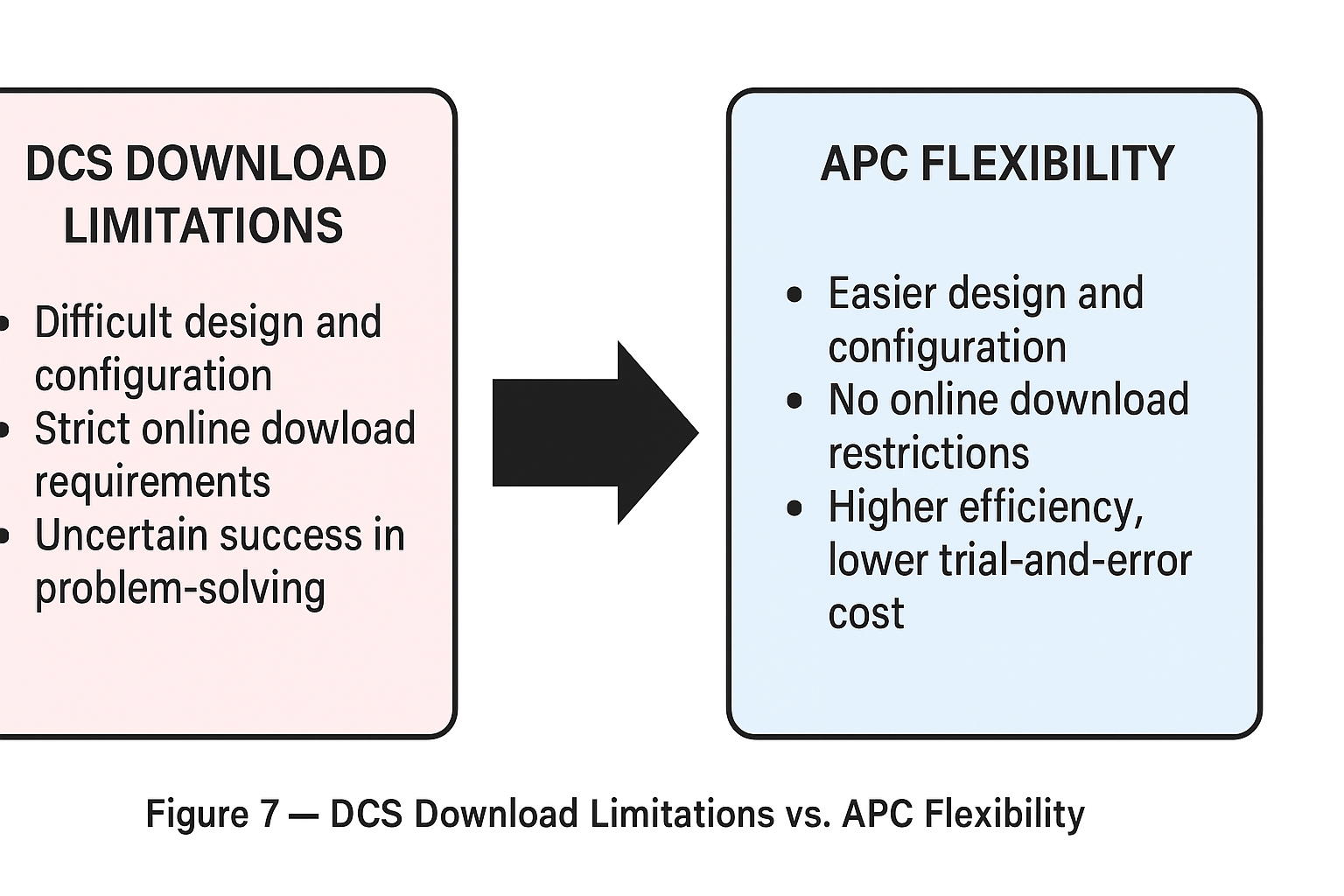

2. Advanced Process Control as the Bridge

APC has become widespread in petrochemical industries. Compared with single-loop PID, APC provides:

Unified framework for multivariable control

Lower overall cost for constraint handling

Capability for wide-range coordination (columns, trains, or entire plants)

In hierarchical structures, APC operates at the minutes scale, adjusting PID setpoints.

However, APC has limitations:

Large-scale linear optimization (e.g., scheduling) becomes computationally intensive.

Nonlinear models with inflection or saddle points cannot be solved efficiently with simple linearization.

3. Real-Time Optimization in Context

RTO emerged to bridge economics and control when higher-frequency mechanistic optimization was impractical.

Hourly-scale RTO: Uses steady-state models to update optimal targets.

When not needed: If processes remain at boundaries or if cost-benefit ratio is low, RTO may be skipped.

Practical role: Sits above APC, focusing on steady-state economics, while APC ensures dynamic feasibility and safety.

4. Self-Optimizing Control (SOC)

Proposed by Sigurd Skogestad (2000), SOC designs controlled variables to achieve economic optimality without explicit RTO layers.

Key ideas:

Optimization embedded in variable selection and structure.

RTO and APC become less critical if SOC is well-designed.

Recent works (Ye Lingjian, 2023) demonstrate SOC’s expanding application in chemical industries.

5. Discussion and Practical Insights

Economics vs. feasibility: If PID/logic suffices, higher-level APC or RTO may not be cost-effective.

Strategic vs. tactical: RTO provides strategic objectives, APC translates them into tactical setpoints, PID executes locally.

Technology evolution: RTO was limited by computation and modeling gaps; APC became dominant due to practicality.

Future outlook: With faster computation and dynamic models, high-frequency RTO may eventually merge with APC.

6. Conclusion

RTO, APC, and SOC are not mutually exclusive but complementary.

RTO focuses on strategic optimization at slower timescales.

APC ensures dynamic feasibility and safety while transmitting optimal targets.

PID provides local stability and fast execution.

SOC offers a paradigm shift, embedding optimization into control variable design.

The effectiveness of a hierarchical control system depends not on the existence of every layer, but on whether each layer translates higher-level objectives into feasible and safe lower-level actions.