Abstract

Pneumatic conveying is a widely used method for transporting powders and granular materials in modern industries. By using compressed air as the driving force, it enables efficient, dust-free, and flexible material handling over long distances. This article introduces the basic principles, pressure requirements, pressure loss mechanisms, causes of fluctuations, vessel pressure behavior, and industrial applications of pneumatic conveying systems.

1. What Is Pneumatic Conveying?

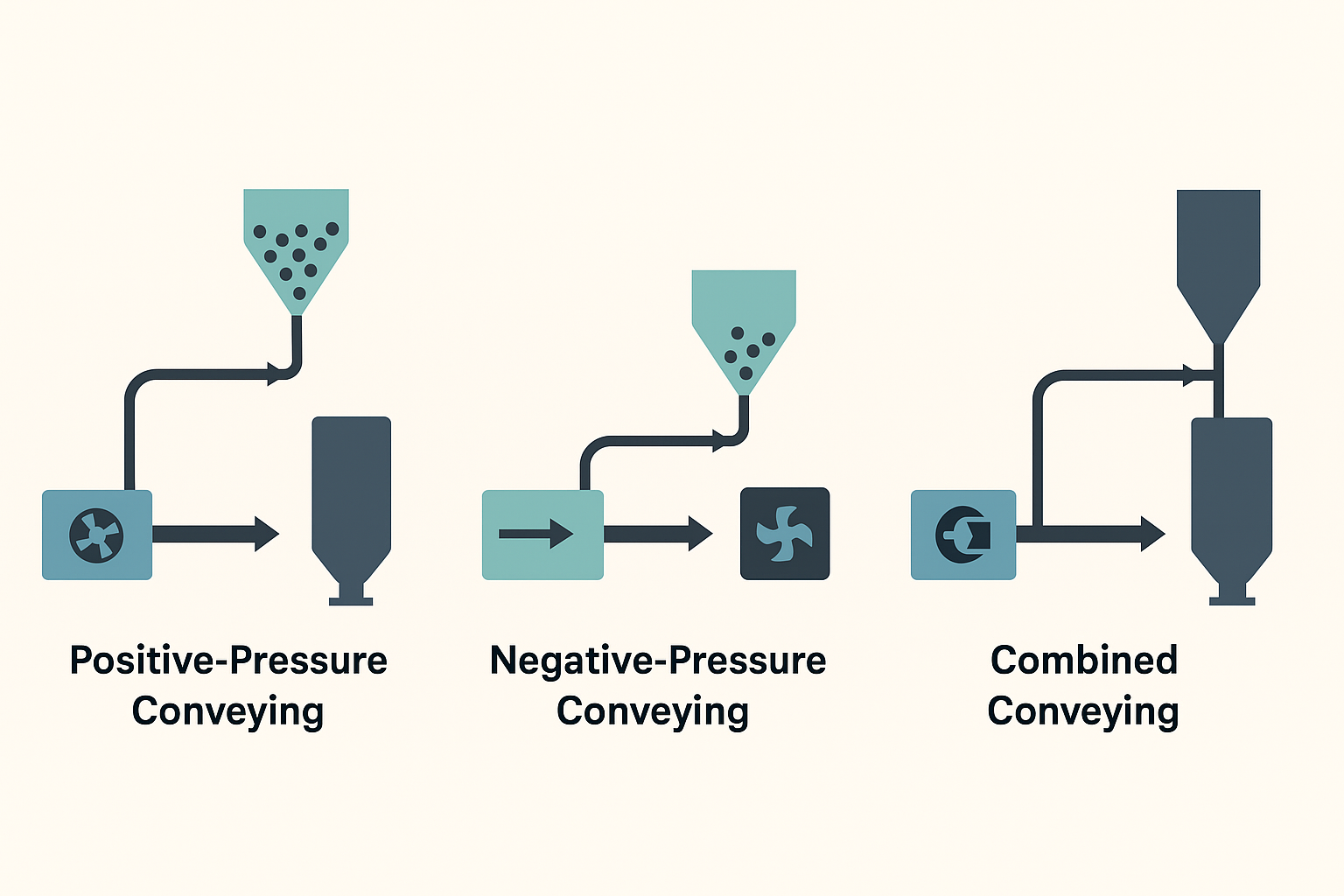

Pneumatic conveying refers to the transportation of powdered or granular materials through pipelines using air flow. It can be classified by driving method and conveying mode:

Positive-pressure conveying: Air pushes the material forward (similar to a blower pushing objects).

Negative-pressure conveying: Air sucks the material forward (similar to a vacuum cleaner).

Combined conveying: Integrates pushing and suction for more complex conditions.

By solid loading ratio, it is further divided into:

Dilute-phase conveying: Low solids concentration, high velocity (dust-like suspension).

Dense-phase conveying: High solids concentration, low velocity (sand-like slug flow).

2. Pressure Requirements in Pneumatic Conveying

The stability and efficiency of pneumatic conveying depend heavily on system pressure. Proper pressure must:

Provide sufficient driving force to overcome pipeline friction and material gravity.

Prevent blockages caused by insufficient pressure.

Improve efficiency by reducing energy consumption at appropriate pressure levels.

Ensure safety by keeping pressure within equipment and pipeline limits.

Typical conveying pressures range from 0.1 to 0.6 MPa. Higher values are required for long distances, high-density materials, or higher throughput.

Table 1 — Typical Conveying Pressures for Common Materials

| Material | Bulk Density (kg/m³) | Typical Phase | Conveying Distance (m) | Typical Pressure Range (MPa) | Notes |

|---|---|---|---|---|---|

| Flour | 400 – 600 | Dilute phase | 50 – 200 | 0.10 – 0.25 | Hygienic requirement; avoid contamination |

| Sugar | 800 – 900 | Dilute phase | 50 – 150 | 0.15 – 0.30 | Requires smooth pipeline to prevent sticking |

| Milk Powder | 400 – 600 | Dilute phase | 50 – 150 | 0.12 – 0.25 | Sensitive to heat; gentle conveying preferred |

| Cement | 1200 – 1500 | Dense phase | 100 – 300 | 0.25 – 0.45 | Long-distance conveying; high wear |

| Lime Powder | 900 – 1100 | Dense phase | 100 – 200 | 0.20 – 0.40 | Tends to absorb moisture |

| PVC Powder | 500 – 700 | Dense phase | 100 – 250 | 0.30 – 0.50 | Electrostatic risk; requires grounding |

| Coal Powder | 700 – 900 | Dense phase | 150 – 300 | 0.25 – 0.45 | Common in power plants for boiler feed |

| Fly Ash | 800 – 1000 | Dense phase | 100 – 300 | 0.20 – 0.40 | Often recovered from ESP/boiler system |

3. Pressure Loss Mechanisms

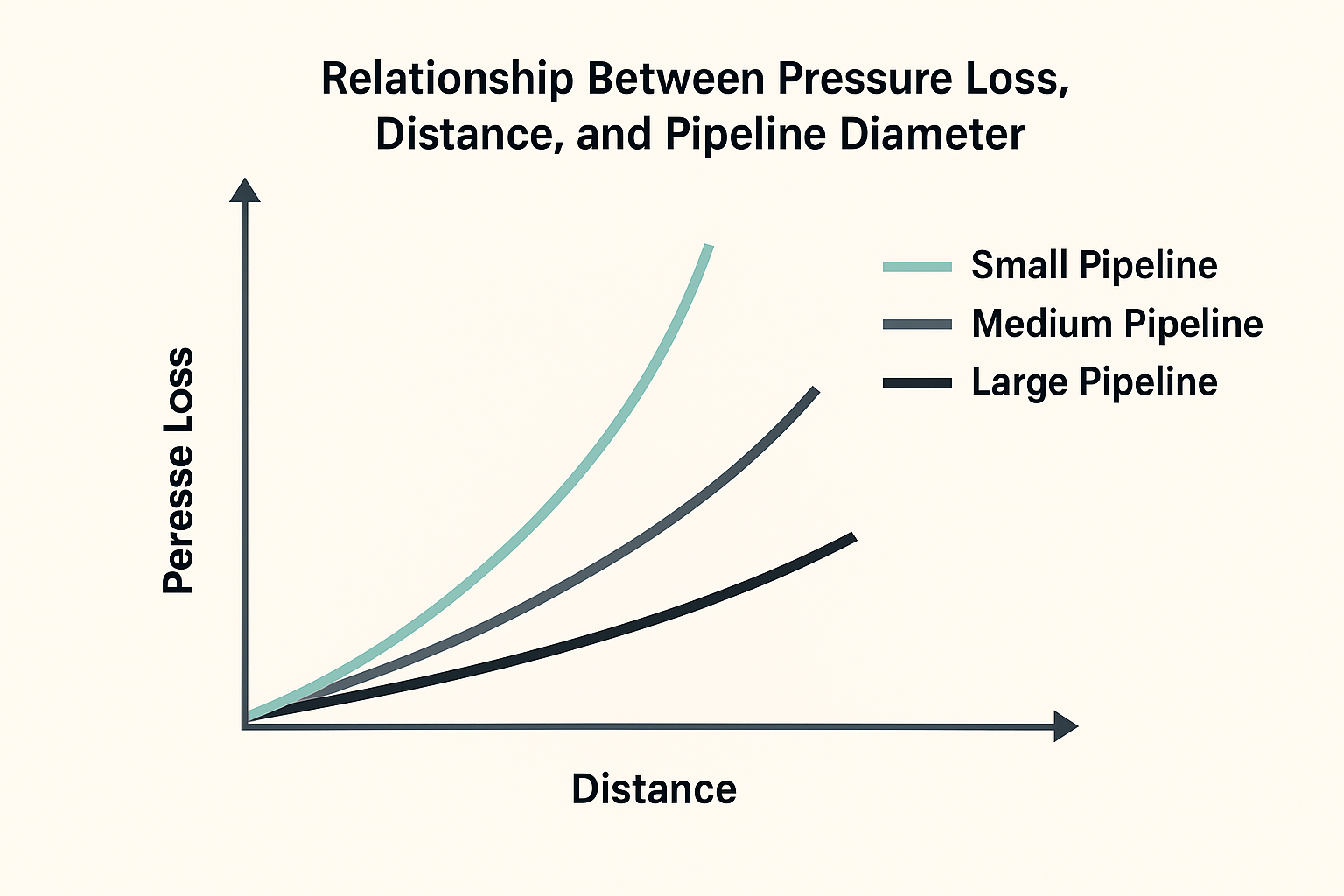

As materials move through the pipeline, pressure gradually decreases due to:

Friction along pipeline length.

Smaller diameters increasing resistance.

Heavier or rougher particles generating more drag.

Bends, elbows, and junctions adding localized resistance.

Low gas-to-solid ratio (G/S) increasing losses.

Optimization measures include:

Designing pipelines with fewer bends and larger diameters.

Adjusting G/S ratio to avoid particle deposition.

Selecting proper conveying velocity.

Using wear-resistant, smooth inner-wall materials.

4. Causes of Pressure Fluctuation

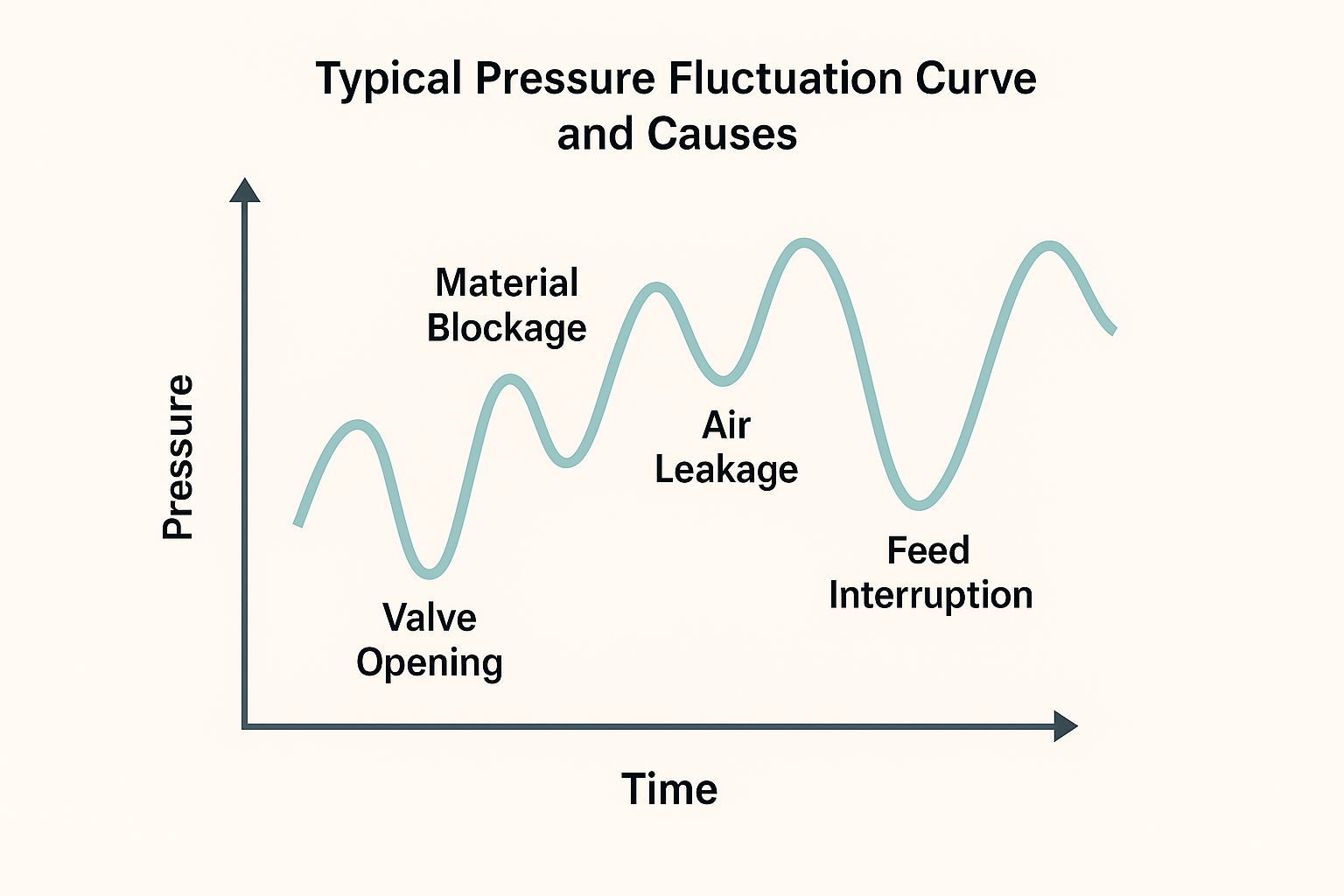

System pressure is rarely constant during operation. Common fluctuation factors include:

Material variations: Higher moisture content increases resistance.

Equipment issues: Unstable compressor or vessel pump performance.

Pipeline wear: Roughened walls raise resistance.

Operational errors: Sudden valve switching causes abrupt changes.

Countermeasures: Continuous monitoring, preventive maintenance, and strict operating procedures.

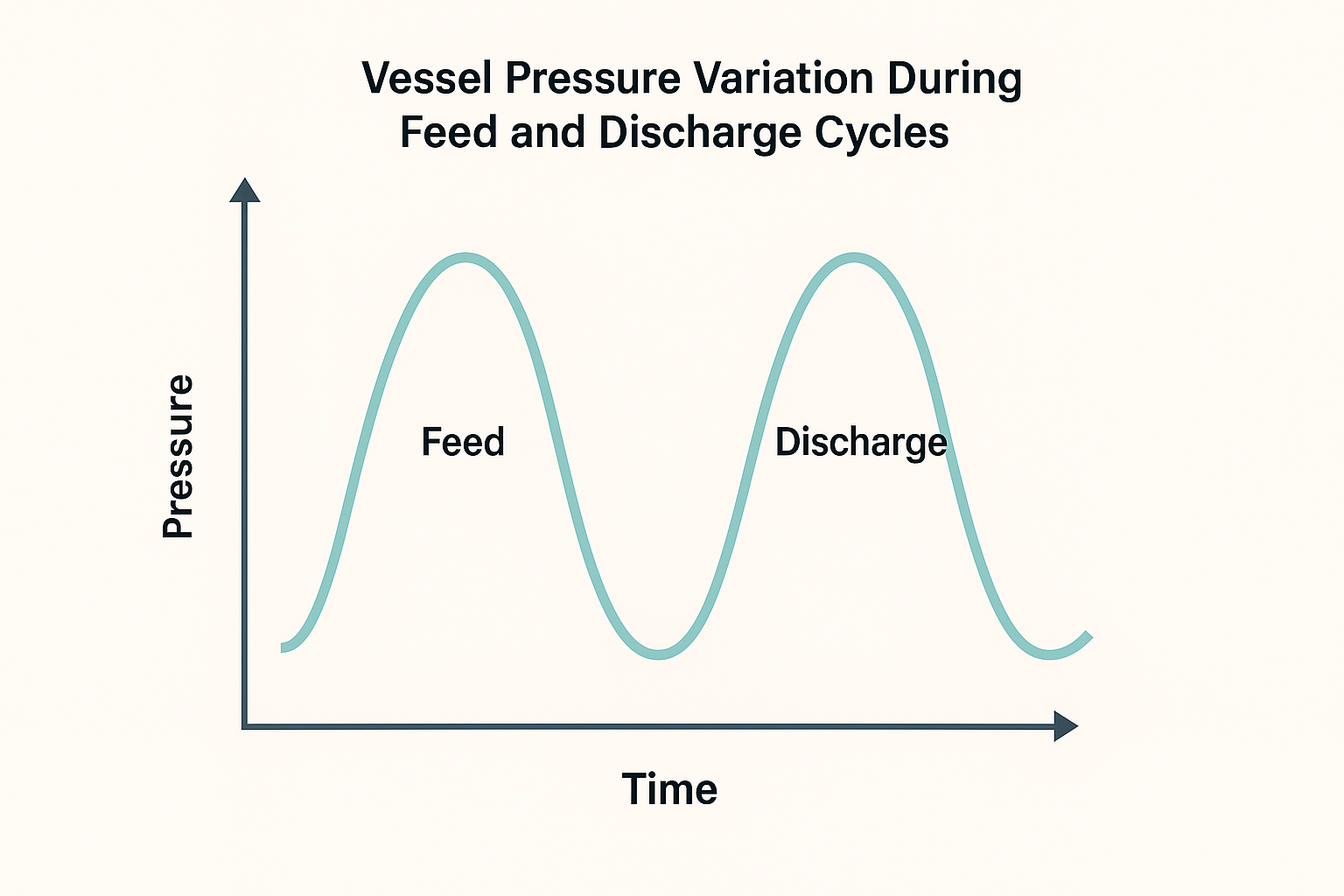

5. Pressure Behavior in Conveying Vessels (Tank/Pot)

The conveying vessel (tank or pot) is the heart of many dense-phase systems. Its internal pressure stability directly affects discharge performance. Influencing factors include:

Feeding rate: Excessive feeding increases pressure; insufficient feeding lowers it.

Discharge rate: Too slow causes buildup; too fast leads to sudden pressure drop.

Gas supply stability: Pressure and flow fluctuations are reflected inside the vessel.

Sealing quality: Worn or leaking seals reduce internal pressure.

To stabilize vessel pressure: control feed/discharge balance, ensure stable air supply, and maintain seals regularly.

6. Industrial Applications and Advantages

Pneumatic conveying systems are widely applied:

Food industry: Hygienic transport of flour, sugar, milk powder.

Building materials: Long-distance transport of cement, lime powder.

Chemical industry: Powdered resin and PVC conveying with reduced contamination.

Energy sector: Coal powder and fly ash transport in power plants.

Advantages:

Enclosed conveying prevents dust pollution.

Flexible pipeline layout adapts to complex plant environments.

High automation reduces manual handling.

Clean and safe operation, especially in food and pharmaceutical industries.

Table 2 — Industry Applications vs. Advantages of Pneumatic Conveying

| Industry | Typical Materials Conveyed | Key Advantages |

|---|---|---|

| Food & Beverage | Flour, sugar, milk powder, coffee beans | • Hygienic, enclosed transport • Prevents contamination • Suitable for clean-room environments |

| Pharmaceutical | Active pharmaceutical ingredients (APIs), excipients, powders | • Dust-free handling • High automation for dosing/packaging • Meets GMP requirements |

| Building Materials | Cement, lime powder, gypsum, fly ash | • Long-distance conveying (hundreds of meters) • High throughput capacity • Reduced manual labor and dust emissions |

| Chemical Industry | PVC powder, resins, catalysts, additives | • Reduced environmental pollution • Flexible layout to adapt to complex plants • Safe handling of fine/reactive powders |

| Energy & Power | Coal powder, biomass, fly ash | • Reliable large-scale transport • Minimizes dust explosion risks • Integration with automated boiler feed systems |

| Metallurgy | Alumina, mineral concentrates, metal powders | • Enclosed system reduces product loss • Protects workers from harmful dust • High efficiency in bulk transfer |

7. Conclusion

Pneumatic conveying acts as an “air express system” in factories, with pressure control as the driving engine for efficiency, safety, and stability.

During design, consider pressure requirements, loss, and fluctuation.

During operation, emphasize monitoring, maintenance, and optimization.

With advancements in materials, system design, and intelligent control, pneumatic conveying will continue to evolve toward higher efficiency, energy savings, and environmental friendliness.