In industrial operations, it’s common for engineers and inspectors to ask:

“Must every pressure gauge have a red line indicating the maximum working pressure?”

And if a gauge lacks this red mark, does it represent a safety hazard?

Let’s explore this question from three critical perspectives: the purpose of the red mark, relevant regulatory requirements, and practical safety implications.

1. What Is the Purpose of the Red Mark on a Pressure Gauge?

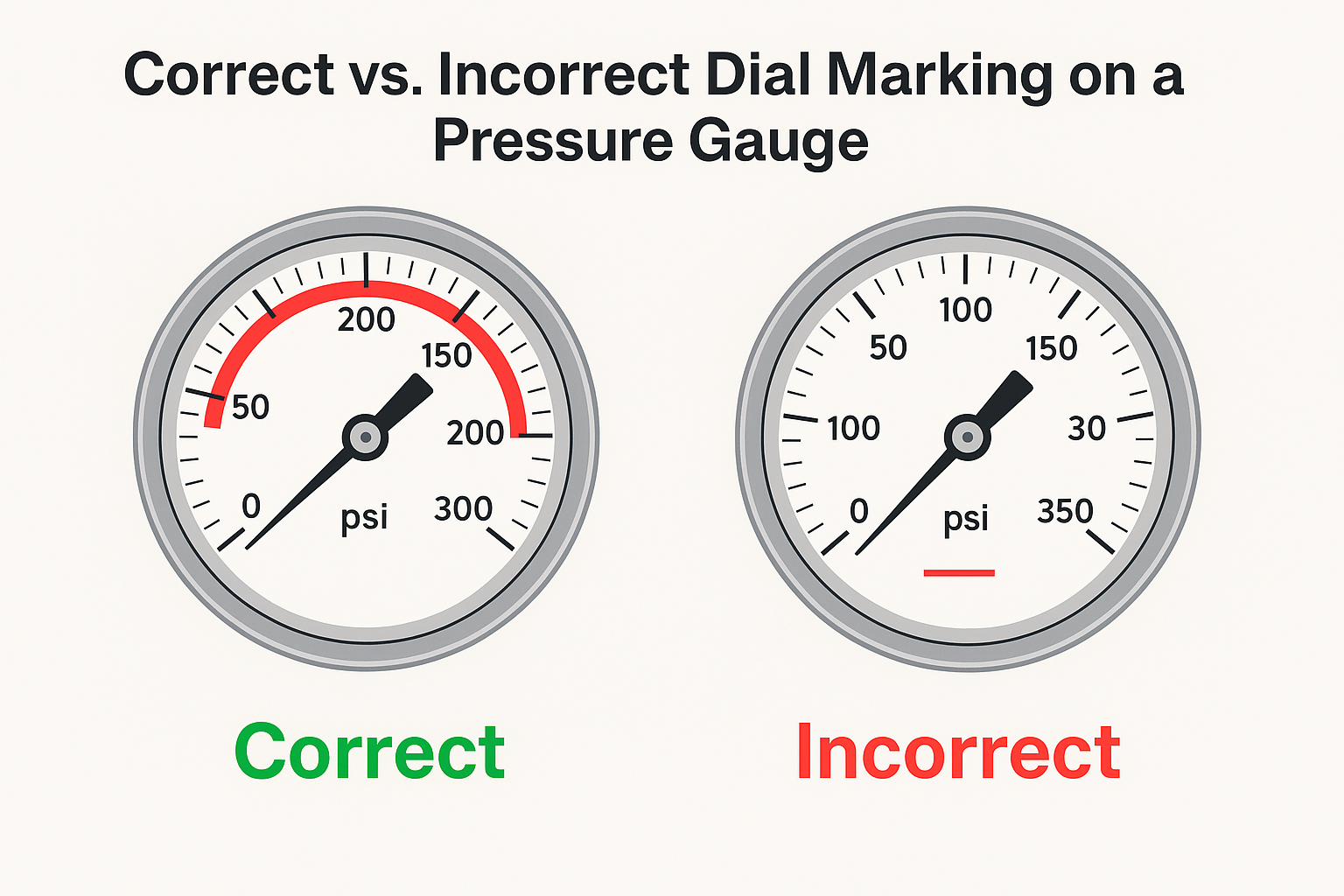

The red line—usually drawn across the dial of a pressure gauge—serves as a visual indicator of the device’s safe working pressure or maximum allowable working pressure (MAWP).

✅ Primary Functions:

Provides an intuitive safety reference for operators;

Allows for quick detection of abnormal pressure conditions;

Helps prevent overpressure-related accidents;

Enhances overall situational awareness during operation.

Although this practice is widely encouraged, the key question remains: Is it mandatory?

2. What Do the Standards and Regulations Say?

Let’s examine the technical and legal basis by reviewing several important national and industry standards.

📘 TSG 21-2016 – Safety Technical Regulation for Stationary Pressure Vessels

Clause 9.2.1.2:

“Pressure gauges must be calibrated before installation. A red line indicating the working pressure shall be drawn on the dial, and the next calibration date shall be marked. Calibration seals shall be applied.”

✅ Mandatory red line requirement for pressure vessel applications.

📘 TSG 11 – Boiler Safety Technical Regulations

Clause 5.2.3:

“Pressure gauges shall be calibrated periodically. A red line indicating the working pressure must be drawn on the dial, and the next calibration date shall be indicated. The gauge must be sealed after calibration.”

✅ Similar mandatory requirement for boiler systems.

📘 AQ 3053 – Safety Technical Code for Vertical Cylindrical Steel Welded Storage Tanks

Clause 12.4.2:

“Pressure gauges shall be calibrated before installation. A red line indicating the working pressure must be drawn on the dial, and the next calibration date shall be marked. Gauges without valid calibration and seal shall not be used.”

✅ Mandatory red line for welded tank systems.

📘 GB/T 1226 – General Pressure Gauges

This is a recommended (non-mandatory) national standard for general-purpose pressure gauges.

🔸 No clause mandates red mark requirements.

3. Summary Table: Red Line Requirement Across Equipment Types

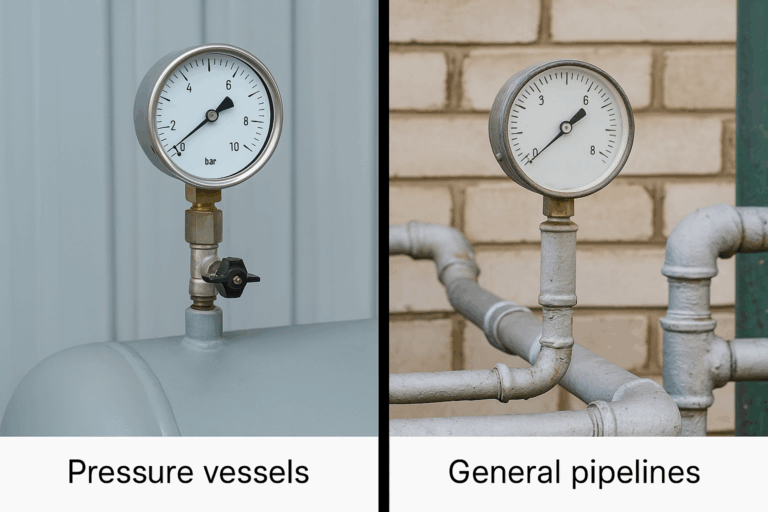

| Equipment Type | Red Mark Required? | Regulation Cited | Notes |

|---|---|---|---|

| Pressure Vessel | ✅ Yes | TSG 21-2016 | Must be calibrated, sealed, and marked |

| Boiler System | ✅ Yes | TSG 11 | Same as above |

| Storage Tank | ✅ Yes | AQ 3053 | Same as above |

| General Pipeline Gauge | ❌ No | GB/T 1226 (optional) | Not mandatory, but recommended for safety |

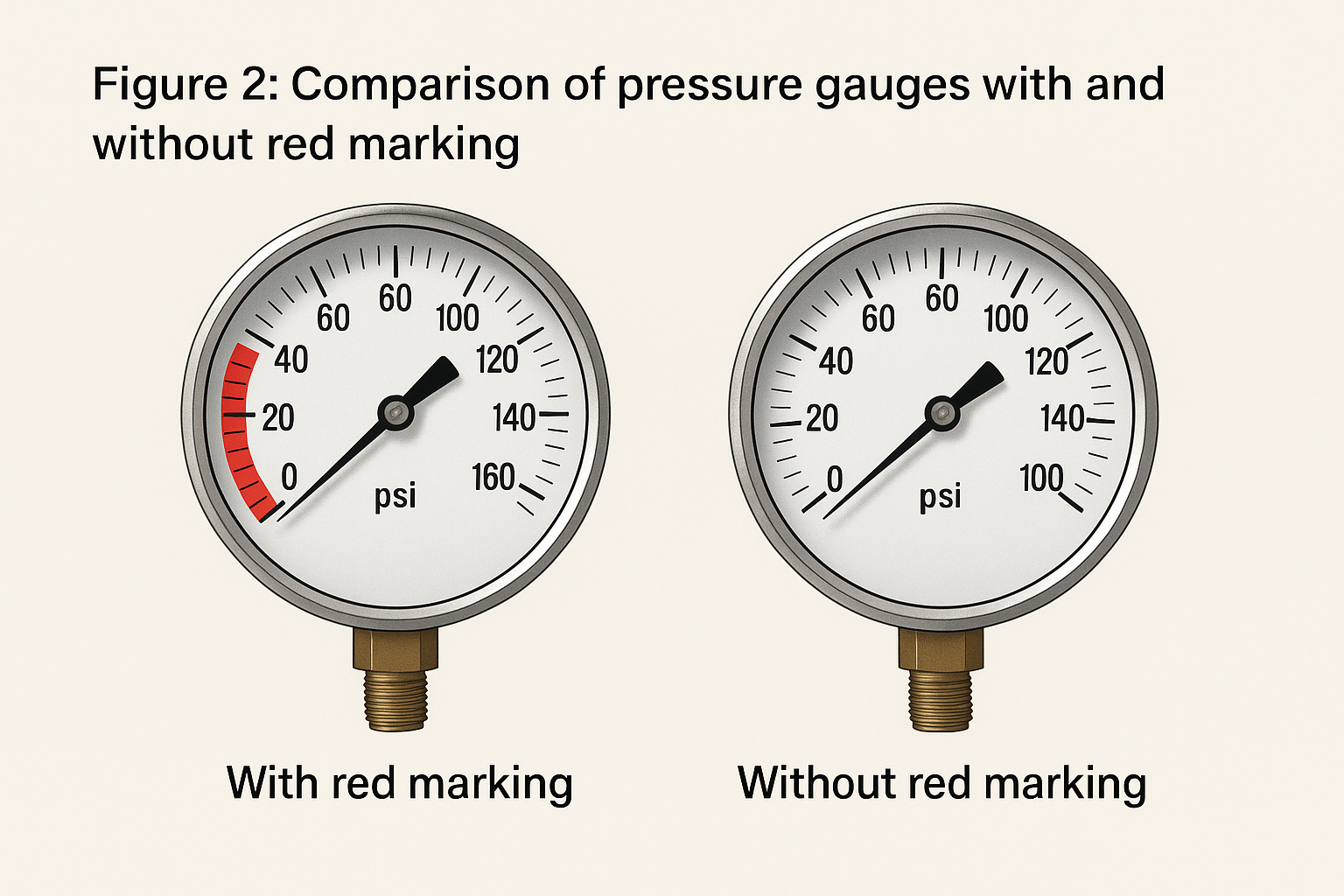

4. Is the Absence of a Red Line a Safety Hazard?

Not necessarily.

For applications not covered by the above mandatory regulations—such as general pipeline monitoring—the lack of a red line does not violate standards and should not automatically be classified as a safety risk.

However, marking the working pressure on the dial is still considered a best practice, especially in high-risk or high-traffic areas, and is highly recommended for operational convenience and risk mitigation.

Conclusion

While red line indicators on pressure gauges play an important role in operational safety and compliance, they are only mandatory in certain regulated systems, such as pressure vessels, boilers, and storage tanks. For other applications, their presence is a safety enhancement—not a legal requirement.

Bottom Line:

Always consult applicable safety regulations for your specific equipment class. When in doubt, adding a red mark is a low-cost, high-impact safety improvement.