Vortex flowmeters are widely used in various industries due to their reliability and versatility. However, during operation, interference signals can affect measurement accuracy. This article analyzes the common sources of interference and provides detailed solutions to mitigate or eliminate their impact.

Common Sources of Interference

Fluid Fluctuations

The presence of bubbles, suspended particles, or other impurities in the fluid can disrupt the detection of vortices, leading to inaccurate measurements.Instability in Fluid Velocity

Sudden changes in fluid velocity, caused by upstream flow disturbances or operational conditions, can alter the signal waveform and compromise measurement precision.Mechanical Vibrations

Vibrations from nearby equipment, such as pumps, valves, or poorly supported pipelines, can interfere with the signal collection process in the flowmeter.Electromagnetic Interference (EMI)

Power lines, signal cables, and other electrical equipment can generate electromagnetic noise, adversely impacting the flowmeter’s signal accuracy.

Solutions to Mitigate Interference

Selecting the Appropriate Vortex Flowmeter

Choose a flowmeter that matches the specific fluid characteristics and application environment. For instance:- Use vortex flowmeters designed for fluids containing particles or bubbles.

- Opt for flowmeters with enhanced signal processing capabilities to filter out noise.

Optimizing Pipeline Layout

To ensure a stable flow profile:- Install sufficient straight pipe sections upstream and downstream of the flowmeter. As a rule of thumb, use at least 10 times the pipe diameter (10D) upstream and 5D downstream.

- Avoid sharp bends, valves, or obstructions close to the flowmeter to minimize flow disturbances.

Reducing System Vibrations

- Secure pipelines and associated equipment to reduce excessive movement.

- Install vibration-dampening devices, such as rubber joints or spring supports, to isolate the flowmeter from external vibrations.

- For high-vibration environments, consider using flowmeters with built-in vibration compensation features.

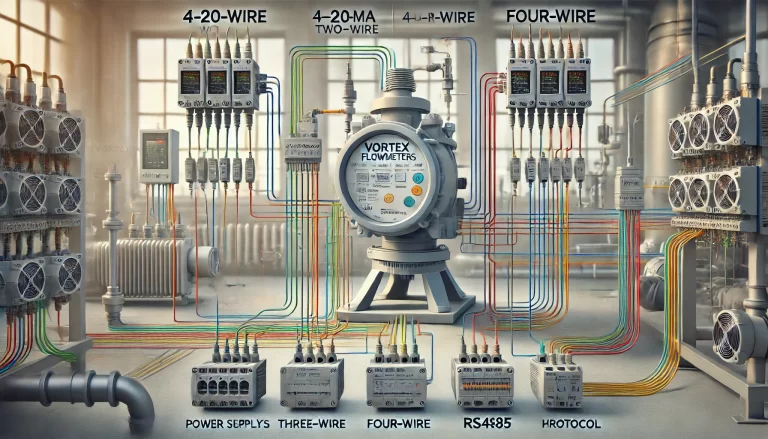

Improving Cable Management

Proper electrical wiring can significantly reduce electromagnetic interference:- Use shielded cables for signal transmission, ensuring the shield is correctly grounded.

- Separate power lines, signal cables, and grounding wires to minimize crosstalk.

- Avoid running signal cables in parallel with high-voltage lines.

Enhancing Grounding Systems

- Ensure the flowmeter and associated devices have reliable grounding to dissipate electromagnetic noise.

- Regularly inspect grounding connections to prevent corrosion or looseness that may reduce effectiveness.

Regular Maintenance and Inspection

- Periodically clean and inspect the flowmeter to remove buildup or debris that may obstruct the flow.

- Monitor the condition of the pipeline and associated equipment to detect potential sources of interference early.

- Replace aging components, such as sensors or cables, to maintain consistent performance.

Practical Example of Interference Mitigation

Consider a manufacturing plant experiencing fluctuating readings from a vortex flowmeter due to upstream flow instability. By installing a straight pipe section of 15D and a flow straightener, the flow profile became stable, reducing measurement errors by 25%. Additionally, replacing the standard signal cables with shielded ones reduced EMI-related disturbances, resulting in further accuracy improvements.

Conclusion

By understanding the sources of interference and implementing targeted solutions, it is possible to significantly enhance the accuracy and reliability of vortex flowmeters. These measures not only improve operational efficiency but also reduce maintenance costs and downtime, ensuring smooth industrial processes.