Orifice plate flow meters are widely used in industrial applications to measure fluid flow rates. Their accuracy, however, relies heavily on proper installation, particularly regarding the lengths of straight pipe required upstream and downstream. These straight sections help ensure a stable, predictable flow profile that yields accurate measurements. Below is a detailed exploration of the installation requirements, including a reference table summarizing key recommendations.

1. Why Straight Pipe Sections Are Essential

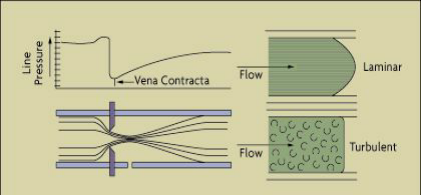

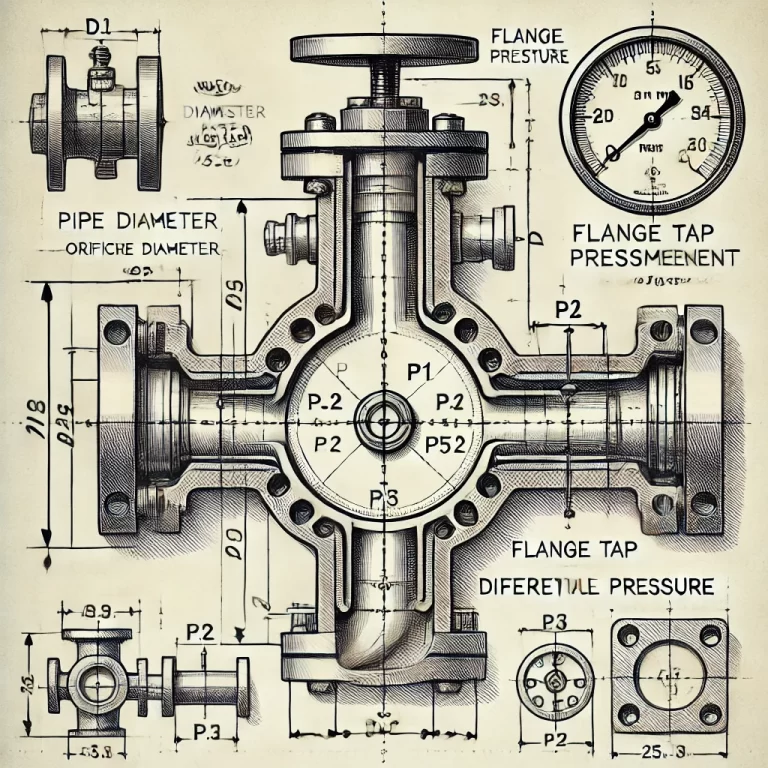

In fluid flow measurement, maintaining a stable, laminar flow profile before the fluid reaches the orifice plate is essential. When a fluid flows through pipes, any changes in the pipe geometry, such as bends, valves, or diameter reductions, can disturb the flow profile, creating turbulence. Turbulence or uneven velocity distribution can significantly affect the accuracy of the differential pressure measurement made by the orifice plate, leading to errors in flow calculations.

The straight pipe sections before and after the orifice plate help reduce these disturbances, allowing the fluid to stabilize. This stabilization results in a more predictable and symmetrical flow profile across the orifice, essential for accurate flow measurement.

2. Upstream Straight Pipe Requirement

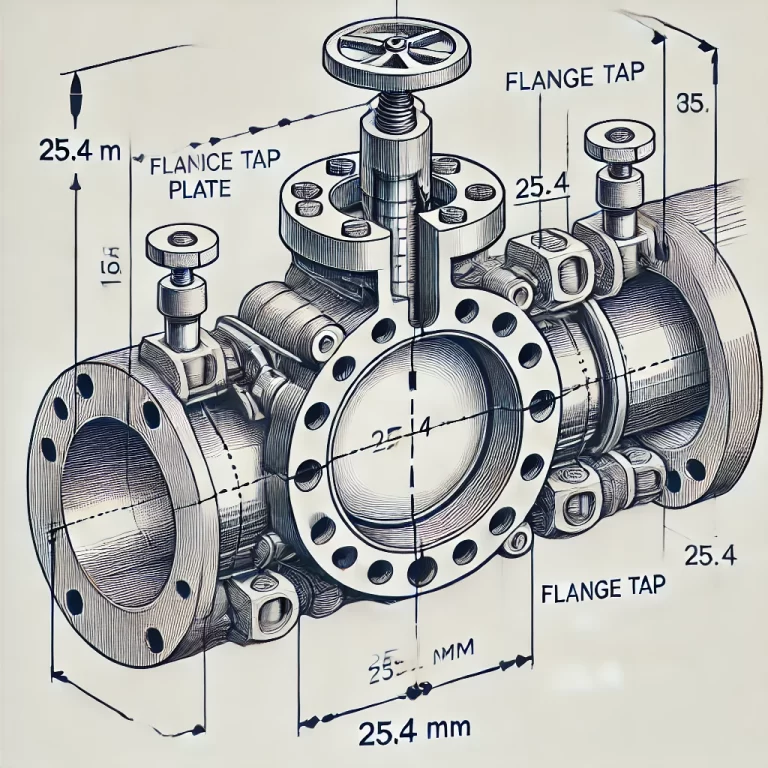

The upstream (inlet) straight pipe section is crucial for eliminating flow disturbances caused by upstream piping components such as bends, valves, or reducers. Depending on the level of upstream disturbance, the recommended length for this section may vary:

- Basic Requirement: Generally, a minimum of 20 times the diameter of the pipe (20D) is recommended as the upstream straight pipe section.

- For Greater Disturbances: If there are significant upstream disturbances (such as multiple bends in different planes, flow conditioning devices, or control valves close to the orifice), this length can increase to as much as 50D.

Following the recommended upstream straight pipe length allows the fluid to settle into a more uniform flow pattern before reaching the orifice, reducing the impact of velocity profile distortion on measurement accuracy.

3. Downstream Straight Pipe Requirement

The downstream (outlet) straight pipe section is typically shorter than the upstream section but is still important for measurement stability. Its primary function is to allow the fluid flow to recover after passing through the orifice:

- Basic Requirement: A minimum of 5 times the diameter of the pipe (5D) is typically recommended for the downstream straight pipe section.

- Higher Accuracy Requirement: In applications requiring high measurement precision or where downstream disturbances are present, this length may increase to 10D.

This section allows the fluid to stabilize after passing through the constriction, helping ensure that the orifice plate’s pressure differential remains consistent.

4. Installation Reference Table

For a quick reference, the table below summarizes recommended straight pipe lengths based on common upstream disturbances and general guidelines for orifice plate flow meters:

| Upstream Disturbance Type | Recommended Upstream Straight Pipe Length | Recommended Downstream Straight Pipe Length |

|---|---|---|

| No Disturbance | 20D | 5D |

| Single 90° Elbow | 25D | 5D |

| Two 90° Elbows (Same Plane) | 25D | 5D |

| Two 90° Elbows (Different Planes) | 30D | 5D |

| Reducer or Expander | 25D | 5D |

| Valve (Control or Throttle) | 30D to 50D (Depending on disturbance level) | 5D to 10D |

| Pumps or Compressors (High Turbulence) | 50D | 10D |

| Flow Conditioner Installed | 10D to 15D | 5D |

Notes:

- D represents the inner diameter of the pipe.

- Upstream Length Variability: The upstream length varies significantly based on the type of disturbance.

- Downstream Length: Typically shorter but may require an extension to 10D in high-accuracy applications.

5. Additional Considerations: Flow Disturbances and Flow Conditioners

Certain upstream piping arrangements can significantly disturb fluid flow, requiring additional measures:

- Elbows and Bends: Elbows immediately upstream can create asymmetric flow profiles. If unavoidable, consider installing flow conditioners or increasing the straight pipe length to help stabilize the flow.

- Valves: Control valves or throttling devices cause substantial turbulence. It is best to position these devices far upstream, but if close proximity is unavoidable, extending the upstream pipe length or using flow straighteners can mitigate their impact.

- Flow Conditioners: In highly sensitive applications, flow conditioners or straightening vanes can be installed to help create a more uniform flow profile in shorter straight pipe sections.

6. Importance of Following Industry Standards

Various industry standards, such as ISO 5167 and ASME MFC-3M, provide specific guidelines on orifice plate installations, including recommended straight pipe lengths based on different configurations. Following these standards is crucial, as they offer established, tested methodologies to achieve optimal accuracy.

7. Conclusion

Proper installation of orifice plate flow meters, especially ensuring sufficient straight pipe lengths upstream and downstream, is essential for obtaining accurate and reliable measurements. By understanding and applying these guidelines—20D to 50D upstream and 5D to 10D downstream—users can minimize the impact of flow disturbances and ensure the integrity of their flow measurement data.