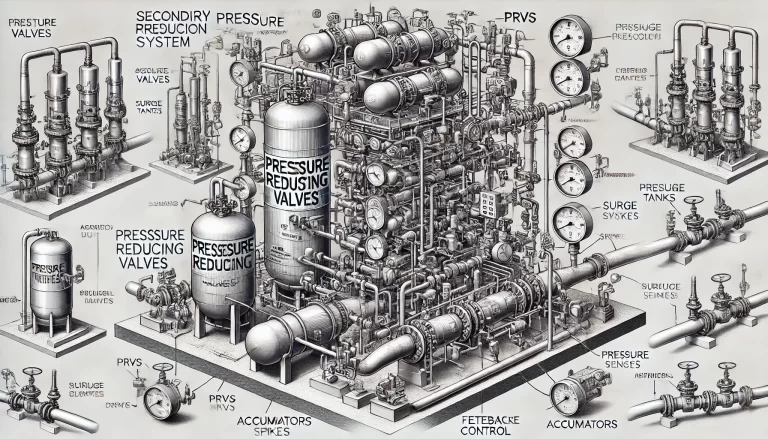

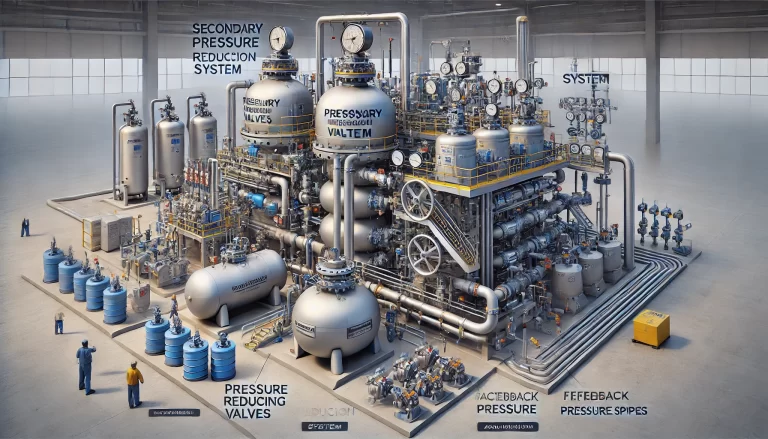

Pressure control is crucial for the safety, efficiency, and longevity of various industrial and mechanical systems. Secondary pressure reduction, commonly referred to as secondary pressure regulation, involves further reducing and controlling pressure within a system after an initial reduction phase. Maintaining stable pressure at this stage is vital to prevent fluctuations that could lead to system failures, operational inefficiencies, or even accidents. Here’s a detailed guide on how to achieve effective and stable pressure control in a secondary pressure reduction system.

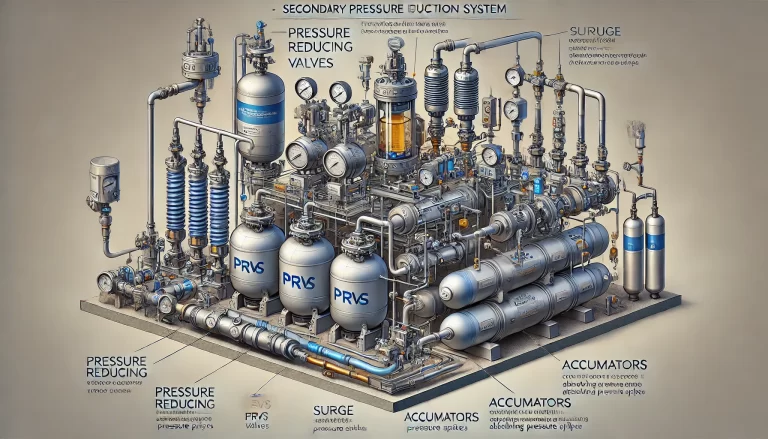

1. Utilizing Pressure Reducing Valves (PRVs)

Pressure reducing valves (PRVs) are one of the most reliable tools for controlling pressure in a system. These valves automatically adjust the flow of fluid or gas to ensure that the downstream pressure remains constant, despite changes in the upstream pressure or flow rate. Here’s how PRVs work to stabilize pressure:

- Self-adjusting mechanism: PRVs are designed with a diaphragm and spring mechanism that responds to pressure changes. When the downstream pressure exceeds the setpoint, the valve closes slightly to reduce the flow, maintaining a stable pressure output.

- Adjustable setpoints: Many PRVs allow operators to manually set the desired pressure level, providing flexibility to adapt to different system requirements.

- Regular maintenance: To ensure consistent performance, PRVs should be regularly inspected, cleaned, and calibrated. Over time, debris or wear can affect their precision, leading to pressure instability.

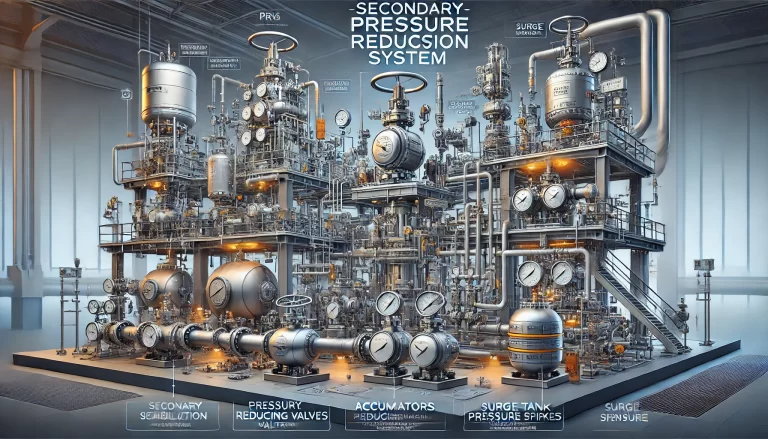

2. Adding Accumulators or Surge Tanks

Accumulators (also known as surge tanks) are used to smooth out pressure fluctuations by storing excess fluid or gas during high-pressure periods and releasing it when the pressure drops. Here’s how they help stabilize pressure:

- Absorption of pressure spikes: When a sudden increase in pressure occurs, the accumulator absorbs the excess fluid, preventing it from reaching downstream equipment and causing damage.

- Release during low pressure: During periods of low pressure, the stored fluid is released from the accumulator to maintain a consistent pressure in the system.

- Sizing considerations: Proper sizing of the accumulator is crucial. Too small of an accumulator won’t effectively buffer pressure, while one that is too large may result in slow pressure response times. An expert should calculate the optimal size based on system needs.

3. Implementing Pressure Sensors with Feedback Control Systems

Automated pressure control systems, equipped with pressure sensors and feedback loops, can significantly enhance pressure stability. The key to this approach lies in continuous monitoring and adjustment:

- Real-time monitoring: Pressure sensors continuously measure the pressure within the system and send data to a control unit.

- Feedback mechanism: When the sensor detects deviations from the desired pressure, the control system adjusts actuators, valves, or other components to bring the pressure back to the setpoint. This process is often instantaneous, reducing the risk of large fluctuations.

- Precision control: Feedback systems can be incredibly precise, maintaining pressure within a narrow range. Advanced models allow operators to program pressure profiles that automatically adjust over time for dynamic systems.

4. Using Multistage Pressure Reduction

In systems where a significant reduction in pressure is needed, a multistage approach is often more effective than a single reduction step. Here’s why multistage pressure reduction can improve stability:

- Gradual pressure drop: Instead of reducing pressure in one dramatic step, multistage systems reduce pressure in stages, preventing sudden drops that could destabilize the system.

- Lower stress on equipment: Equipment exposed to sudden pressure changes is more prone to wear and tear. A multistage system spreads the pressure reduction across several stages, reducing the risk of equipment damage.

- Increased control: Each stage of pressure reduction can be fine-tuned for optimal performance, allowing for tighter control over the final pressure.

5. Optimizing Pipe and Flow Resistance

The design and layout of the system’s piping play an important role in pressure stability. By controlling flow resistance, operators can minimize fluctuations in pressure as the fluid or gas moves through the system.

- Pipe diameter: Larger diameter pipes reduce resistance to flow, which can help maintain stable pressure. However, too large of a pipe may slow down response times, making pressure regulation more difficult. It’s important to choose the correct size for the application.

- Dampening devices: Installing devices such as orifice plates, dampeners, or flow restrictors can help reduce pressure spikes by increasing flow resistance in key areas of the system.

- Eliminate sharp bends: Avoiding sharp turns in the piping system reduces turbulence and pressure loss. Smoother bends create a more consistent flow and reduce sudden pressure variations.

6. Regular Maintenance and Calibration of Equipment

No matter how well-designed a system is, equipment degradation over time can lead to pressure instability. Regular maintenance is critical to ensure that all components in the pressure control system are functioning correctly.

- Inspect and clean valves: Valves are susceptible to buildup from debris or sediment, which can affect their ability to regulate pressure effectively. Regular cleaning ensures they operate smoothly.

- Calibrate sensors and controllers: Pressure sensors and automated controllers should be recalibrated periodically to maintain accuracy. Calibration ensures that pressure readings are correct and that the control system can make the necessary adjustments in a timely manner.

- Monitor wear on parts: Components like diaphragms, seals, and springs in pressure control devices wear out over time. Replacing worn parts ensures that the system continues to function optimally.

7. Adjusting Operating Conditions

Finally, operational procedures themselves can be optimized to reduce pressure fluctuations. Minimizing abrupt changes in load, flow rate, or temperature can prevent rapid pressure swings.

- Gradual changes: When adjusting the flow rate or pressure setpoints, operators should make changes gradually rather than suddenly. This gives the system time to adapt without causing large pressure shifts.

- Scheduling load variations: If possible, spread out periods of heavy usage or high demand over time to avoid sudden spikes in pressure.

- Monitoring and analysis: Regular monitoring of system performance, coupled with data analysis, can help identify patterns that lead to pressure instability. Addressing these issues can lead to smoother, more predictable operation.

Conclusion

Stabilizing pressure in a secondary pressure reduction system is essential for the safe and efficient operation of any pressurized system. By using tools like pressure reducing valves, accumulators, feedback control systems, and by implementing best practices such as multistage reduction and regular maintenance, operators can ensure stable pressure control. Optimizing piping design and adjusting operational procedures further enhance the system’s ability to maintain consistent pressure, reducing the risk of fluctuations that could lead to costly downtime or damage. Properly managing these factors creates a more reliable and resilient pressure management system that can operate effectively over time.