1. Why Instrument Grounding Matters

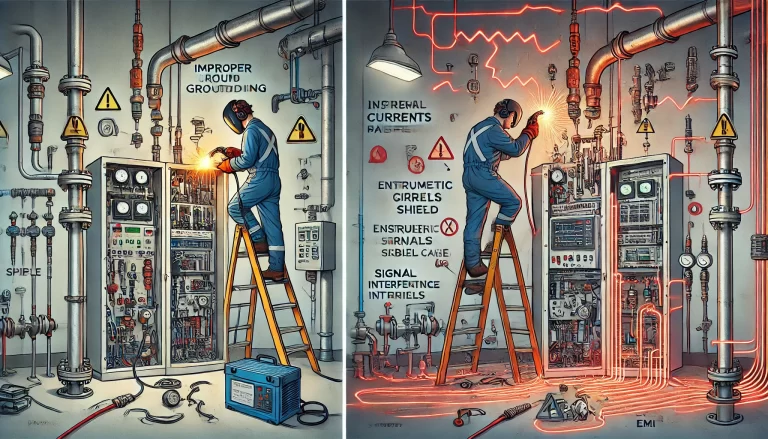

In chemical production environments, instrumentation systems serve as the “eyes and brain” for monitoring and controlling processes, while grounding systems act as the “lifeline” for operational safety and stability. Improper grounding can result in signal interference, data distortion, or even catastrophic incidents such as fires and explosions.

Grounding is essential for:

✅ Safety Protection

Prevent lightning damage and static buildup.

Eliminate electrical sparks in explosive environments (e.g., Ex areas).

Protect personnel from electric shocks.

✅ Functional Reliability

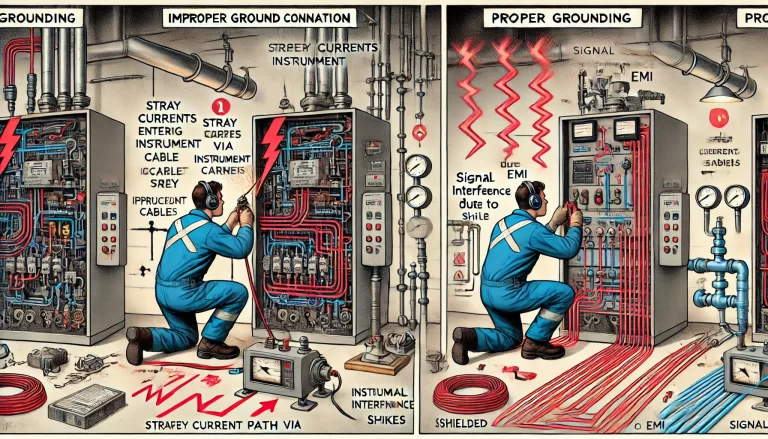

Reduce electromagnetic interference (EMI) and ensure accurate signal transmission (e.g., 4–20mA loops).

Eliminate common-mode voltage hazards to the control system.

2. Four Types of Grounding in Chemical Instrumentation

| Type | Purpose | Key Requirements | Application Scope |

|---|---|---|---|

| Signal Grounding | Reference voltage level, EMI reduction | ≤1Ω resistance, copper wire recommended | Analog/digital signal circuits |

| Protective Grounding | Prevents electrical hazards to personnel | ≤4Ω resistance, shared with electrical grounding mesh | Electrical cabinet shells, instrument panels |

| Static Grounding | Prevent static discharge in flammable areas | Independent ground rod, ≤100Ω | Pipes, tanks with flammable/explosive media |

| Lightning Grounding | Diverts lightning current safely to ground | Integrated with lightning protection, ≤10Ω | Outdoor tanks, towers, process units |

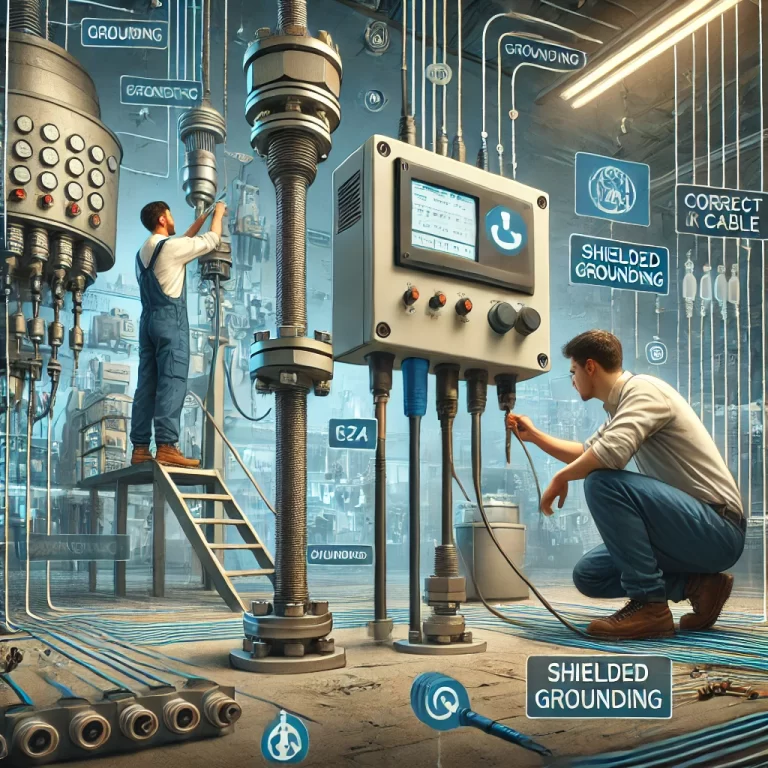

3. Design Standards and Best Practices

🧷 Grounding Material Selection

Prioritize copper conductors (corrosion-resistant, high conductivity)

Minimum cross-sectional area: ≥16mm² for multi-strand wires

Use galvanized flat steel ≥40mm×4mm for grounding main lines

🧪 Ground Resistance Requirements

Independent instrument grounding: ≤1Ω

Shared grounding: Must be co-designed with electrical systems

🔗 Equipotential Bonding

Interconnect all instrument cabinets, junction boxes, and metal conduits through a common ground bus

Eliminates voltage differentials between system components

🔒 Special Zones (Hazardous Areas)

Intrinsically safe systems must have a separate ground bus, isolated from non-intrinsically safe circuits

4. Installation and Inspection Guidelines

🔧 Installation Practices

Avoid routing ground wires parallel to power cables. If unavoidable, cross at 90°.

Ground rods should be buried ≥0.6m below surface (below frost line)

Apply grounding resistance-reducing agents as needed

🔍 Testing Requirements

Use professional testers such as Fluke 1625 for resistance verification

Avoid testing immediately after rain to prevent false readings

⚠️ Common Mistakes

❌ Direct welding of instrument cabinet to steel structure (introduces interference)

✅ Correct: Use insulating spacers and soft copper wires to connect to the ground bus

5. Maintenance and Grounding Integrity Management

Perform at least annual resistance testing, with additional checks before and after rainy seasons

Clear vegetation and debris near ground rods to reduce soil resistivity

Ground wires must be clearly marked (e.g., yellow-green) to prevent accidental disconnection

6. Real-World Incident: The Cost of Improper Grounding

At a chemical plant, a flow meter and a motor shared the same ground rod. When the motor leaked current, the signal system of the flow meter failed, causing a cascade shutdown of the production line.

Lesson Learned: Strictly separate grounding types to avoid interference and ensure system stability.