Liquid ammonia (NH₃) is a widely used industrial chemical, particularly in refrigeration systems, fertilizer production, and chemical processing. While invaluable in industry, it is toxic, corrosive, and hazardous under certain conditions. A leak can pose serious risks to people, property, and the environment, making it essential to have a clear, step-by-step response plan.

This guide outlines practical measures for safely managing a liquid ammonia leak — from immediate containment to personal protection and environmental precautions.

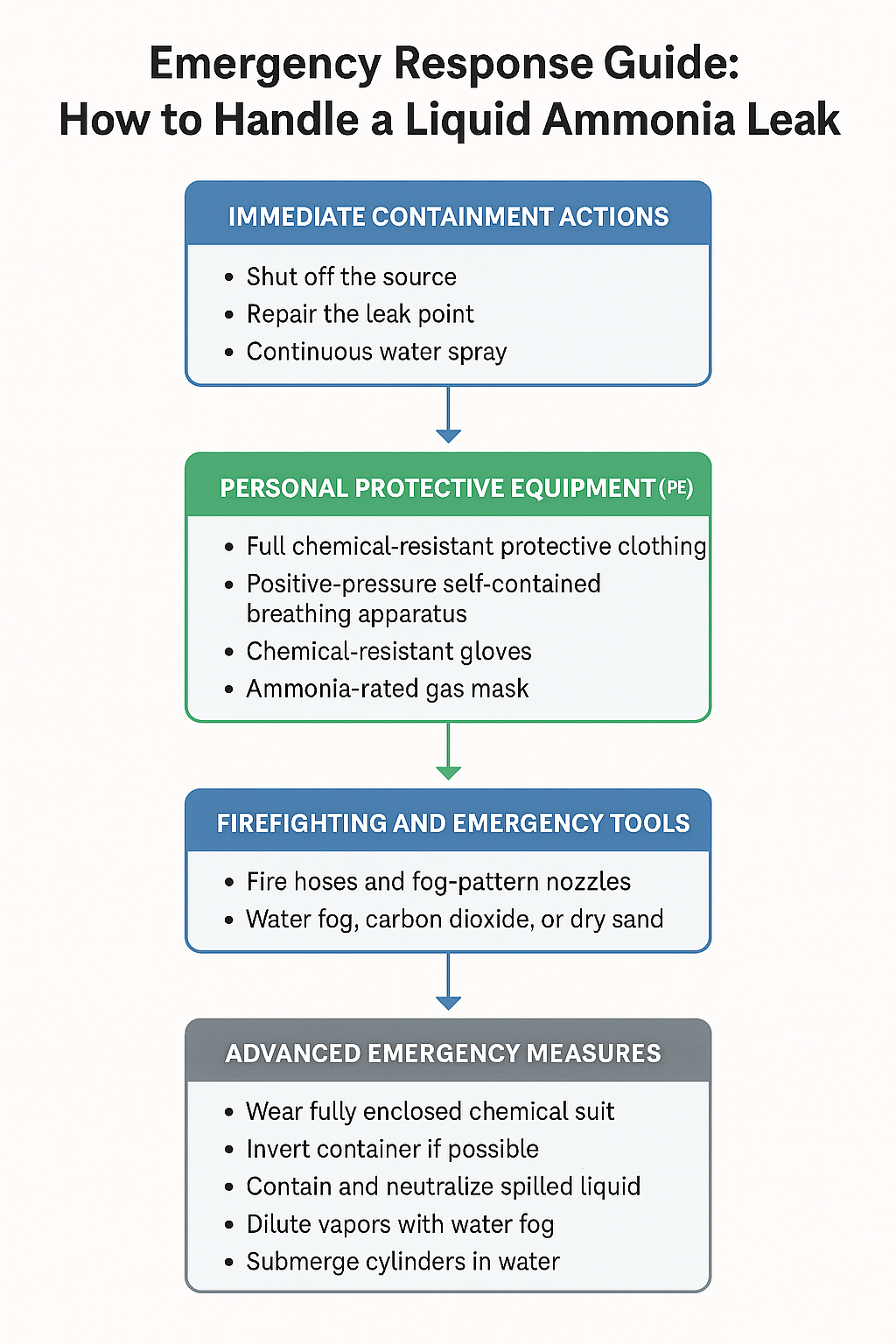

1. Immediate Containment Actions

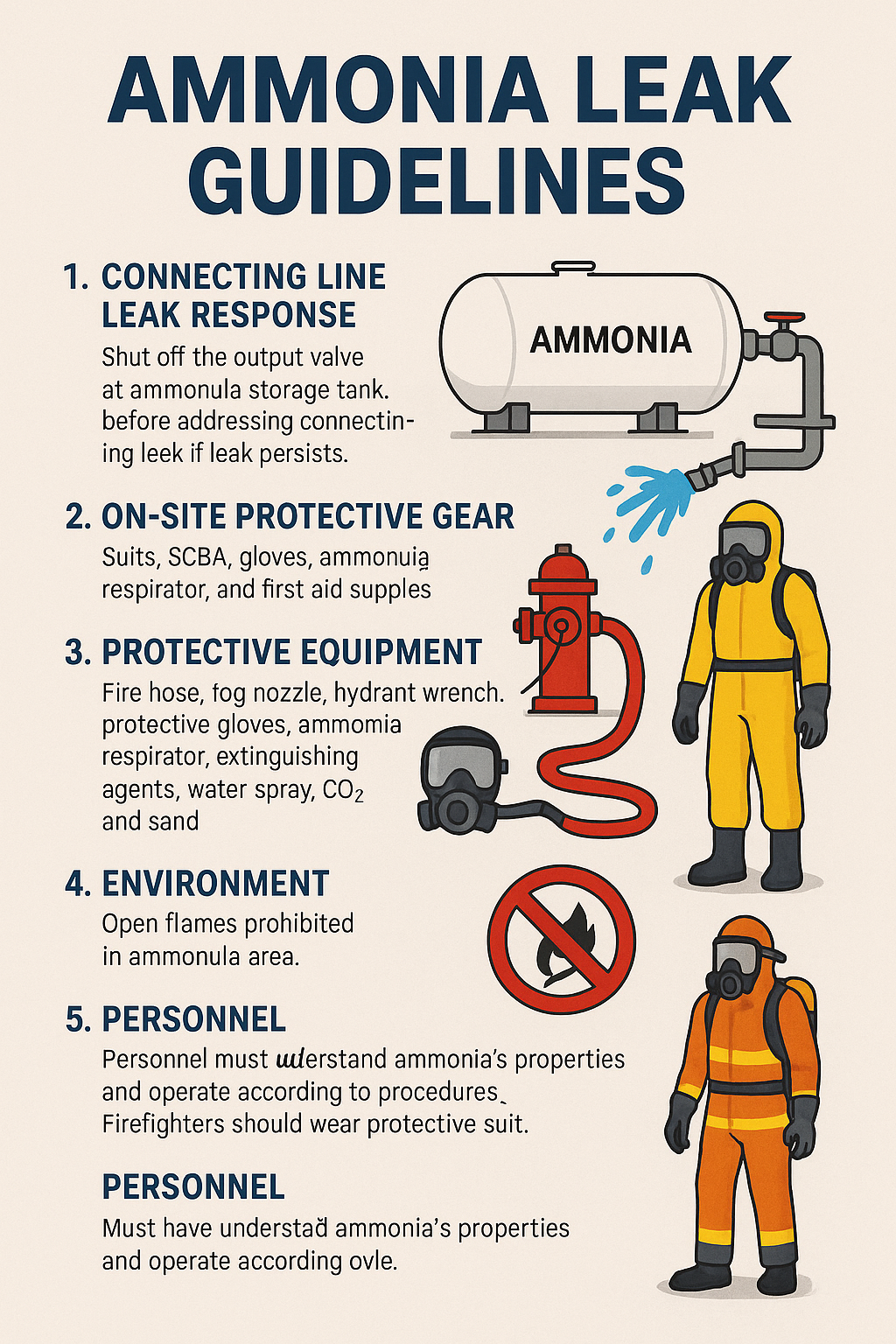

Pipeline or Connection Leaks

Shut Off the Source: Immediately close the outlet valve on the ammonia storage tank.

Repair the Leak Point: Once the source is isolated, address the leakage at the connection.

Continuous Water Spray: If leakage persists, apply a continuous spray of water to disperse and dilute the ammonia vapors.

During Filling or Unloading Operations

Close the connection valve on the filling line and isolate the system.

Eliminate all ignition sources in the area.

Establish a safety perimeter according to the gas dispersion zone. Evacuate non-essential personnel from the downwind and crosswind areas to an upwind safe zone.

2. Personal Protective Equipment (PPE)

When handling ammonia leaks, emergency responders must wear:

Full chemical-resistant protective clothing

Positive-pressure self-contained breathing apparatus (SCBA)

Chemical-resistant gloves

Ammonia-rated gas mask (for certain low-risk operations)

Emergency medical supplies on standby

3. Firefighting and Emergency Tools

Firefighting Equipment

Fire hoses, fog-pattern water nozzles, fire hydrant wrenches

Fire extinguishing agents: water fog, carbon dioxide, or dry sand

Special Precautions

In the event of fire near an ammonia leak, firefighting teams should operate from the upwind side, wearing full PPE and SCBA.

Avoid using direct water jets; use fog spray to absorb and disperse ammonia vapors.

4. Site Safety and Operational Requirements

No Open Flames: Absolutely no hot work or ignition sources in ammonia handling zones.

Trained Personnel Only: Operators must understand ammonia’s physical and chemical properties, follow strict operating procedures, and know emergency response protocols.

Coordination with Fire Services: Firefighters should be briefed on site layout, ammonia storage locations, and drainage systems before intervention.

5. Advanced Emergency Measures

For large-scale leaks or ruptures, follow these steps:

Wear a fully enclosed chemical protective suit with internal SCBA.

For liquefied gas leaks, take precautions against frostbite.

Avoid contact with or crossing over leaked material.

Cut off the leak source if possible. Prevent vapors from entering drains, ventilation ducts, or confined spaces.

If safe, invert the container so that only vapor escapes instead of liquid.

Build dikes or pits to contain liquid ammonia; neutralize with acetic acid or other weak acids.

Use water fog to dilute vapors while collecting contaminated water in containment areas for proper disposal.

If cylinders cannot be sealed, submerge them in water.

Storage tank areas should be equipped with water or weak acid spray systems for vapor suppression.

Isolate the area until all vapors have dispersed. Repair, inspect, and test any leaking containers before reuse.

Conclusion

A liquid ammonia leak can escalate quickly if not handled correctly. The keys to effective response are swift isolation of the source, proper use of PPE, thorough site safety control, and well-planned neutralization and containment measures. By training personnel in these procedures and equipping facilities with the right tools, industries can significantly reduce the risks associated with ammonia leaks.