1. Introduction

In industrial process control, disturbances such as sudden changes in input or load conditions can significantly affect system stability. While PID controllers are widely used for maintaining process setpoints, combining them with feedforward control can enhance responsiveness and reduce output fluctuations. This paper discusses how feedforward and PID control can work together, using furnace pressure control in coal-fired heating systems as an example.

2. Control Strategy Overview

2.1 PID Control

Proportional–Integral–Derivative (PID) control is effective in managing system errors based on historical and current deviations between process variables and setpoints. However, it reacts only after a disturbance has impacted the process.

2.2 Feedforward Control

Feedforward control, on the other hand, predicts the impact of measurable disturbances and compensates for them before they affect the process. When integrated with a PID controller, the system becomes more resilient and responsive.

3. Application Example: Furnace Pressure Control

In a coal-fired furnace, maintaining a slightly negative pressure at the furnace outlet is crucial for safe and efficient operation. A PID controller adjusts the induced draft fan speed to regulate the pressure:

If the pressure increases, fan speed is raised to enhance exhaust airflow, lowering pressure.

If the pressure decreases, fan speed is reduced, decreasing exhaust flow and raising the pressure.

However, the primary source of disturbance in this process is the varying airflow rate, which correlates with coal feed rate. To preemptively counteract this disturbance, a feedforward signal based on the air supply rate is introduced.

🔧 Figure Suggestion

Title: Furnace Pressure Control Using Combined Feedforward and PID Control

Content: Diagram showing:

Setpoint (desired pressure)

Disturbance (air supply rate)

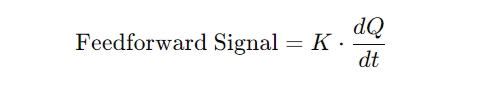

Feedforward path with a function F(x) = K·dQ/dt

PID path with summed input (setpoint – feedforward)

Output to induced draft fan

4. Implementation Details

The input to the PID control computation is the difference between the furnace pressure setpoint and the feedforward signal. The feedforward signal is typically proportional to the derivative of the air supply rate:

This configuration ensures that when airflow suddenly increases, the feedforward signal adjusts the PID input to reduce fan speed preemptively, preventing an overdrop in pressure. Conversely, a sudden drop in airflow leads to an increase in fan speed, compensating for the anticipated pressure rise.

📌 Note: Technically, this feedforward function is a derivative-only controller, with the proportional and integral actions set to zero.

5. Advantages and Considerations

✅ Benefits

Improved disturbance rejection

Reduced pressure fluctuation

Faster stabilization after input changes

⚠️ Considerations

Requires accurate feedforward modeling

Best suited for systems with measurable and predictable disturbances

Tuning is more complex than pure PID

6. Conclusion

Combining feedforward with PID control provides a robust control strategy for disturbance-sensitive processes. In furnace applications, where airflow fluctuations impact pressure significantly, feedforward control effectively reduces pressure oscillations. Proper implementation of this hybrid approach can lead to significant improvements in process stability and efficiency.