In engineering fields such as chemical, petroleum, pharmaceutical, and power generation, two key technical diagrams are widely used: the Process Flow Diagram (PFD) and the Piping and Instrumentation Diagram (P&ID). Although closely related, they serve distinct purposes at different stages of a project.

1. What Is a PFD?

Definition:

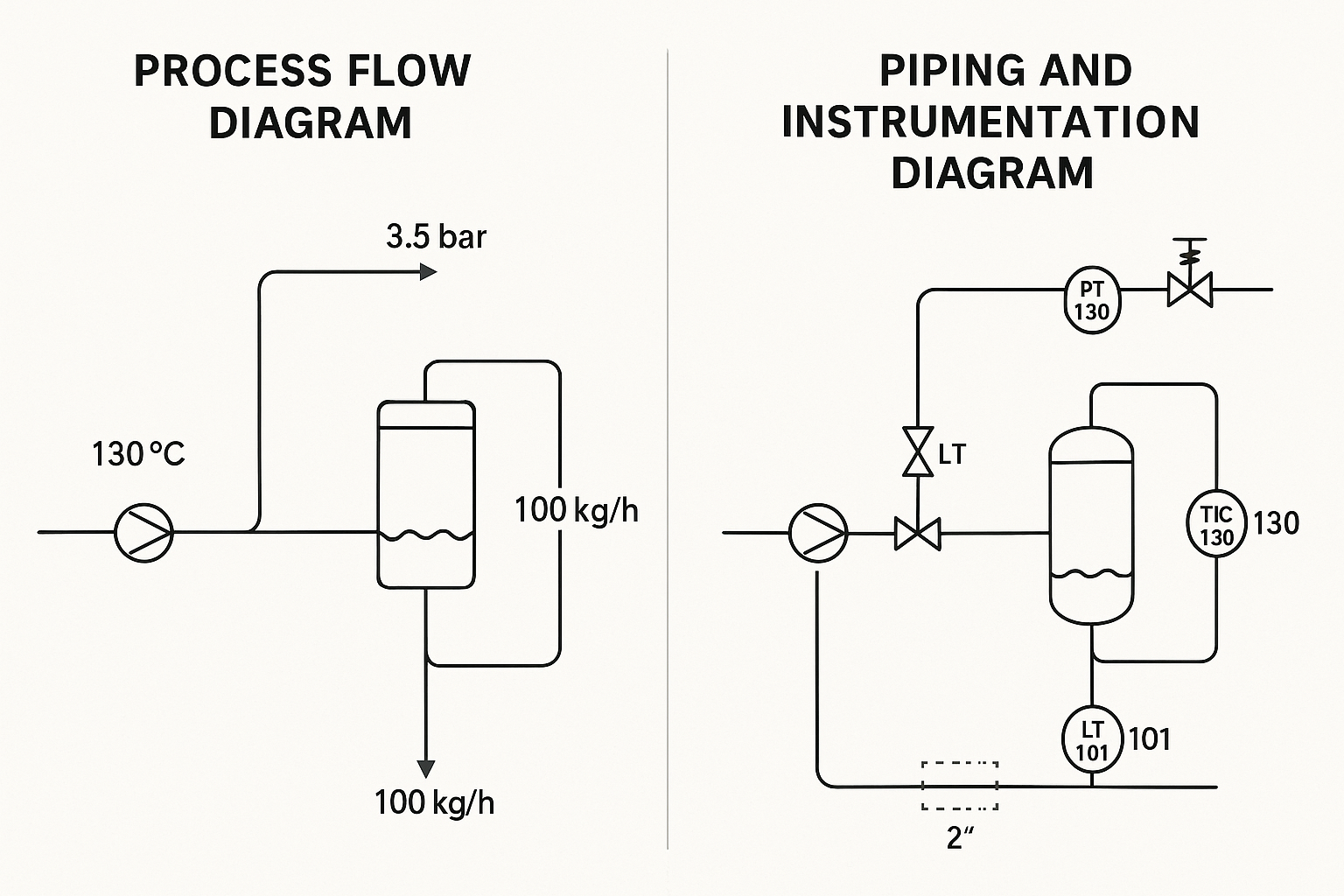

A Process Flow Diagram (PFD) provides a high-level overview of the entire process flow. It outlines the primary equipment and the direction of material flows, along with key process parameters such as temperature, pressure, and flow rate.

Main Features:

Focuses on the main process route rather than equipment details

Displays major equipment such as reactors, heat exchangers, pumps, and compressors

Shows material flows, directions, and labels

May include mass or energy balances

Limited representation of control systems (basic control loops only)

Does not include safety valves or detailed instrumentation

Applications:

Used in the conceptual and basic design phases

Supports material and energy balance calculations

Helps with equipment selection and process understanding across departments

Provides a foundation for further detailed design (e.g., P&ID development)

2. What Is a P&ID?

Definition:

A Piping and Instrumentation Diagram (P&ID) builds upon the PFD by incorporating detailed information about process piping, instrumentation, valves, and control systems. It is a critical reference during construction, commissioning, and operation.

Main Features:

Contains all equipment (main and auxiliary), piping, and instruments

Specifies piping details: tag numbers, pipe sizes, materials, pressure ratings, insulation/heating

Fully displays instrumentation and control systems:

Instrument symbols and tag numbers (e.g., FT, PT, TT)

Process control loops (e.g., feedback control with PID controllers)

Control system architecture (e.g., DCS, PLC)

Includes all types of valves (manual, control, check, relief, safety)

Incorporates safety and interlock systems (e.g., ESD, overpressure protection)

Applications:

Used as a primary document for construction and installation

Guides automation and control system design and programming

Supports maintenance, troubleshooting, and operation

Serves as the basis for safety analysis (e.g., HAZOP studies)

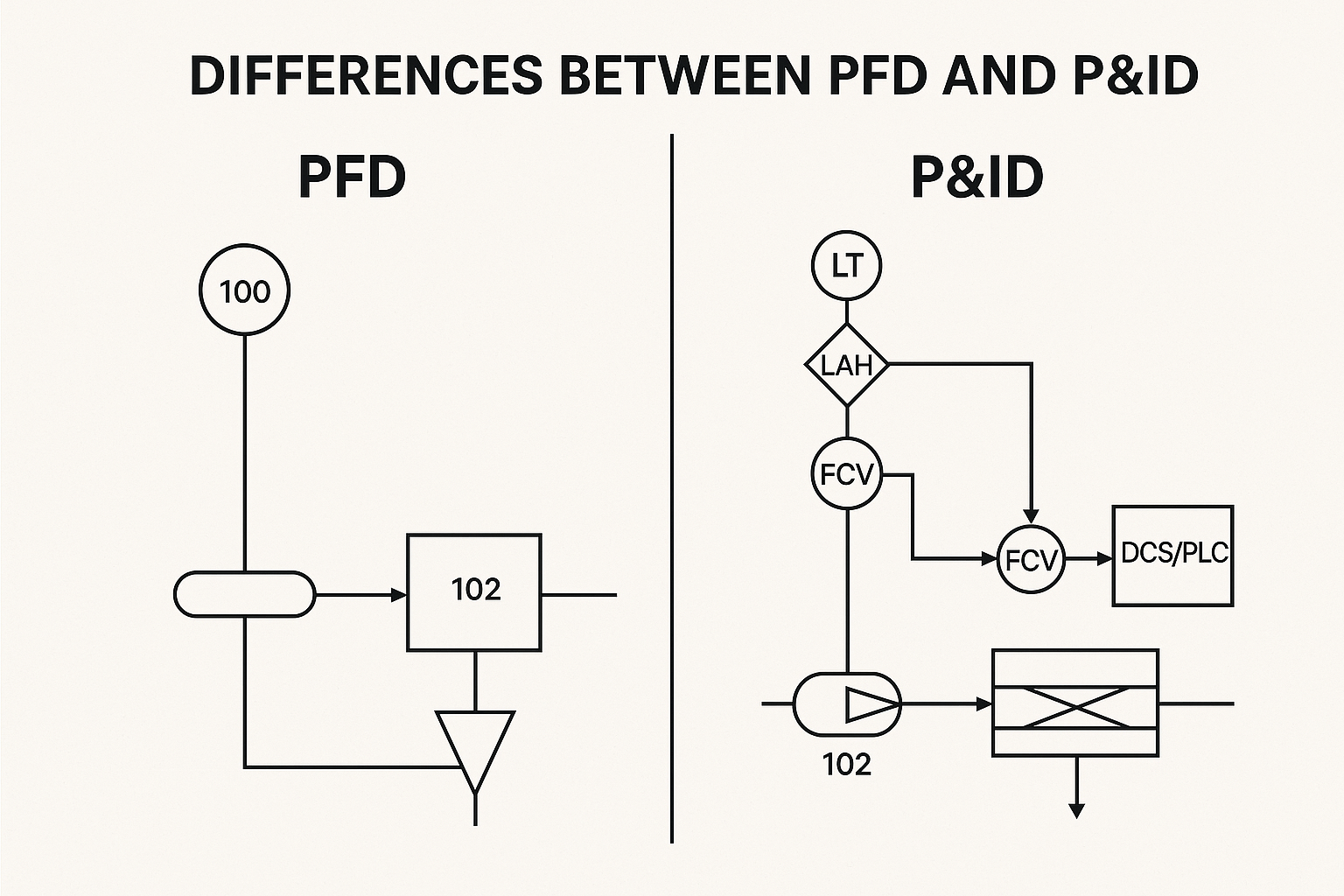

3. Key Differences Between PFD and P&ID

| Aspect | PFD (Process Flow Diagram) | P&ID (Piping and Instrumentation Diagram) |

|---|---|---|

| Purpose | High-level overview of process flow | Detailed design and implementation guide |

| Equipment Representation | Major equipment only | All equipment (including auxiliary units) |

| Piping Information | Simplified flow lines | Full piping details (size, material, spec) |

| Instrumentation | Minimal or symbolic | Complete instrument and control system representation |

| Control Loops | Basic (high-level) | Detailed, including logic and safety interlocks |

| Safety Devices | Usually not shown | Fully shown (e.g., PSV, shutdown systems) |

| Design Stage | Early stage (conceptual, feasibility, basic design) | Later stage (detailed design, construction, operation) |

| Main Users | Process engineers, management, technical overview | Process, piping, control, electrical, and safety engineers |

4. Summary

PFD offers a macro-level understanding of process engineering, ideal for early-stage design and process communication.

P&ID is a micro-level document essential for construction, automation, operation, and maintenance.

These diagrams are complementary—PFD comes first to establish the process, followed by P&ID for execution and control.

In real-world projects, both diagrams are indispensable, ensuring smooth transition from design to commissioning and operation.