Liquid level measurement is a critical process in various industrial and environmental applications, such as water treatment, chemical processing, and oil refining. The approach to measuring liquid levels varies significantly depending on whether the environment is sealed (closed) or unsealed (open). Each of these environments poses different challenges and requires distinct measurement techniques. In this article, we will explore the differences between liquid level measurement in sealed and unsealed environments, focusing on pressure conditions, measurement methods, and their applications.

1. Pressure Conditions

One of the most significant differences between sealed and unsealed environments lies in the pressure conditions at the liquid surface.

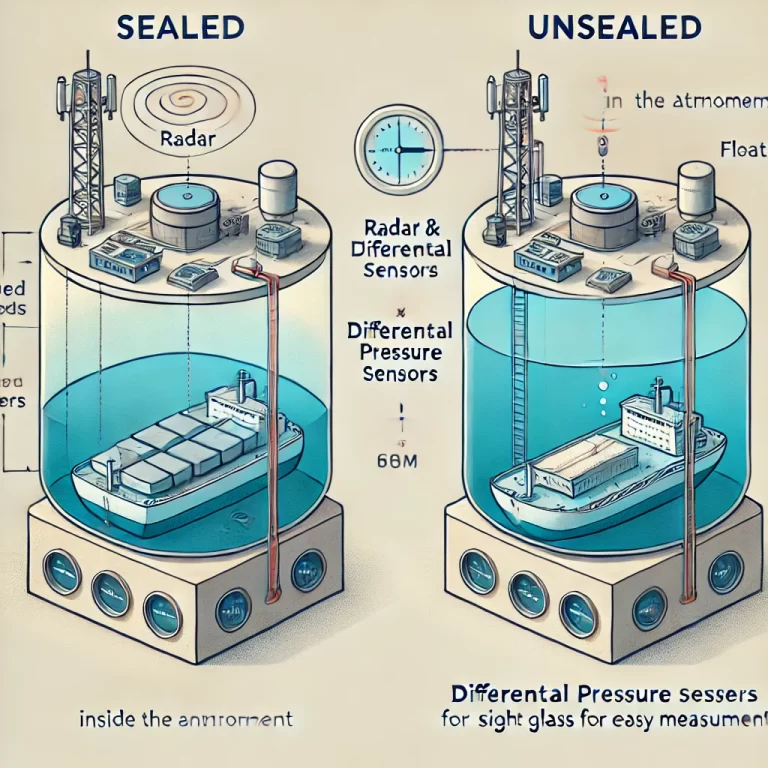

Sealed Environment: In a sealed environment, the liquid is contained within a closed vessel or tank, where the liquid surface is subjected to pressures other than atmospheric pressure. The pressure inside the vessel can be due to gases, vapors, or even liquids, creating an additional force on the liquid’s surface. This means that the liquid is influenced not only by gravity but also by the internal pressure within the container. These pressure variations must be accounted for when measuring the liquid level, as they can affect the accuracy of the readings.

Unsealed Environment: In an unsealed environment, such as an open tank or reservoir, the liquid surface is exposed to atmospheric pressure. The pressure exerted on the liquid’s surface is constant (typically atmospheric pressure), so the measurement process is simplified. Since there is no need to consider any additional pressure above the liquid, the system is less complex and does not require compensation for pressure variations.

2. Measurement Methods

Different measurement techniques are required to accurately measure liquid levels in sealed and unsealed environments, primarily due to the varying pressure conditions.

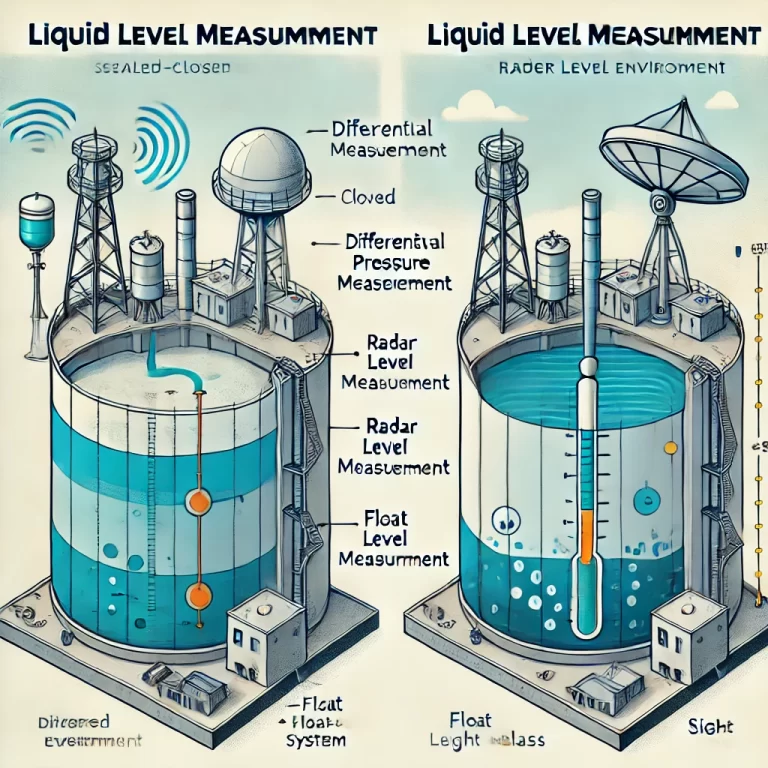

Liquid Level Measurement in Sealed Environments:

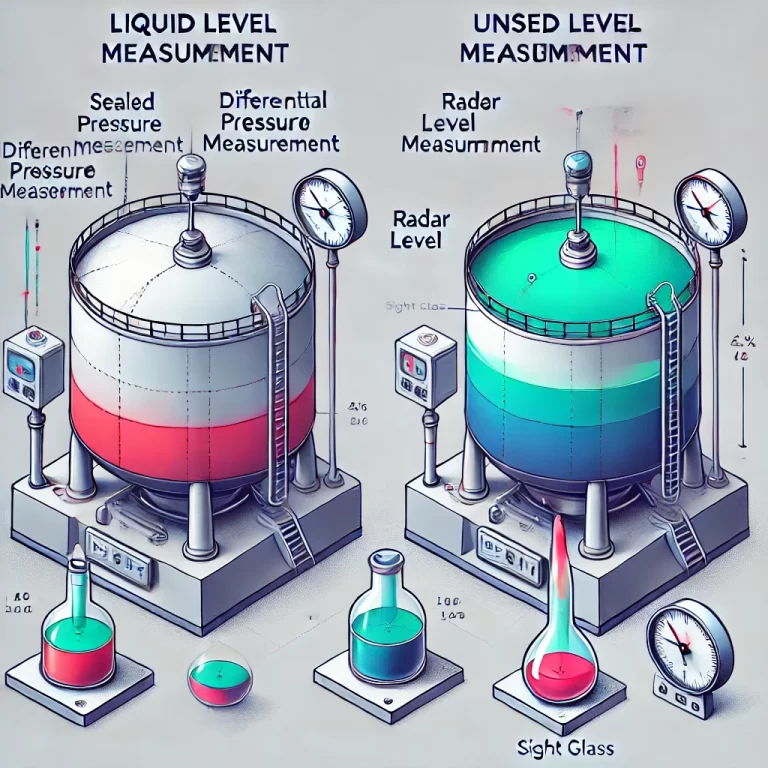

Differential Pressure Measurement: This method is widely used in sealed environments, especially in industries where the internal pressure of the vessel fluctuates. A differential pressure (DP) transmitter measures the pressure at two points: one at the bottom of the tank and the other at the top (or near the liquid surface). By calculating the difference between these two pressure readings, the level of the liquid can be determined. This method accounts for the additional gas or vapor pressure in the sealed vessel, ensuring an accurate liquid level reading.

Hydrostatic Pressure (Static Pressure) Measurement: This technique involves measuring the static pressure at the bottom of the tank, which is a function of the liquid’s height and density. In a sealed environment, the pressure at the liquid surface (caused by gas or vapor) must be subtracted from the total pressure to obtain the true liquid level. This method is effective but requires careful calibration to account for pressure variations inside the tank.

Capacitive and Radar Level Measurement: Capacitive sensors can be used in sealed environments, where the capacitance between a probe and the liquid changes with the liquid level. Radar level measurement involves sending radar waves that reflect off the liquid surface back to the sensor. Both methods can handle varying internal pressures, making them suitable for sealed containers where non-contact or highly precise measurements are needed.

Ultrasonic Level Sensors: In sealed tanks, ultrasonic level sensors use sound waves to detect the liquid level. They send a pulse of sound, and the time it takes for the echo to return is used to calculate the distance to the liquid surface. However, in sealed environments, the presence of vapors or gases at the top of the tank can affect the speed of sound, which must be compensated for.

Liquid Level Measurement in Unsealed Environments:

Float-Based Systems: One of the simplest and most commonly used methods in unsealed environments is the float-based system. A float rests on the liquid surface, rising and falling as the liquid level changes. The movement of the float is linked to a mechanical indicator or transmitter, which shows the liquid level. Since the environment is open to atmospheric pressure, the measurement is straightforward, with no need for pressure compensation.

Transparent Tube or Sight Glass: In unsealed environments, a transparent tube, also known as a sight glass, can be used to measure liquid levels. This tube is connected to the tank at two points, allowing the liquid to flow freely between the tank and the tube. The level in the tube mirrors the level in the tank, providing a direct visual indication. This method is simple, inexpensive, and effective in many open-tank applications.

Ultrasonic and Radar Sensors: Ultrasonic and radar sensors are also widely used in unsealed environments, where they measure the time taken for sound or electromagnetic waves to travel to the liquid surface and reflect back. In these cases, the measurements are less complex than in sealed environments because there is no need to account for pressure variations. These sensors offer the advantage of being non-contact, making them ideal for corrosive or hazardous liquids.

3. Application Areas

The choice of liquid level measurement method depends on the specific application and the nature of the environment—whether it is sealed or unsealed.

Sealed Environment Applications: Sealed environments are commonly found in industries such as chemical processing, oil and gas, pharmaceuticals, and food production. In these settings, liquids are stored in pressurized or vacuum-sealed vessels, where precise level measurements are critical for safety, efficiency, and quality control. Differential pressure and radar-based methods are often used in these environments to ensure accurate and reliable level readings despite varying internal pressures.

Unsealed Environment Applications: Unsealed environments are typically seen in water treatment plants, open reservoirs, and storage tanks where the liquid is exposed to the atmosphere. In these applications, float-based systems, sight glasses, and ultrasonic sensors are commonly used because they are simple, reliable, and easy to maintain. Since there are no pressure variations to consider, the measurement process is more straightforward.

Conclusion

The primary differences between liquid level measurement in sealed and unsealed environments stem from the pressure conditions and the complexity of the measurement methods required. Sealed environments involve pressure variations that must be accounted for, making the measurement process more complex and requiring advanced techniques like differential pressure, radar, or capacitive sensors. In contrast, unsealed environments are exposed to atmospheric pressure, allowing for simpler and more cost-effective measurement methods such as float-based systems or ultrasonic sensors. By understanding these differences, operators can select the most appropriate measurement technique for their specific applications, ensuring accurate and reliable liquid level monitoring.