Although their names differ by only one word, capsule pressure gauges and diaphragm pressure gauges are fundamentally different in structure, working principle, applicable media, and usage scenarios. Understanding their distinctions is essential for proper selection and application.

⚙️ 1. Working Principle

● Capsule Pressure Gauge

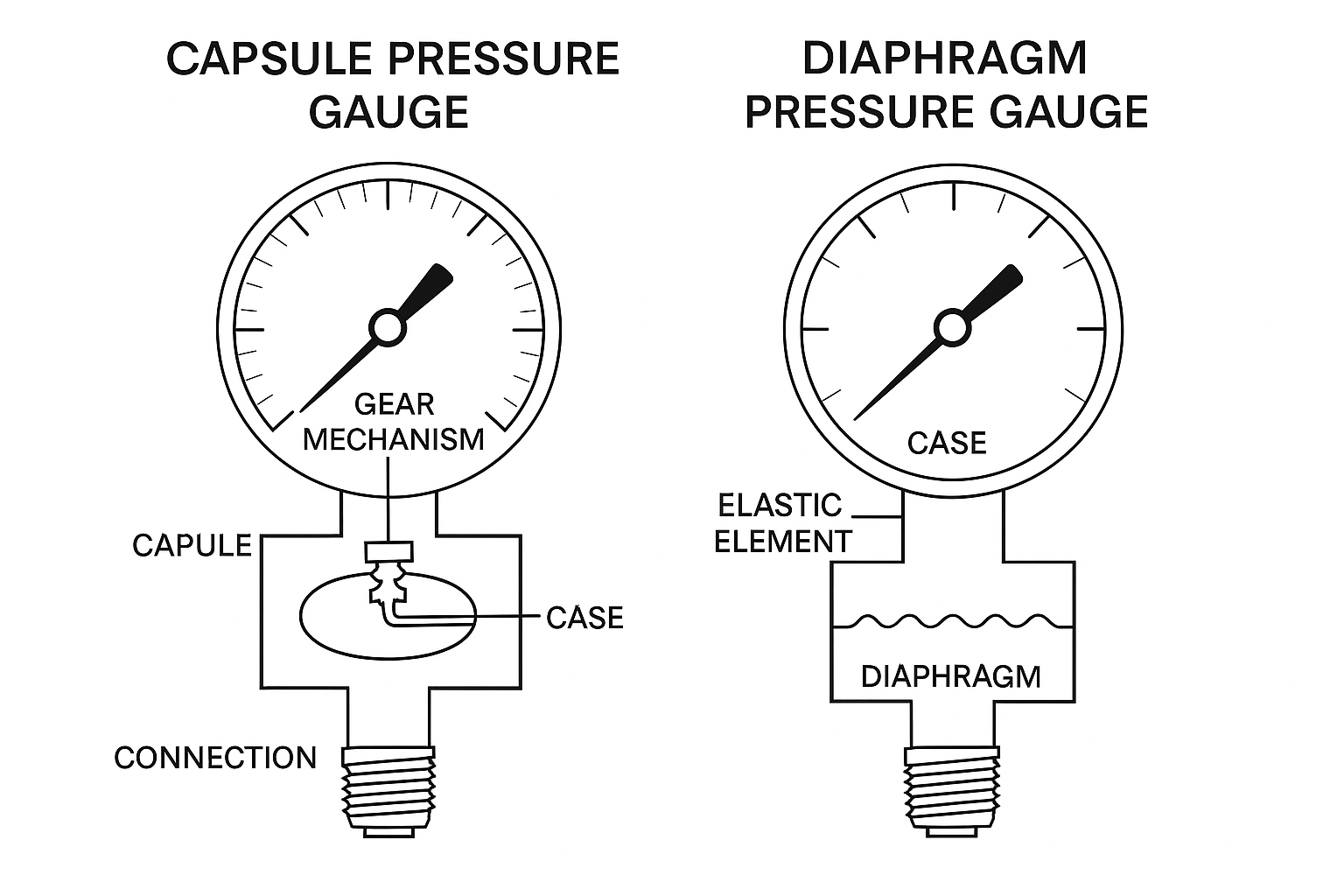

A capsule pressure gauge uses a pressure-sensitive element called a capsule. It is made by welding two thin, corrugated diaphragms together to form an enclosed chamber. When pressure is applied, the capsule deforms elastically, and the resulting displacement is transmitted and amplified through a mechanical gear mechanism, causing the pointer to indicate the measured pressure on the dial.

Typical measuring range: 0.001 MPa to 4 MPa

● Diaphragm Pressure Gauge

A diaphragm pressure gauge consists of a diaphragm isolator, a general-purpose pressure gauge (e.g., Bourdon tube), and a sealed fill fluid system. The measured medium applies pressure to the diaphragm, which deforms and transmits force to the sealed liquid. This liquid then transfers the pressure to the sensing element inside the pressure gauge, causing the pointer to indicate the pressure value.

Typical measuring range: 0.1 MPa to 40 MPa

🛠️ 2. Structural Features

● Capsule Pressure Gauge

Components: Capsule element, gear transmission, pointer, dial, case, and window

Structure: Relatively simple and compact

Performance: Good anti-vibration capability and temperature tolerance

Design Use: Suited for micro-pressure measurement of clean, non-corrosive gases

● Diaphragm Pressure Gauge

Components: Diaphragm isolator, general-purpose pressure element, and fill fluid

Structure: More complex due to the isolator and liquid system

Performance: Excellent corrosion resistance and hygiene; isolator prevents the medium from entering the pressure gauge

Design Use: Ideal for challenging media such as viscous, corrosive, or crystallizing substances

🧪 3. Applicable Media & Scenarios

| Type | Applicable Media | Typical Industries | Notes |

|---|---|---|---|

| Capsule Pressure Gauge | Clean, dry, non-corrosive gases (e.g., air, flue gas) | HVAC, boiler ventilation, gas pipelines | For micro-pressure and negative pressure measurement |

| Diaphragm Pressure Gauge | Corrosive, viscous, high-temp, or solid-laden fluids | Petrochemical, alkali, pharmaceutical, food, dyeing | Can be customized with different diaphragm materials (e.g., PTFE, Monel, Hastelloy) |

📊 4. Summary Comparison Table

| Feature | Capsule Pressure Gauge | Diaphragm Pressure Gauge |

|---|---|---|

| Sensing Element | Capsule | Diaphragm with isolator |

| Pressure Range | 0.001 MPa – 4 MPa | 0.1 MPa – 40 MPa |

| Media | Non-corrosive gases | Corrosive, viscous, or dirty fluids |

| Structure | Simple | Complex |

| Cleaning | Not suitable for dirty media | Easy to clean and maintain |

| Cost | Lower | Higher |

✅ 5. Conclusion & Selection Tips

Both types of gauges have their place in pressure measurement applications:

Use a capsule pressure gauge when measuring low pressure or vacuum in non-corrosive gas systems, especially when high precision is needed.

Choose a diaphragm pressure gauge for aggressive, viscous, or solid-containing fluids, or when hygiene and corrosion resistance are critical.

📌 Tip: Never substitute one for the other without confirming media compatibility and pressure range — incorrect selection can lead to measurement errors or equipment damage.