1. Introduction

Coriolis mass flow meters are precision instruments designed to directly measure the mass flow rate of fluids. Unlike volumetric flow meters, they are unaffected by temperature, pressure, and density changes, making them highly suitable for applications requiring accurate mass measurements.

There are two main types of mass flow meters:

Coriolis Mass Flow Meter

Thermal Mass Flow Meter

This document focuses on the structure, principle, installation, wiring, and troubleshooting of Coriolis mass flow meters using a brand-neutral perspective.

2. Working Principle

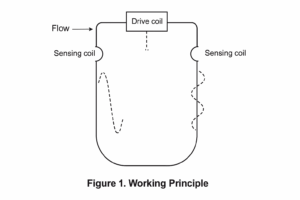

Coriolis meters operate by vibrating dual measuring tubes through an electromagnetic coil. The presence of fluid causes a Coriolis effect—twisting of the vibrating tubes—which is directly proportional to mass flow.

Figure 1: Working Principle Diagram

No flow: Tubes vibrate in phase

Flow present: Phase shift occurs between inlet and outlet ends

Signal Processing:

Drive coil maintains vibration

Two pickup coils detect phase shift

Mass flow calculated from the time difference between coils

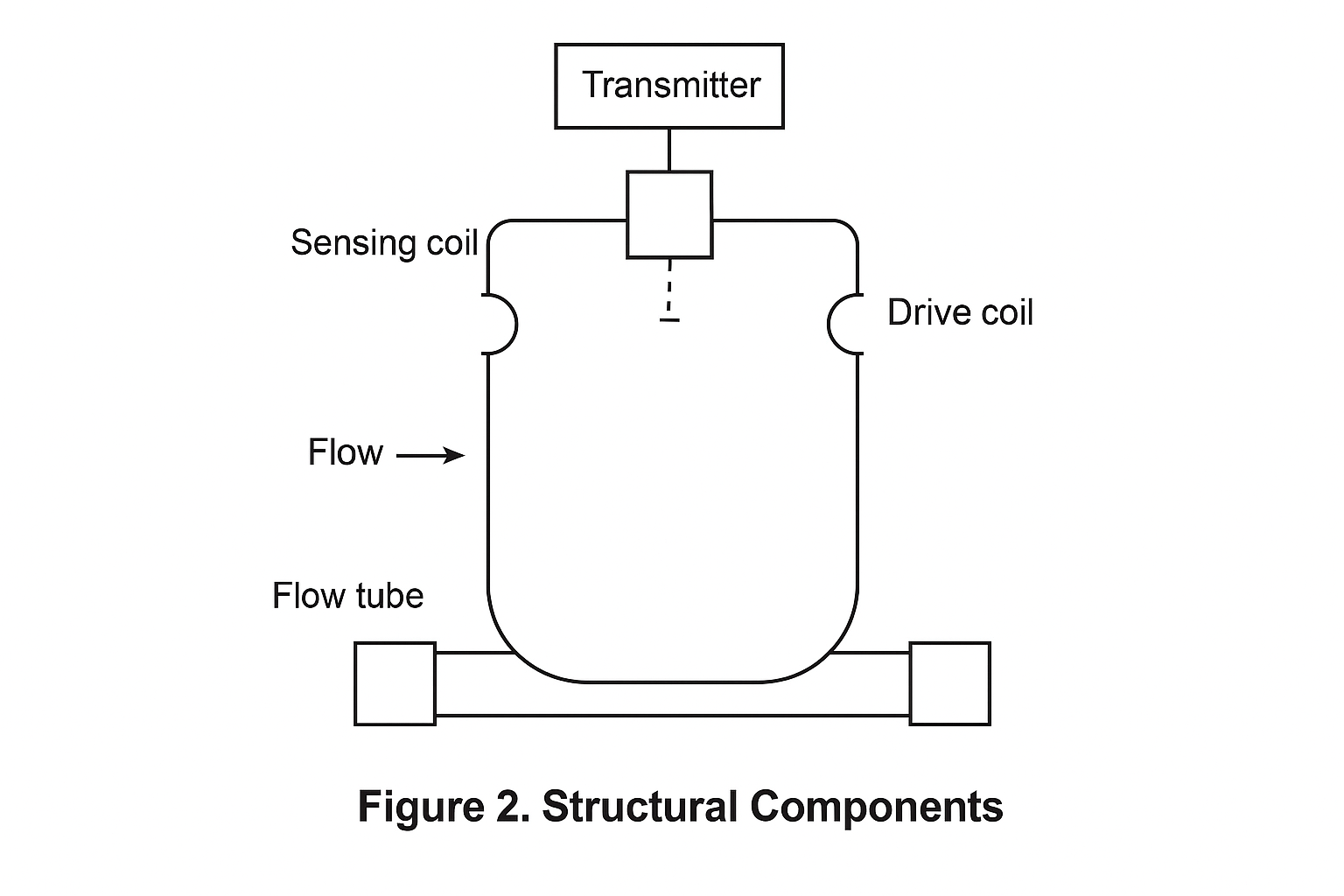

3. Meter Structure

Most Coriolis flow meters consist of:

Dual measuring tubes (U-shaped or straight)

Drive coil

Two pick-up coils (sensors)

Flow divider and flow manifolds

Transmitter housing (integrated or remote)

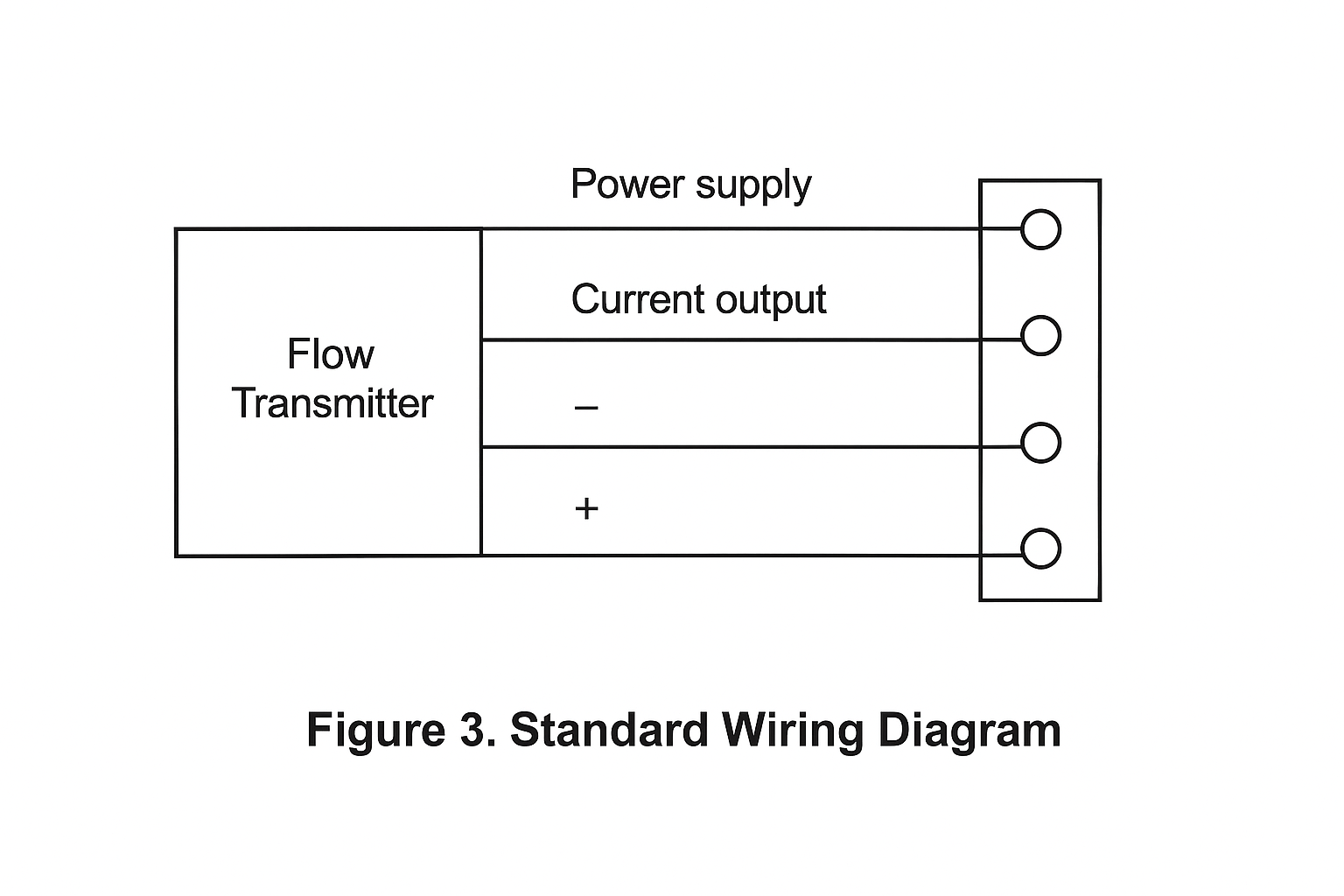

4. Electrical Wiring

Wiring varies by manufacturer, but standard industrial configurations include:

4–20mA output: Terminals 1–2

Pulse/frequency output: Terminals 3–4

RS-485 digital output: Terminals 5–6

Power supply (24VDC or 220VAC): Terminals 9–10

Sensor Wiring Colors (Typical):

Drive coil: Brown (+), Red (–)

Sensor coil 1: Green (+), White (–)

Sensor coil 2: Blue (+), Grey (–)

PT100: Violet, Orange, Yellow (3-wire RTD)

5. Installation Considerations

No straight pipe requirement, but sufficient space is needed for the meter body

Bidirectional measurement supported, but must match configuration direction

Support required near flanges to prevent stress from heavy body weight

Avoid vibration sources (e.g., pumps, compressors)

For vertical pipelines, liquid flow should be upward, gas flow can be upward or downward

Control valves should be installed downstream

For viscous or crystallizing media, ensure insulation or heating

6. Common Field Questions

| Question | Answer |

|---|---|

| Is a straight pipe required? | No, but support is essential. |

| Can it measure reverse flow? | Yes, if properly configured. |

| Does vibration affect accuracy? | Yes, avoid external vibrations. |

| 24VDC vs 220VAC: Any performance difference? | No, just power supply type. |

| Recommended zero-point check frequency? | Every 3 months. |

| Should the meter be removed during pipeline purging? | Yes, always. |

| Self-drain or cleaning for special fluids? | Yes, must be considered. |

| Is heat tracing needed? | Only if fluid requires it to prevent solidification. |

7. Sensor Connector Pinout (9-Pin Plug Example)

| Pin | Function |

| 1 | Drive Coil (+) |

| 2 | Drive Coil (–) |

| 3 | Sensor Coil 1 (+) |

| 4 | Sensor Coil 1 (–) |

| 5 | Sensor Coil 2 (+) |

| 6 | Sensor Coil 2 (–) |

| 7 | PT100 Wire A |

| 8 | PT100 Wire B |

| 9 | PT100 Wire C |

8. Troubleshooting Cases

Case 1: Accuracy Lower than Expected

Symptoms: Field accuracy at ~0.3% vs expected 0.15%

Cause: Installed near vibration source; weak pipeline supports; unfilled pipe during operation

Solution: Increase distance from pump; strengthen supports; adjust valve for full pipe condition

Case 2: Cumulative Error After Pipeline Modification

Symptoms: Cumulative reading shows 8t; level gauge shows 5.7t

Cause: New pipe stress or partial flow due to air pockets or improper support

Solution: Reinforce support, ensure stress-free piping

Case 3: Sudden Jump in Flow Reading

Symptoms: Flow jumps from 2600 to 4200 Kg/h without process change

Cause: Possible transmitter program issue or electrical interference

Solution: Reboot or reprogram transmitter; inspect for EMI sources; check wiring

Case 4: Communication Fault A266

Symptoms: Zero data, alarm A266

Cause: Core processor disconnected or noise interference

Solution: Check wiring integrity, perform LED/power/resistance check, replace core if needed

9. Summary

Coriolis mass flow meters offer direct, accurate mass flow measurements across a wide range of applications. Proper installation, support, and environmental management are essential for reliable performance. Routine zero-point calibration and understanding fault codes can extend the service life and ensure operational consistency.