1. Basic Principle

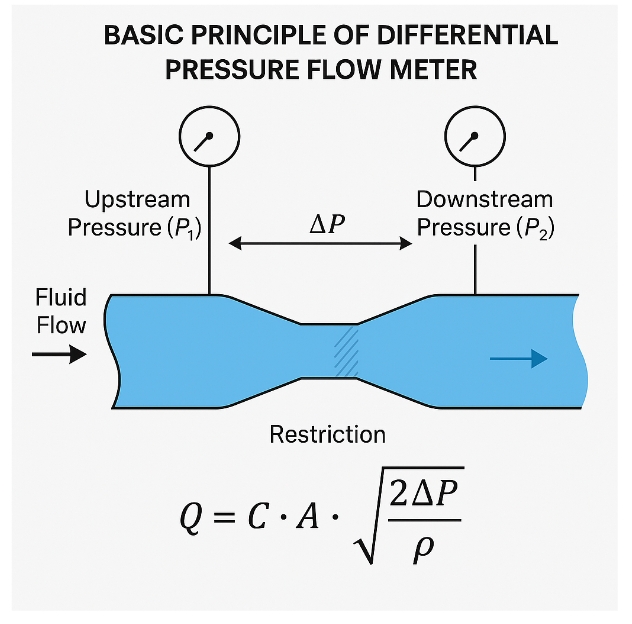

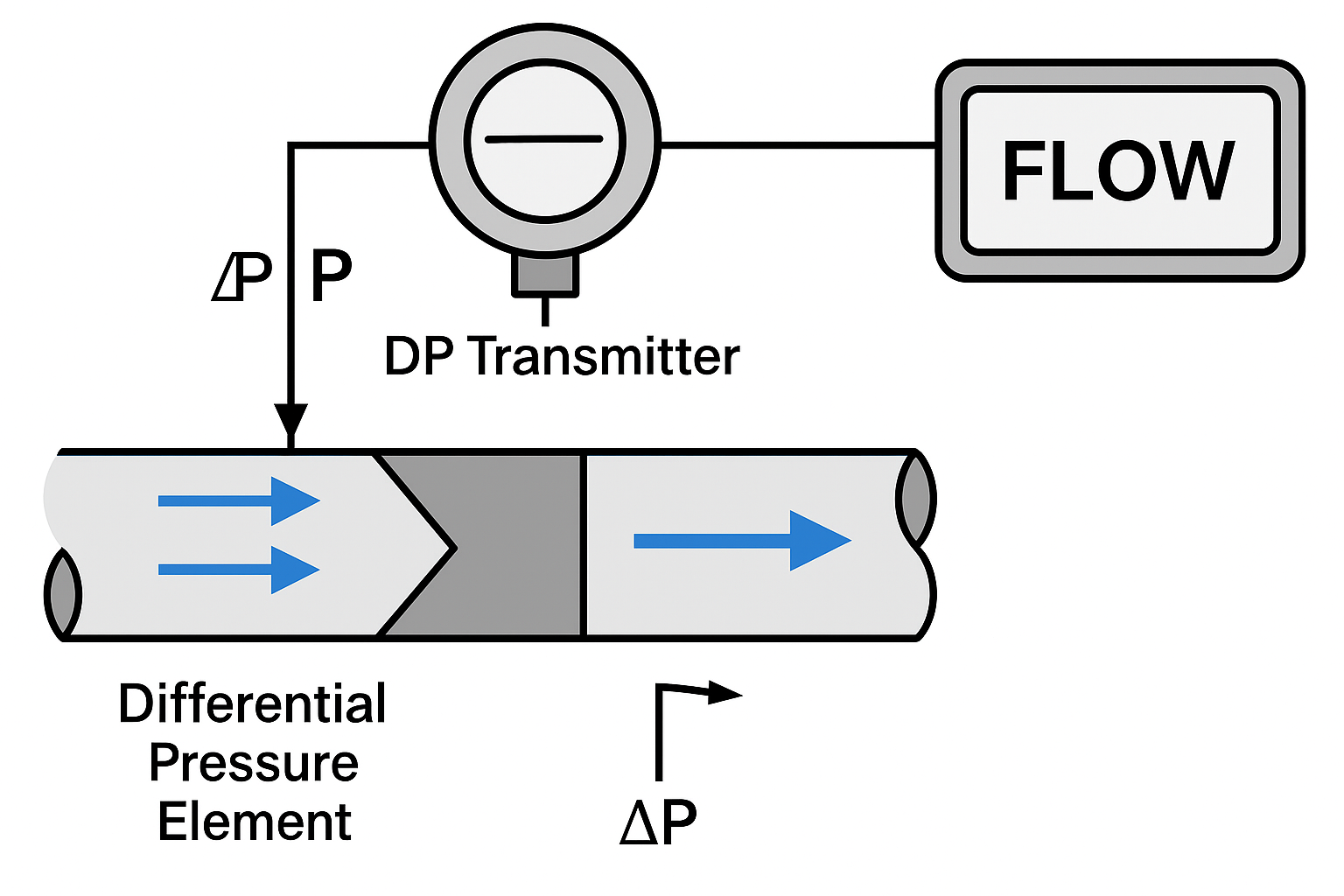

Differential pressure (DP) flow meters operate based on the throttling principle derived from Bernoulli’s equation. As fluid flows through a restriction (e.g., orifice plate, nozzle, or Venturi tube), its velocity increases and static pressure decreases, creating a pressure differential (ΔP) that correlates to flow rate.

Working Formula:

Where:

Q = volumetric flow rate

C = flow coefficient (depends on device geometry and Reynolds number)

A = throat cross-sectional area

ΔP = pressure differential

ρ = fluid density

2. Classification and Throttling Devices

| Type | Structure & Features | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| Orifice Plate | Circular bore in a flat plate | Standardized, low cost, easy installation | High pressure loss, moderate accuracy (±1–2%) | Clean gases or liquids |

| Nozzle | Curved inlet, cylindrical outlet | Higher accuracy (±0.5–1%), lower pressure drop | Complex machining, higher cost | High-speed fluids, high Reynolds number |

| Venturi Tube | Converging throat + diverging section | Lowest pressure loss, high accuracy (±0.5%) | Bulky, high cost, large space required | Large diameter pipelines, water flow |

| Wedge Flowmeter | Sharp-edged V-shape restriction | Resistant to clogging, handles slurry/viscous fluids | Custom-built, needs individual calibration | Slurries, suspended solids |

| Averaging Pitot (Annubar) | Multi-port velocity probe | Very low pressure drop, easy to install | Low accuracy (±1.5–3%), sensitive to flow profile | Gases, steam, clean liquids |

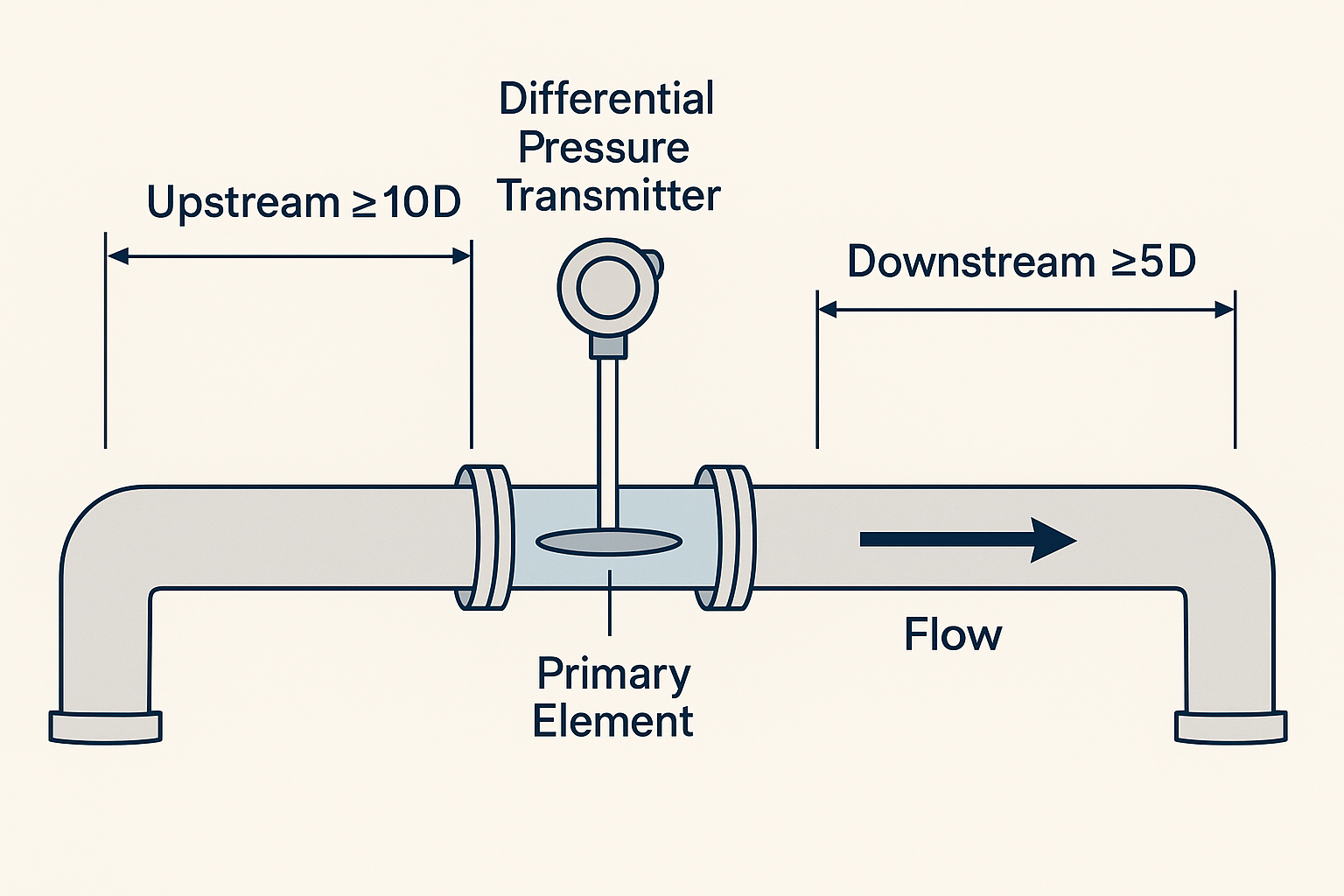

3. System Components

Primary Element (Restriction): Generates differential pressure.

Differential Pressure Transmitter: Converts ΔP, temperature, and pressure signals into standard outputs (4–20 mA, HART, Modbus) and compensates fluid density.

Display & Computing Unit: Calculates instantaneous and total flow; can interface with DCS or remote systems.

4. Technical Features

Strengths:

Universal Use: Suitable for gas, liquid, and steam over wide temperature (–200°C to 850°C) and pressure (0–40 MPa) ranges.

High Standardization: Devices comply with ISO 5167, GB/T 2624 standards, reducing calibration needs.

Mature Technology: Extensive industrial experience and reliability.

Limitations:

Pressure Loss: Especially high in orifice plates; Venturi offers minimal loss.

Limited Turn-down Ratio: Typically 3:1 to 5:1, requiring precise sizing.

Strict Installation: Requires long upstream/downstream straight pipe (10–30D upstream, 5–10D downstream).

Media Sensitivity: Changes in density, viscosity, and Reynolds number affect accuracy; clogging risk with dirty media.

5. Installation Considerations

Straight Pipe Requirements:

Orifice: ≥10D upstream (no elbows), ≥30D (with elbows), ≥5D downstream.

Venturi: ≥10D upstream, ≥5D downstream.

Pressure Tapping Methods:

Corner taps, flange taps, D and D/2 taps (used in Venturi meters).

Tap piping should be short, sloped (upward for gas, downward for liquid), and avoid mixed-phase flows.

Orientation:

Horizontal: side taps for liquids, top taps for gases.

Vertical: flow should be from bottom to top.

Sealing & Coaxiality:

The restriction must be aligned with the pipe; gaskets must not protrude into the flow.

6. Applications

Petrochemical: Oil, gas, steam flow measurement.

Power Plants: Main steam, air flow, circulating water.

Metallurgy & Cement: Blast furnace gas, slurry, compressed air.

Water Utilities: Municipal water, wastewater, irrigation (Venturi meters preferred).

Energy Management: Industrial gas and steam energy tracking.

7. Maintenance and Troubleshooting

Routine Maintenance:

Inspect and clean tapping lines.

Drain condensate (for gas service).

Zero calibration for DP transmitters.

Clean or backflush restriction elements for dirty media.

Common Faults:

| Issue | Possible Causes |

|---|---|

| Abnormal ΔP | Clogged taps, worn restriction, sealing leaks |

| Zero Shift | Transmitter drift, temperature changes, lack of compensation |

| Accuracy Drop | Inadequate straight runs, low Reynolds number |

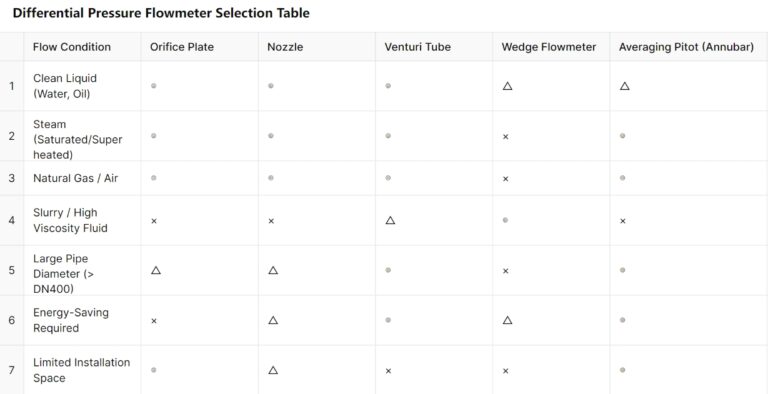

8. Selection Guidelines

| Factor | Key Considerations |

|---|---|

| Medium | Cleanliness, viscosity, corrosiveness (material selection: 316L, Hastelloy) |

| Operating Conditions | Pipe size (DN15–DN2000+), pressure, temperature, flow range |

| Accuracy | Orifice (±1–2%), Nozzle (±0.5–1%), Venturi (±0.5%) |

| Pressure Drop | Minimize in energy-critical systems (prefer Venturi) |

| Installation | Available space, straight-run length, online maintenance needs |

9. Comparison with Other Flow Meters

| Type | Advantages | Limitations | Typical Use Cases |

|---|---|---|---|

| DP Flow Meter | Versatile, standardized | High pressure drop, narrow range | Harsh or complex process conditions |

| Vortex Meter | No moving parts, wide range | Sensitive to vibration, inaccurate at low flow | Clean gas/liquid (e.g., air, water) |

| Magnetic Meter | No pressure loss, high accuracy | Only for conductive fluids, expensive | Slurries, corrosive fluids, wastewater |

| Ultrasonic Meter | Non-invasive, suitable for large pipelines | Accuracy depends on sound path, full pipe required | Water, large-diameter industrial flow |

10. Future Trends

Intelligent Functions: Built-in diagnostics, temperature/pressure compensation, predictive maintenance.

Wireless & Low Power: Ideal for remote gas distribution and energy management.

Custom Engineering: New restriction elements for challenging fluids (slurry, multiphase).

Digital Verification: CFD simulation reduces lab testing costs and improves design accuracy.

Conclusion

Differential pressure flow meters remain a cornerstone in industrial flow measurement due to their versatility and standardization. However, careful consideration must be given to installation conditions, maintenance, and media properties. When combined with modern intelligent features, DP flow meters can achieve greater efficiency, reliability, and adaptability in evolving industrial environments.